Europe us head to head 3d printing innovation surge – Europe vs. US: A 3D Printing Innovation Surge – It’s a race to the future, a clash of titans in the realm of additive manufacturing. Both continents are witnessing a dramatic upswing in 3D printing innovation, each fueled by unique strengths and ambitions.

From cutting-edge research to groundbreaking applications, the competition is fierce, pushing the boundaries of what’s possible with this transformative technology.

This blog post will dive into the heart of this technological rivalry, exploring the key drivers, trends, and innovations shaping the 3D printing landscape in Europe and the US. We’ll compare and contrast the approaches, strengths, and weaknesses of each region, analyzing the potential impact on industries, economies, and society as a whole.

The 3D Printing Landscape in Europe and the US: Europe Us Head To Head 3d Printing Innovation Surge

The global 3D printing industry is experiencing a rapid surge, with Europe and the US leading the charge. Both regions boast a vibrant ecosystem of innovators, manufacturers, and researchers pushing the boundaries of this transformative technology. Understanding the unique characteristics of each region is crucial for comprehending the future of 3D printing.

Adoption and Development

The adoption and development of 3D printing in Europe and the US vary significantly. While both regions have seen a surge in adoption, the US generally leads in terms of overall market size and investment. The US boasts a strong manufacturing base and a culture of innovation, contributing to the rapid adoption of 3D printing across various sectors.

Europe, on the other hand, has a more fragmented market, with varying levels of adoption across different countries. However, Europe is rapidly catching up, particularly in sectors like healthcare, aerospace, and automotive, where 3D printing is increasingly seen as a key enabler for innovation and competitiveness.

Key Players and Industry Leaders

Both Europe and the US have a diverse range of key players and industry leaders driving 3D printing innovation.

US

- Stratasys:A leading provider of fused deposition modeling (FDM) and polyjet 3D printing systems, serving a wide range of industries.

- 3D Systems:A pioneer in 3D printing technology, offering a comprehensive portfolio of products and services, including stereolithography (SLA) and selective laser sintering (SLS) systems.

- HP:A major player in the 3D printing space, known for its multi-jet fusion (MJF) technology, which offers high-speed and high-quality production capabilities.

- GE Additive:A subsidiary of General Electric, focusing on industrial-scale 3D printing solutions for aerospace, energy, and healthcare industries.

- Desktop Metal:A leading provider of metal 3D printing systems, offering cost-effective and scalable solutions for manufacturing.

Europe

- EOS:A German company specializing in industrial-grade powder bed fusion (PBF) systems, serving industries like aerospace, automotive, and medical.

- Materialise:A Belgian company providing software and services for 3D printing, specializing in medical applications and customized solutions.

- Arcam AB:A Swedish company known for its electron beam melting (EBM) technology, used for producing high-performance metal parts.

- Renishaw:A British company specializing in additive manufacturing systems and metrology solutions, serving a wide range of industries.

- SLM Solutions:A German company offering selective laser melting (SLM) systems for producing high-quality metal parts.

Regulatory Landscape and Government Initiatives

The regulatory landscape and government initiatives surrounding 3D printing differ significantly between Europe and the US.

US

- The US Food and Drug Administration (FDA):The FDA plays a crucial role in regulating medical devices, including those produced using 3D printing. The FDA has established guidelines and regulations for 3D printed medical devices to ensure safety and efficacy.

- The National Institute of Standards and Technology (NIST):NIST plays a key role in promoting 3D printing innovation and developing standards for the industry. NIST has established frameworks for 3D printing quality assurance and measurement.

- The National Aeronautics and Space Administration (NASA):NASA has been a strong advocate for 3D printing, using it for various space exploration projects. NASA has also funded research and development initiatives related to 3D printing.

Europe

- The European Union (EU):The EU has implemented several initiatives to promote 3D printing, including funding programs and research projects. The EU is also working on developing harmonized standards for 3D printing.

- The European Medicines Agency (EMA):The EMA is responsible for regulating medicines and medical devices in Europe. The EMA has issued guidelines for the use of 3D printing in the pharmaceutical industry.

- National initiatives:Several European countries have implemented national initiatives to promote 3D printing, including Germany’s “Industry 4.0” strategy and the UK’s “Made Smarter” program.

