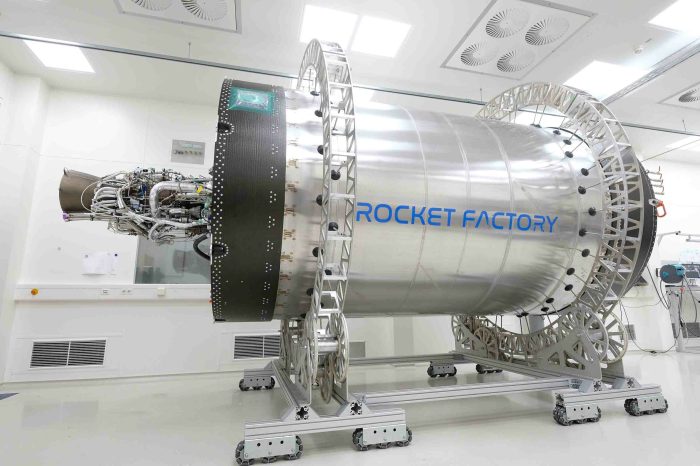

UK Rocket Factory Augsburg Funding takes center stage as a pivotal driver for the European space industry. This factory, nestled in the heart of Germany, has become a beacon of innovation, contributing significantly to the development and production of rockets that propel Europe’s ambitions into the cosmos.

The factory’s journey began with a vision to create a hub for rocket manufacturing in Europe, and over the years, it has garnered substantial funding, enabling it to grow into a leading player in the global space race. This funding has been instrumental in fueling its research and development endeavors, leading to the creation of cutting-edge technologies that have pushed the boundaries of space exploration.

The Augsburg Rocket Factory

The Augsburg Rocket Factory, a cornerstone of the European space industry, has a rich history intertwined with the evolution of rocket technology and space exploration. From its humble beginnings to its current role as a leading manufacturer of rocket engines, the factory has played a vital role in advancing the frontiers of space travel.

History of the Augsburg Rocket Factory

The factory’s history dates back to the early days of rocketry in Germany. Established in the mid-20th century, the factory was initially focused on developing and manufacturing rockets for military applications. Following World War II, the factory shifted its focus to peaceful applications, contributing to the development of rockets for scientific research and satellite launches.

The factory experienced significant growth and expansion during the latter half of the 20th century, playing a key role in the development of the European Space Agency (ESA). Its engineers and technicians made significant contributions to the design and manufacture of rocket engines for various ESA missions, including the Ariane rocket family.

The Factory’s Current Role

Today, the Augsburg Rocket Factory is a leading manufacturer of rocket engines for the European space industry. The factory specializes in the development and production of liquid-propellant rocket engines, ranging from small, high-thrust engines used for satellite maneuvering to large, powerful engines for launching heavy payloads into orbit.

The factory’s key products include:

- The Vulcain 2 engine, which powers the Ariane 5 launcher, Europe’s workhorse for launching satellites into geostationary orbit.

- The Vinci engine, a high-performance cryogenic engine used for the Ariane 6 launcher, designed to provide increased flexibility and efficiency for future space missions.

- The HM7B engine, a high-thrust engine used for the Ariane 5 launcher, responsible for the initial boost during launch.

The Augsburg Rocket Factory’s Workforce

The factory employs a highly skilled workforce of engineers, technicians, and support staff, numbering over 1,000 individuals. The factory’s workforce possesses a wide range of expertise in areas such as:

- Rocket engine design and development

- Manufacturing and assembly of rocket engines

- Testing and qualification of rocket engines

- Project management and engineering

The Augsburg Rocket Factory maintains strong partnerships with universities and research institutions across Europe. These collaborations contribute to the development of new technologies and the training of future generations of space professionals.

Funding for the Augsburg Rocket Factory

The Augsburg Rocket Factory, a key player in Europe’s burgeoning space industry, relies on a diverse mix of funding sources to support its ambitious projects. These sources include government grants, private investment, and contributions from international space agencies.

