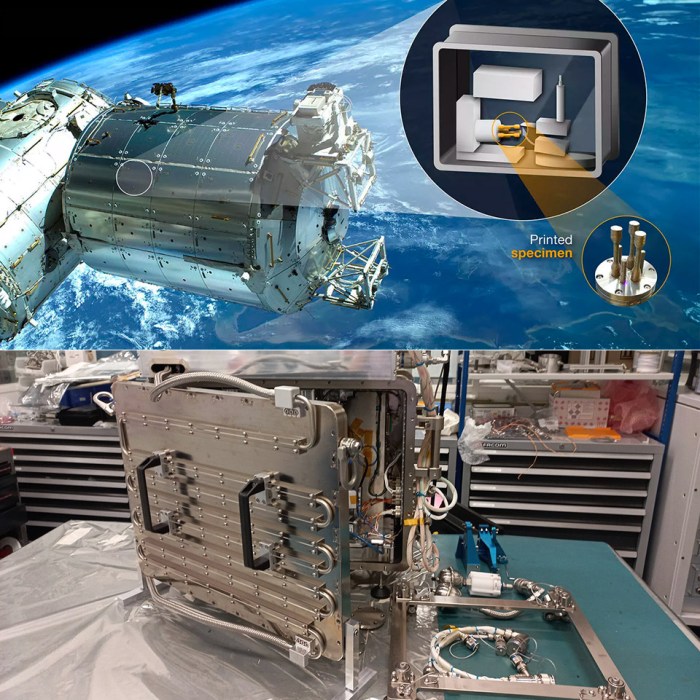

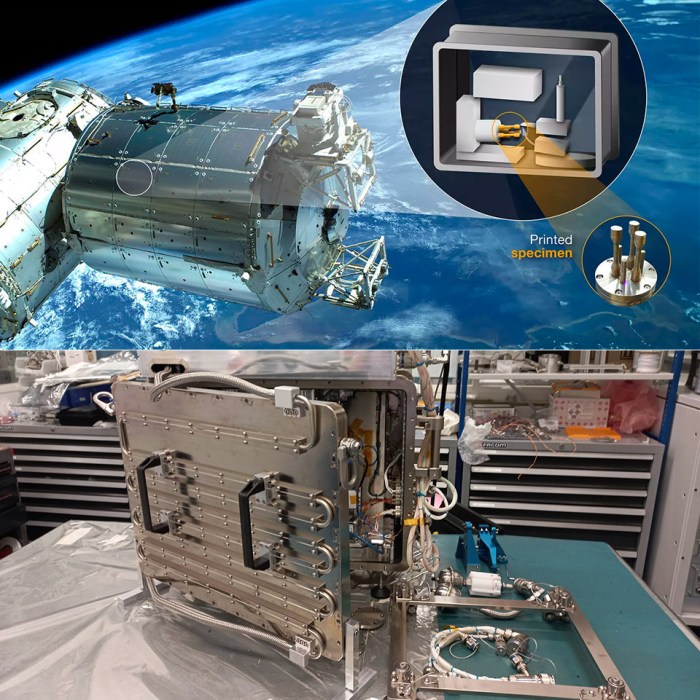

Esa worlds first metal 3d printer space iss – ESA’s first metal 3D printer in space, installed on the International Space Station (ISS), marks a groundbreaking moment in space exploration. This technological feat paves the way for a future where on-demand manufacturing becomes a reality, revolutionizing how we build and maintain structures in the harsh environment of space.

Imagine a future where astronauts can print tools, spare parts, and even components for habitats directly on the ISS, eliminating the need for bulky and expensive shipments from Earth. This is the promise of ESA’s groundbreaking 3D printer, a testament to the power of innovation and the relentless pursuit of pushing boundaries in space exploration.

ESA’s Metal 3D Printing Breakthrough

ESA’s recent deployment of a metal 3D printer to the International Space Station (ISS) marks a groundbreaking moment in space exploration. This is the first time a metal 3D printer has been successfully operated in space, opening up new possibilities for on-demand manufacturing and future space missions.

Technological Advancements

This remarkable achievement is a testament to the significant advancements in 3D printing technology. The printer, developed by Made In Space, is a modified version of their existing 3D printer, designed specifically for the harsh environment of space. The key advancements include:

- Zero-gravity operation:The printer has been meticulously engineered to operate in microgravity, overcoming the challenges of material deposition and part adhesion in a weightless environment.

- Closed-loop system:The printer utilizes a closed-loop system for material handling and processing, ensuring the safety and efficiency of the printing process.