Innovation Drivers and Trends

The surge in 3D printing innovation in both Europe and the US is driven by a confluence of factors, including technological advancements, increasing demand across various industries, and supportive government policies. This section delves into the key drivers and emerging trends shaping the future of 3D printing in both regions.

Technological Advancements

Technological advancements are at the forefront of the 3D printing revolution, driving innovation and expanding its capabilities. This includes advancements in materials, printing processes, and software, leading to higher resolution, faster printing speeds, and wider material selection.

- Additive Manufacturing:Additive manufacturing, or 3D printing, involves building objects layer by layer from a digital design, offering greater design freedom and enabling the creation of complex geometries. This has revolutionized manufacturing processes, enabling the production of customized and personalized products.

- Bioprinting:Bioprinting uses 3D printing techniques to create living tissues and organs, paving the way for personalized medicine, regenerative therapies, and drug testing. This technology is being explored for applications in organ transplantation, tissue engineering, and drug discovery.

- 4D Printing:4D printing goes beyond traditional 3D printing by incorporating materials that can change shape and properties in response to external stimuli, such as temperature or light. This enables the creation of self-assembling structures and objects that can adapt to their environment, opening up new possibilities in fields like architecture, robotics, and wearable technology.

Browse the implementation of greek ai startup acquired by japanese automation giant in real-world situations to understand its applications.

Industry 4.0 and the Internet of Things

Industry 4.0, characterized by the integration of digital technologies in manufacturing, is profoundly impacting 3D printing innovation. The Internet of Things (IoT) plays a crucial role, connecting 3D printers to networks, enabling real-time monitoring, data analysis, and remote control.

- Data Analytics:The integration of IoT and data analytics allows manufacturers to optimize printing processes, track material usage, and identify potential issues in real-time. This leads to increased efficiency, reduced waste, and improved product quality.

- Remote Monitoring and Control:Remote monitoring and control capabilities enable manufacturers to monitor and manage 3D printers from anywhere in the world, allowing for better resource allocation and streamlined operations.

- Collaborative Manufacturing:The interconnected nature of Industry 4.0 fosters collaboration among manufacturers, designers, and engineers, accelerating the development and deployment of new 3D printing technologies and applications.

Government Initiatives and Funding

Government initiatives and funding play a crucial role in fostering 3D printing innovation. Both Europe and the US have implemented programs to support research, development, and adoption of 3D printing technologies.

- European Union’s Horizon Europe Program:The EU’s Horizon Europe program allocates significant funding for research and innovation projects related to 3D printing, including advancements in materials, processes, and applications.

- US National Institute of Standards and Technology (NIST):NIST conducts research and provides guidance on 3D printing standards and best practices, supporting the development and adoption of reliable and interoperable 3D printing technologies.

Emerging Applications, Europe us head to head 3d printing innovation surge

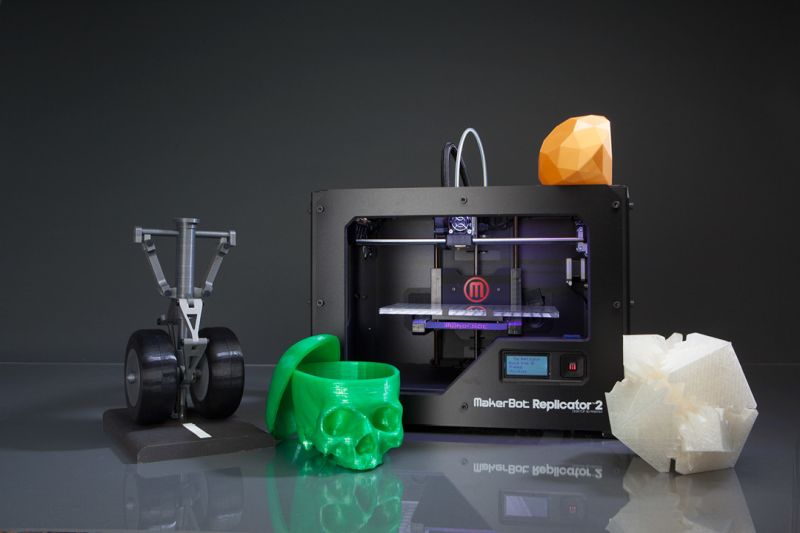

The applications of 3D printing are expanding rapidly, driving innovation in diverse sectors. From healthcare and aerospace to consumer goods and education, 3D printing is revolutionizing how products are designed, manufactured, and used.