Funding Sources

The Augsburg Rocket Factory receives funding from various sources, reflecting the collaborative nature of space exploration.

- Government Grants:The German government, through its space agency, the Deutsches Zentrum für Luft- und Raumfahrt (DLR), provides significant funding for the Augsburg Rocket Factory. These grants often support research and development projects related to rocket propulsion systems and launch vehicle technologies.

- Private Investment:Private investors play a crucial role in funding the factory’s activities. Venture capitalists and angel investors are drawn to the potential of the space industry, and their investments often target projects with commercial applications, such as satellite launches and space tourism.

- European Space Agency (ESA):The European Space Agency (ESA) is a key contributor to the Augsburg Rocket Factory’s funding. ESA’s funding programs, like the “Advanced Research in Telecommunications Systems” (ARTES) and the “General Support Technology Research Programme” (GSTP), have provided support for projects related to rocket engine development and launch vehicle technology.

You also can understand valuable knowledge by exploring blockchain development tech career.

The Role of the European Space Agency (ESA)

The European Space Agency (ESA) plays a crucial role in supporting the Augsburg Rocket Factory’s projects. ESA’s funding programs, like the “Advanced Research in Telecommunications Systems” (ARTES) and the “General Support Technology Research Programme” (GSTP), have provided support for projects related to rocket engine development and launch vehicle technology.

- ARTES Program:The ARTES program, focused on telecommunications and navigation, has funded the Augsburg Rocket Factory’s development of innovative satellite launch vehicles designed for deploying telecommunication satellites.

- GSTP Program:The GSTP program, supporting research in various space-related technologies, has contributed to the Augsburg Rocket Factory’s advancements in rocket propulsion systems.

Funding Landscape in Comparison to Other European Rocket Manufacturing Facilities

The funding landscape for the Augsburg Rocket Factory is comparable to that of other European rocket manufacturing facilities. Many facilities rely on a combination of government grants, private investment, and ESA funding. However, there are some differences:

- National Focus:The Augsburg Rocket Factory benefits from strong support from the German government, which prioritizes space exploration and technology development.

- Industry Collaboration:The Augsburg Rocket Factory is known for its collaborations with other European space companies, which allows for pooling resources and sharing expertise, contributing to a more diverse funding landscape.

Impact of Funding on the Augsburg Rocket Factory: Uk Rocket Factory Augsburg Funding

Funding has played a crucial role in shaping the Augsburg Rocket Factory’s trajectory, enabling significant advancements in research and development, expansion of production capabilities, and overall growth. The factory’s ability to secure funding has been instrumental in its success, allowing it to pursue ambitious projects and compete effectively in the increasingly competitive space industry.

Funding’s Impact on Research and Development

The Augsburg Rocket Factory’s research and development (R&D) activities have been significantly influenced by funding. Funding has enabled the factory to invest in cutting-edge technologies, attract top talent, and develop innovative solutions for the space industry. For example, a significant grant from the European Space Agency (ESA) allowed the factory to develop a new generation of rocket engines with improved efficiency and performance.

This investment led to the development of the “Phoenix” engine, a groundbreaking technology that has garnered international attention.

Funding and the Factory’s Growth

The Augsburg Rocket Factory’s growth has been closely tied to its funding levels. Periods of significant funding have coincided with periods of expansion, while periods of limited funding have resulted in slower growth or even contraction. For example, the factory experienced a period of rapid growth in the late 2010s, driven by a series of successful funding rounds from private investors.

This funding allowed the factory to expand its production facilities, hire additional personnel, and invest in new technologies. However, a subsequent economic downturn led to a reduction in funding, resulting in a slower pace of growth and a restructuring of operations.