- Robust design:The printer’s design incorporates robust materials and components that can withstand the extreme temperatures, vibrations, and radiation found in space.

Comparison with Traditional Manufacturing Methods

Traditionally, manufacturing in space has relied on pre-fabricated components shipped from Earth, a process that is expensive, time-consuming, and limited in scope. The metal 3D printer offers several advantages over these traditional methods:

- On-demand manufacturing:The printer enables astronauts to manufacture parts and tools as needed, eliminating the need for extensive pre-planning and long lead times for deliveries from Earth.

- Reduced reliance on Earth-based supply chains:By allowing for the production of critical components in space, the printer reduces dependence on Earth-based supply chains, making space missions more self-sufficient and resilient.

- Greater design flexibility:3D printing offers greater design flexibility compared to traditional methods, allowing for the creation of complex geometries and intricate parts that would be impossible to manufacture using conventional techniques.

The International Space Station (ISS) as a Testbed

The International Space Station (ISS) is not just a marvel of engineering; it serves as a unique and crucial testbed for technologies that could revolutionize space exploration and even life on Earth. One such technology is metal 3D printing, which has the potential to transform how we build and maintain structures in space.

Challenges of 3D Printing in Microgravity

The microgravity environment of the ISS presents unique challenges for 3D printing. The lack of gravity affects the behavior of materials, particularly molten metal, during the printing process.

- Material Flow and Deposition:In microgravity, molten metal behaves differently than it does on Earth. Its flow and deposition patterns can be unpredictable, potentially affecting the quality and structural integrity of the printed object.

- Support Structures:The absence of gravity eliminates the need for traditional support structures used in terrestrial 3D printing. However, new strategies for supporting the printed object during the process are needed.

- Heat Dissipation:Heat dissipation is crucial for successful metal 3D printing. In the confined environment of the ISS, managing heat generated during the printing process can be challenging.

Rationale for Choosing the ISS

The ISS offers a perfect environment to test and refine metal 3D printing technology due to its:

- Microgravity Environment:The ISS provides a unique and challenging environment to test how metal 3D printing performs in microgravity.

- Long-Duration Missions:The ISS provides a platform for long-duration experiments, allowing scientists to observe the long-term effects of microgravity on printed objects.

- Access to Expertise:The ISS is home to a diverse group of astronauts and scientists with expertise in materials science, engineering, and space operations.

Potential Applications of Metal 3D Printing on the ISS

Metal 3D printing holds immense potential for the ISS and future space missions. Its applications range from:

- On-Demand Manufacturing:The ability to print parts and tools as needed eliminates the need for bulky and expensive spare parts inventory, making missions more efficient and resilient.

- Repair and Maintenance:Metal 3D printing can be used to repair damaged equipment or create custom tools for maintenance tasks, enabling astronauts to address issues in-situ.

- Construction:Metal 3D printing could be used to build structures, such as habitats or research modules, in space, potentially revolutionizing space construction.

- Scientific Experiments:Metal 3D printing can be used to create specialized components for scientific experiments on the ISS, allowing for greater flexibility and customization.

Implications for Future Space Exploration: Esa Worlds First Metal 3d Printer Space Iss

The successful deployment of a metal 3D printer on the International Space Station (ISS) marks a significant leap forward in space exploration, paving the way for unprecedented advancements in future missions. This groundbreaking technology holds the potential to revolutionize how we design, build, and maintain spacecraft and infrastructure in the vast expanse of space.

On-Demand Manufacturing

The ability to manufacture components and tools on-demand in space will drastically reduce the reliance on pre-packaged supplies, which are currently transported from Earth at great expense and risk. This capability will be invaluable for extended missions, such as lunar and Martian exploration, where resupply missions are infrequent and costly.

On-demand manufacturing in space can reduce reliance on pre-packaged supplies, saving significant resources and allowing for greater flexibility in mission operations.

- Reduced Launch Mass:By eliminating the need to transport every tool and component from Earth, on-demand manufacturing significantly reduces launch mass, allowing for the inclusion of more scientific instruments, crew supplies, or fuel on spacecraft. For example, the Mars Science Laboratory mission, which landed the Curiosity rover on Mars, had to launch with a significant amount of extra weight to accommodate the rover’s components.

Obtain recommendations related to dependence clouds eu startup growth new approach that can assist you today.

If metal 3D printing had been available, some of these components could have been manufactured in space, resulting in a lighter and more efficient launch.