- Healthcare:3D printing is transforming healthcare, enabling the creation of customized medical devices, implants, and prosthetics. It also plays a vital role in personalized medicine, drug delivery, and tissue engineering.

- Aerospace:3D printing is being used to manufacture lightweight and complex components for aircraft and spacecraft, reducing production time and costs. This technology is also being explored for space exploration and satellite construction.

- Consumer Goods:3D printing is making its way into the consumer market, enabling the production of customized goods, personalized accessories, and on-demand manufacturing. This is driving innovation in areas like fashion, footwear, and home decor.

- Education:3D printing is increasingly being used in education, providing students with hands-on learning experiences in STEM fields. It enables the creation of prototypes, models, and educational tools, fostering creativity and innovation.

Head-to-Head Comparison of Key Innovations

The European Union and the United States have both been active in advancing 3D printing technology, resulting in a landscape of innovations that cater to various sectors. This section delves into a comparative analysis of key innovations, highlighting their strengths and weaknesses and exploring their potential impact on diverse industries.

Metal 3D Printing

Metal 3D printing, also known as additive manufacturing, is a transformative technology with the potential to revolutionize manufacturing processes. Both the EU and the US have made significant strides in this area, with each region developing distinct innovations.

- Europe:The EU has been at the forefront of developing innovative metal 3D printing technologies, particularly in the field of laser powder bed fusion (LPBF). A notable example is the work of the Fraunhofer Institute for Laser Technology (ILT) in Germany, which has pioneered the use of LPBF for producing high-performance metal components in various industries, including aerospace, automotive, and medical devices.

The EU has also invested heavily in research and development of new metal alloys specifically tailored for 3D printing, which has opened up possibilities for creating parts with enhanced properties like strength, durability, and heat resistance.

- United States:The US has made significant contributions to metal 3D printing through advancements in directed energy deposition (DED) technology. DED involves using a high-energy beam to melt and deposit metal powder onto a substrate, creating complex geometries layer by layer. Companies like GE Additive (formerly known as Concept Laser) and SLM Solutions in the US have been instrumental in developing DED systems for large-scale metal 3D printing, particularly in the aerospace and energy sectors.

- Advantages of LPBF:LPBF offers high precision and detailed resolution, allowing for the creation of intricate designs and complex geometries. This makes it suitable for applications requiring high accuracy and intricate details, such as medical implants and aerospace components.

- Advantages of DED:DED is known for its high deposition rates, enabling the rapid production of large-scale metal parts. This makes it ideal for applications requiring high throughput, such as the fabrication of large molds or tooling components.

- Disadvantages of LPBF:LPBF systems can be expensive to purchase and operate, limiting their accessibility for small and medium-sized enterprises (SMEs). The process also requires skilled operators and specialized post-processing techniques, adding to the overall cost.

- Disadvantages of DED:DED typically produces parts with lower surface finish quality compared to LPBF, requiring additional post-processing steps to achieve desired surface smoothness. The process can also be prone to defects like porosity and cracks, necessitating stringent quality control measures.

- Impact on Industries:Metal 3D printing innovations are poised to revolutionize various industries, including:

- Aerospace:LPBF and DED enable the production of lightweight and highly durable aerospace components, reducing fuel consumption and improving aircraft performance.

- Automotive:Metal 3D printing allows for the creation of customized and complex automotive parts, leading to improved vehicle performance and fuel efficiency.

- Medical Devices:LPBF enables the fabrication of intricate and customized medical implants, offering better patient outcomes and personalized treatment options.

Economic and Social Implications

The rise of 3D printing technology is not just a technological advancement but a catalyst for profound economic and social changes. This innovation has the potential to reshape industries, create new job opportunities, and redefine consumer behavior. Understanding the economic and social implications of 3D printing is crucial for both Europe and the United States as they navigate this rapidly evolving landscape.