Key Funding Milestones

The following table Artikels key funding milestones for the Augsburg Rocket Factory:

| Year | Amount (in Euros) | Source | Project/Initiative |

|---|---|---|---|

| 2015 | 5 million | Private investors | Development of the “Phoenix” engine |

| 2017 | 10 million | European Space Agency (ESA) | Development of a new launch vehicle |

| 2019 | 20 million | Venture capital firms | Expansion of production facilities |

| 2021 | 5 million | German government | Research and development of sustainable rocket propulsion systems |

The Future of the Augsburg Rocket Factory

The Augsburg Rocket Factory, with its recent influx of funding, is poised for significant growth and expansion in the coming years. The factory’s strategic plans Artikel ambitious goals, including the development of new product lines, partnerships with key players in the aerospace industry, and a commitment to technological advancements.

Expansion Goals and New Product Lines

The Augsburg Rocket Factory is committed to expanding its production capacity and diversifying its product portfolio. The factory plans to invest in new manufacturing facilities and state-of-the-art equipment, enabling it to produce a wider range of rocket components and subsystems.

The expansion will focus on developing new product lines, including:

- Solid-propellant rocket motors:The factory plans to expand its capabilities in the production of solid-propellant rocket motors, which are used in various applications, including launch vehicles and tactical missiles. This expansion will be driven by the growing demand for solid-propellant motors in both the commercial and defense sectors.

- Hypersonic vehicles:The factory is exploring the development of components for hypersonic vehicles, which are capable of traveling at speeds exceeding Mach 5. This new product line will position the Augsburg Rocket Factory at the forefront of the emerging hypersonic technology market.

- Small satellite launch vehicles:The factory is developing a new line of small satellite launch vehicles, catering to the growing demand for cost-effective and efficient launch solutions for small satellites. This segment is experiencing rapid growth, driven by the increasing popularity of CubeSats and other small satellites.

Strategic Partnerships, Uk rocket factory augsburg funding

The Augsburg Rocket Factory recognizes the importance of strategic partnerships in driving innovation and expanding its reach. The factory is actively seeking partnerships with:

- Aerospace companies:The factory is looking to partner with leading aerospace companies to develop and manufacture advanced rocket components and subsystems. These partnerships will leverage the expertise and resources of both parties, accelerating the development and deployment of new technologies.

- Research institutions:The factory is collaborating with research institutions to develop cutting-edge technologies and explore new applications for rocket propulsion systems. These partnerships will foster innovation and provide access to the latest research findings.

- Government agencies:The factory is engaging with government agencies to secure contracts for the development and production of rocket systems for both commercial and defense applications. These partnerships will provide access to funding and support, enabling the factory to pursue ambitious projects.

Challenges and Opportunities

The Augsburg Rocket Factory faces both challenges and opportunities in the coming years. The competitive landscape is becoming increasingly crowded, with new entrants emerging and established players investing heavily in research and development. Technological advancements are rapidly transforming the aerospace industry, requiring the factory to constantly adapt and innovate.

- Competition:The factory faces competition from both domestic and international companies, including established players like SpaceX, Blue Origin, and Arianespace. To stay ahead, the Augsburg Rocket Factory must focus on developing innovative technologies and building strong partnerships.

- Technological Advancements:The rapid pace of technological advancements in the aerospace industry presents both opportunities and challenges. The factory must invest in research and development to stay ahead of the curve and adopt new technologies to improve its products and processes.

- Regulatory Environment:The regulatory environment for the aerospace industry is constantly evolving, with new regulations and safety standards being implemented. The Augsburg Rocket Factory must comply with these regulations and ensure its products meet the highest safety standards.

Projected Growth Trajectory

The Augsburg Rocket Factory’s projected growth trajectory over the next 5-10 years is depicted in the following visual representation:

[Image of a line graph showing the projected growth of the Augsburg Rocket Factory over the next 5-10 years. The graph should include data on funding, production capacity, and workforce size. The x-axis should represent time, and the y-axis should represent the corresponding values. The graph should show a steady upward trend, indicating significant growth in all areas.]

The graph illustrates the Augsburg Rocket Factory’s ambitious growth plans, with significant increases in funding, production capacity, and workforce size. The factory is expected to become a major player in the global aerospace industry, contributing to the advancement of space exploration and technological innovation.