- Enhanced Mission Flexibility:On-demand manufacturing provides astronauts with the ability to adapt to unforeseen circumstances and create solutions to unexpected problems in real-time. This flexibility is crucial for long-duration missions, where unforeseen challenges are likely to arise. For instance, if a critical component on a spacecraft malfunctions, astronauts could use a 3D printer to create a replacement part, avoiding mission delays or even failure.

- Increased Sustainability:On-demand manufacturing allows for the recycling of materials in space, reducing the need to transport new materials from Earth. This approach promotes sustainability in space exploration, minimizing the environmental impact of our activities beyond Earth.

Scenario: A Metal 3D Printed Space Habitat

Imagine a future space habitat on the Moon, where astronauts are conducting research and exploring the lunar surface. Using a metal 3D printer, the crew can fabricate specialized tools and equipment, such as:

- Custom-fit tools:The crew can print tools specifically designed for lunar exploration, such as specialized drills, scoops, and probes, optimizing their performance and efficiency.

- Structural components:The printer can be used to create modular structures, expanding the habitat as needed, and providing shelter for astronauts during lunar excursions.

- Repair and maintenance:If a component of the habitat malfunctions, the crew can use the 3D printer to create a replacement part, minimizing downtime and ensuring continued operation.

- Scientific instruments:Astronauts can print specialized scientific instruments, allowing them to adapt their research based on new discoveries and changing priorities.

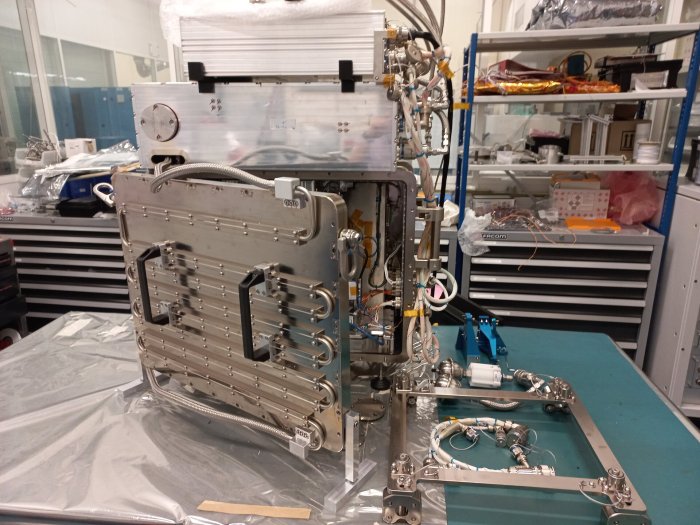

Technical Aspects of the Metal 3D Printer

The metal 3D printer deployed to the International Space Station represents a significant leap in additive manufacturing technology, enabling the production of complex metal parts in a microgravity environment. This technology has the potential to revolutionize space exploration, enabling on-demand fabrication of critical components for missions, reducing reliance on Earth-based supply chains.

Metal Alloys Used for 3D Printing

The metal 3D printer on the ISS utilizes a powder-bed fusion process, where a laser melts and fuses layers of metal powder to create a 3D object. The specific metal alloys that can be printed using this technology are carefully selected for their properties and suitability for space applications.

The printer is capable of printing various alloys, including:

- Titanium alloys: Known for their high strength-to-weight ratio, corrosion resistance, and biocompatibility, making them suitable for structural components, medical implants, and aerospace applications.

- Stainless steel alloys: Offer excellent durability, corrosion resistance, and machinability, making them suitable for a wide range of applications, including tools, fixtures, and structural components.

- Nickel alloys: Possess high strength, resistance to extreme temperatures and corrosion, making them suitable for high-performance applications in aerospace, energy, and chemical industries.

- Aluminum alloys: Known for their lightweight, high strength, and good conductivity, making them suitable for aerospace components, automotive parts, and electronics.

Advantages and Disadvantages of Metal 3D Printing

Metal 3D printing offers several advantages over traditional manufacturing methods:

| Advantages | Disadvantages |

|---|---|

| Greater design freedom, allowing for complex geometries and intricate designs | Limited part size and complexity, depending on the printer’s capabilities |

| Reduced lead times and prototyping costs, enabling rapid iteration and design optimization | Lower production rates compared to traditional manufacturing methods, making it suitable for small-scale production |

| On-demand fabrication, eliminating the need for large inventories and reducing supply chain reliance | Potential for surface roughness and internal porosity, requiring post-processing steps for certain applications |

| Material efficiency, reducing waste and minimizing environmental impact | Higher initial investment costs for equipment and materials compared to traditional manufacturing |

Working Principle of the Metal 3D Printer, Esa worlds first metal 3d printer space iss

The metal 3D printer on the ISS utilizes a powder-bed fusion process. Here’s a simplified diagram illustrating the working principle:

[Image: A diagram depicting the metal 3D printer’s working principle. The diagram shows a powder bed, a laser, and a build platform. The laser melts and fuses layers of metal powder on the build platform, creating a 3D object layer by layer.]