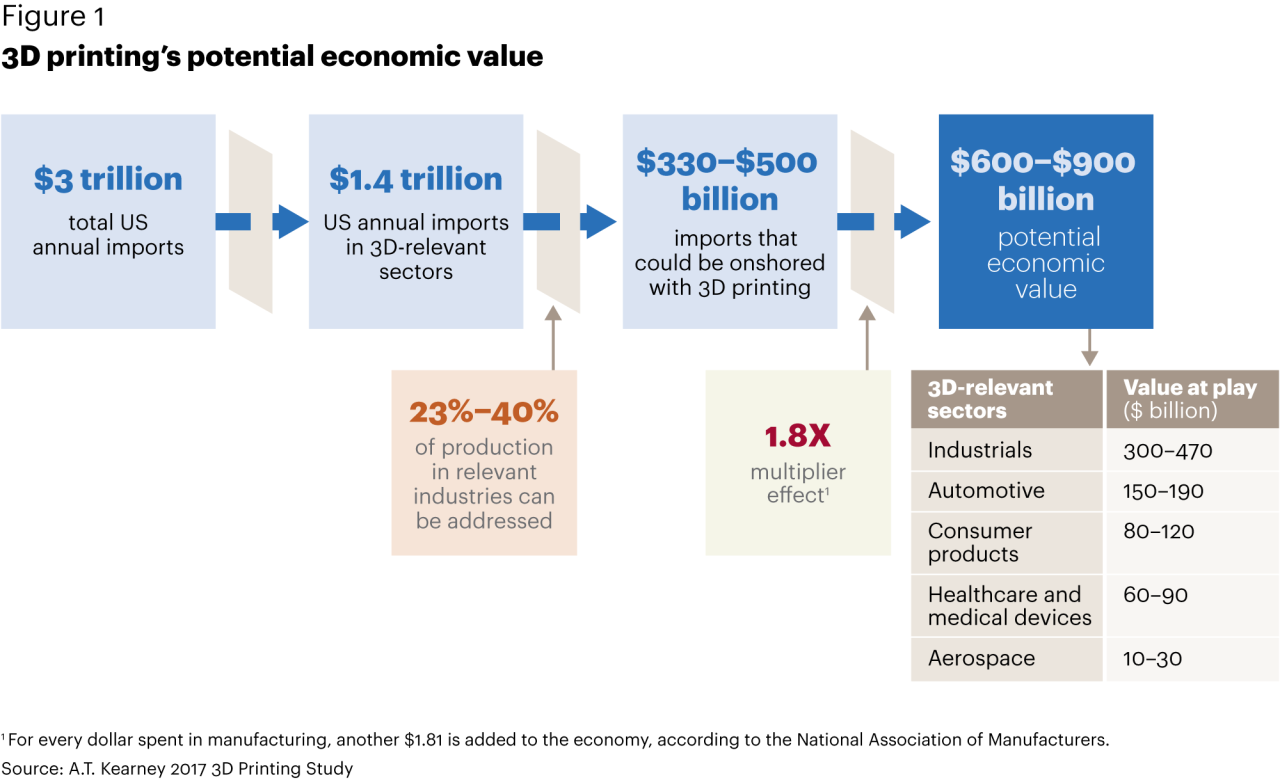

Economic Impact

The economic impact of 3D printing is multifaceted and far-reaching. It’s not just about replacing traditional manufacturing processes but about creating new industries and business models.

Job Creation and Investment

D printing is creating new job opportunities in various sectors, including:

- Design and Engineering:3D printing requires skilled professionals who can design and optimize products for additive manufacturing.

- Manufacturing and Production:3D printing is driving the demand for technicians and operators who can manage and maintain 3D printing equipment.

- Research and Development:The continuous innovation in 3D printing technology necessitates researchers and developers to push the boundaries of this field.

- Materials Science:3D printing is driving the development of new materials and processes, creating opportunities for materials scientists and engineers.

Beyond job creation, 3D printing is attracting significant investment in research, development, and commercialization. This investment is fueling the growth of 3D printing companies and driving innovation in the sector.

Trade and Globalization

D printing is disrupting traditional trade patterns. It enables companies to manufacture products locally, reducing reliance on global supply chains and potentially leading to reshoring of manufacturing. This localized production can reduce transportation costs and lead times, benefiting both businesses and consumers.

Social Implications

D printing’s social implications are wide-ranging, impacting how we design, manufacture, and consume products.

Impact on Manufacturing

D printing is transforming manufacturing by:

- Mass Customization:3D printing allows manufacturers to personalize products to meet specific customer needs, leading to a shift from mass production to mass customization.

- Decentralized Manufacturing:3D printing enables distributed manufacturing, bringing production closer to consumers and reducing the need for large-scale factories.

- Rapid Prototyping:3D printing facilitates rapid prototyping, allowing manufacturers to test and iterate designs quickly and efficiently.

These changes are leading to a more agile and responsive manufacturing sector.

Impact on Design

D printing is empowering designers by:

- Design Freedom:3D printing allows designers to create complex geometries and intricate designs that would be impossible with traditional manufacturing methods.

- Rapid Iteration:3D printing enables designers to quickly iterate on designs, testing different prototypes and exploring new possibilities.

- New Materials and Processes:3D printing opens up opportunities for designers to experiment with new materials and processes, leading to innovative product designs.

These advancements are pushing the boundaries of design and innovation.

Impact on Consumer Behavior

D printing is changing how consumers interact with products by:

- DIY and Customization:3D printing allows consumers to create their own products, leading to a rise in DIY culture and personalized consumption.

- Access to Unique Products:3D printing enables consumers to access unique and niche products that might not be available through traditional retail channels.

- Sustainable Consumption:3D printing can promote sustainable consumption by reducing waste and enabling the production of on-demand products, minimizing the need for large-scale inventory.

These shifts in consumer behavior are leading to a more empowered and customized consumer experience.

Ethical Considerations

While 3D printing presents significant opportunities, it also raises ethical considerations that need careful attention.

Intellectual Property

The ease of replicating designs using 3D printing raises concerns about intellectual property protection. There are concerns about counterfeiting and unauthorized copying of designs.

“The potential for unauthorized copying and distribution of designs is a significant concern, particularly in industries where intellectual property is highly valuable.”

Job Displacement

The automation potential of 3D printing raises concerns about job displacement in traditional manufacturing industries. While new jobs are being created in 3D printing related fields, there is a need to ensure that workers are adequately trained and supported in the transition.

“It’s essential to implement policies that mitigate job displacement and promote retraining and reskilling initiatives to ensure a smooth transition for workers affected by automation.”

Environmental Impact

While 3D printing can promote sustainable consumption, it’s crucial to address the environmental impact of the technology itself. The production and disposal of 3D printing materials and the energy consumption of 3D printers need careful consideration.

“It’s important to develop sustainable materials and processes for 3D printing and to promote responsible disposal of printed objects to minimize the environmental footprint of this technology.”

Future Outlook and Predictions

The 3D printing landscape in Europe and the US is poised for continued growth and transformation. Looking ahead, both regions are expected to witness significant advancements in technology, applications, and market adoption. This section delves into the future direction of 3D printing innovation, exploring potential collaborations and challenges that lie ahead.

Potential for Collaboration and Knowledge Sharing

Collaboration and knowledge sharing between Europe and the US can accelerate the pace of innovation and foster a more robust 3D printing ecosystem. This can be achieved through:

- Joint research initiatives:Collaborative research projects involving universities, research institutions, and industry players from both regions can lead to breakthroughs in materials science, software development, and manufacturing processes.

- Knowledge exchange programs:Regular workshops, conferences, and exchange programs can facilitate the sharing of best practices, research findings, and technical expertise between experts from Europe and the US.

- Industry partnerships:Strategic partnerships between companies in both regions can foster cross-border innovation and accelerate the adoption of 3D printing technologies in various sectors.

Challenges and Opportunities

While the future of 3D printing holds immense potential, several challenges and opportunities need to be addressed:

- Scaling up production:Meeting the increasing demand for 3D-printed products requires scaling up production processes, which necessitates advancements in automation, robotics, and manufacturing infrastructure.

- Material development:Developing new materials with enhanced properties, such as strength, durability, and biocompatibility, is crucial for expanding the applications of 3D printing.

- Skills gap:The rapid growth of the 3D printing industry requires a skilled workforce with expertise in design, manufacturing, and operation. Bridging the skills gap through education and training programs is essential.

- Regulatory frameworks:Clear and consistent regulatory frameworks are needed to address safety concerns, intellectual property rights, and environmental sustainability related to 3D printing.