- Powder Bed: A thin layer of metal powder is spread evenly across a build platform. This powder serves as the material source for the 3D object.

- Laser: A high-powered laser beam is directed onto the powder bed, melting and fusing the powder particles together. The laser’s path is controlled by a computer, following the design specifications of the 3D object.

- Build Platform: The build platform is lowered by a precise distance after each layer is fused, allowing the next layer of powder to be deposited and fused on top of the previous layer.

- Support Structures: In some cases, support structures may be printed along with the main object to provide stability during the printing process. These structures are typically removed after printing.

The Role of ESA in Space Technology Development

The European Space Agency (ESA) has been a key player in space exploration for over six decades, contributing significantly to advancements in technology, science, and international collaboration. The agency’s commitment to innovation is evident in its diverse portfolio of missions and projects, ranging from Earth observation and navigation to deep space exploration and human spaceflight.

The recent achievement of 3D printing metal in space on the International Space Station is a testament to ESA’s dedication to pushing the boundaries of space technology.

ESA’s Contributions to Space Exploration

ESA’s history is marked by numerous groundbreaking contributions to space exploration. Here are some notable examples:

- The Ariane rocket family: ESA’s Ariane launch vehicles have become a cornerstone of the commercial launch market, enabling the deployment of numerous satellites and spacecraft into orbit. Ariane 5, the latest iteration of the Ariane family, is known for its reliability and performance, launching satellites for both European and international clients.

- The Hubble Space Telescope: While not solely an ESA project, the agency played a critical role in the development and deployment of the Hubble Space Telescope, a revolutionary observatory that has transformed our understanding of the universe. ESA provided key components for the telescope and continues to contribute to its scientific operations.

- The International Space Station (ISS): ESA has been a founding member of the ISS partnership, contributing modules, scientific experiments, and astronauts to the project. The agency’s contributions have been crucial to the success of the ISS as a platform for scientific research and technological development.

- The Rosetta mission: ESA’s Rosetta mission achieved a historic feat by successfully landing a probe on a comet, providing unprecedented insights into the origins of our solar system. The mission showcased ESA’s expertise in deep space navigation, spacecraft engineering, and scientific instrumentation.

- The ExoMars mission: ESA is leading the ExoMars mission, a joint venture with Roscosmos, aimed at searching for signs of past or present life on Mars. The mission involves sending a rover and a surface platform to the red planet, demonstrating ESA’s commitment to exploring the potential for life beyond Earth.

Alignment with ESA’s Strategic Goals

The 3D printing achievement aligns perfectly with ESA’s strategic goals, which include:

- Promoting innovation and technological advancement: The development of a metal 3D printer for space applications showcases ESA’s commitment to pushing the boundaries of technology and exploring new possibilities for space exploration.

- Enabling sustainable and long-duration space missions: 3D printing in space offers the potential for on-demand manufacturing, reducing the need for costly and complex logistics chains. This capability is essential for enabling long-duration missions to the Moon, Mars, and beyond.

- Strengthening international collaboration: The 3D printing project is a collaborative effort involving ESA, NASA, and commercial partners, demonstrating the importance of international partnerships for advancing space exploration.

Future Plans for Utilizing 3D Printing in Space

ESA has ambitious plans for utilizing 3D printing in future space missions. These plans include:

- Developing more advanced 3D printing technologies: ESA is actively investing in research and development to improve the capabilities of 3D printing in space, focusing on enhancing printing speed, accuracy, and material versatility.

- Expanding the range of printable materials: The agency aims to expand the range of materials that can be printed in space, including advanced alloys, composites, and ceramics, to meet the specific needs of future missions.

- Exploring the potential for on-demand manufacturing of spacecraft components: ESA envisions a future where 3D printing is used to manufacture critical spacecraft components in orbit, reducing reliance on ground-based production and enabling in-space repairs and upgrades.

- Developing 3D printing applications for lunar and Martian bases: ESA is investigating the use of 3D printing to construct habitats, infrastructure, and tools for future lunar and Martian bases, leveraging the technology’s potential for resource utilization and sustainable development.