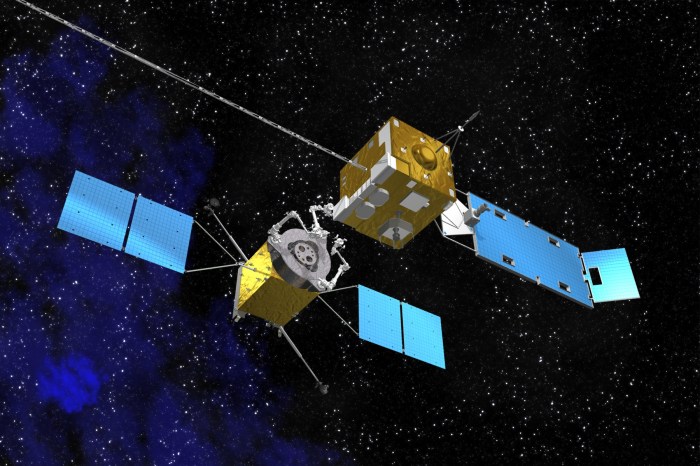

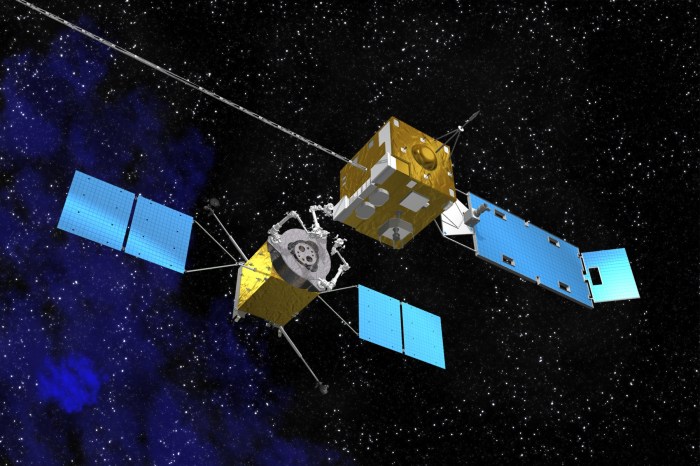

ClearSpace in orbit refuelling service spacecraft satellites – a groundbreaking concept aimed at addressing the growing problem of space debris. As our reliance on satellites continues to escalate, so too does the risk of collisions and orbital clutter. This, in turn, threatens the functionality of vital space assets.

Enter the innovative solution of in-orbit refueling, a technological marvel that could revolutionize the way we manage our celestial infrastructure.

Imagine a fleet of specialized spacecraft designed to extend the lifespan of satellites by replenishing their fuel reserves. This revolutionary approach not only mitigates the need for frequent satellite replacements but also significantly reduces the accumulation of defunct spacecraft in Earth’s orbit.

It’s a game-changer for sustainable space exploration and a testament to humanity’s ingenuity in tackling complex challenges.

Space Debris and Orbital Clutter

The Earth’s orbit is becoming increasingly congested, posing a significant threat to operational satellites and future space exploration. This growing problem, known as space debris, comprises a multitude of objects, ranging from defunct satellites and rocket stages to smaller fragments resulting from collisions or explosions.

Impact of Space Debris

Space debris poses a significant risk to operational satellites, as collisions can cause damage or even destroy them. This has far-reaching consequences, disrupting critical services such as communication, navigation, and weather forecasting. The International Space Station (ISS), for example, has had to perform several maneuvers to avoid collisions with debris.

Role of In-Space Refueling in Mitigating Orbital Clutter

In-space refueling plays a crucial role in mitigating orbital clutter by extending the lifespan of satellites. Instead of discarding a satellite at the end of its operational life, refueling allows it to remain in orbit for a longer duration, reducing the need for replacements.

This not only minimizes the number of defunct satellites in orbit but also helps preserve valuable orbital slots.

Examples of Refueling’s Impact on Satellite Lifespan

- The Hubble Space Telescope, a vital instrument for astronomical observation, has been refueled several times, extending its operational life and enabling groundbreaking discoveries.

- The International Space Station (ISS) is regularly refueled, allowing it to maintain its operations and serve as a platform for scientific research.

Refueling Technologies and Methods: Clearspace In Orbit Refuelling Service Spacecraft Satellites

Refueling satellites in orbit is a critical aspect of extending their operational lifespan and ensuring the continued functionality of vital space infrastructure. Various methods have been developed to facilitate this process, each with its own advantages and disadvantages.

Robotic Arms, Clearspace in orbit refuelling service spacecraft satellites

Robotic arms are a common method for refueling satellites. These arms, typically equipped with specialized grippers, can maneuver to connect with the satellite’s fuel tank and transfer fuel from a dedicated refueling spacecraft.

- Advantages:Robotic arms offer flexibility and precision, allowing for accurate fuel transfer. They can be adapted to different satellite designs and are relatively cost-effective.

- Disadvantages:Robotic arms are limited in their reach and require a certain degree of proximity to the satellite. They are also susceptible to damage from space debris or micrometeoroids.

Docking Systems

Docking systems involve the physical connection of a refueling spacecraft to the target satellite. This creates a secure and direct pathway for fuel transfer.

- Advantages:Docking systems enable high-volume fuel transfer and are well-suited for larger satellites. They provide a stable connection, minimizing the risk of fuel spills.

- Disadvantages:Docking systems are complex and require precise maneuvering and alignment. They are also more expensive to develop and implement compared to robotic arms.

Specialized Transfer Mechanisms

Specialized transfer mechanisms, such as fuel bladders or hoses, can be used to transfer fuel between spacecraft. These mechanisms are designed to be lightweight and compact, making them suitable for smaller satellites.

Learn about more about the process of moon made solar station transmit power space to earth in the field.

- Advantages:Specialized transfer mechanisms are relatively inexpensive and can be easily integrated into existing spacecraft designs. They offer a flexible and adaptable approach to refueling.

- Disadvantages:Specialized transfer mechanisms may have limited fuel transfer capacity and require careful handling to avoid leaks or spills.

Challenges of In-Space Refueling

Refueling satellites in the harsh environment of space presents unique challenges.

- Microgravity:The absence of gravity requires special considerations for fuel transfer. Fuel must be carefully controlled to prevent it from floating away or sloshing around in the tanks.

- Extreme Temperature Variations:Satellites experience significant temperature fluctuations in orbit, which can affect the properties of fuel and the performance of refueling systems.

- Space Debris:The presence of space debris poses a risk to refueling operations. Collisions with debris can damage refueling equipment or compromise the integrity of the fuel transfer process.

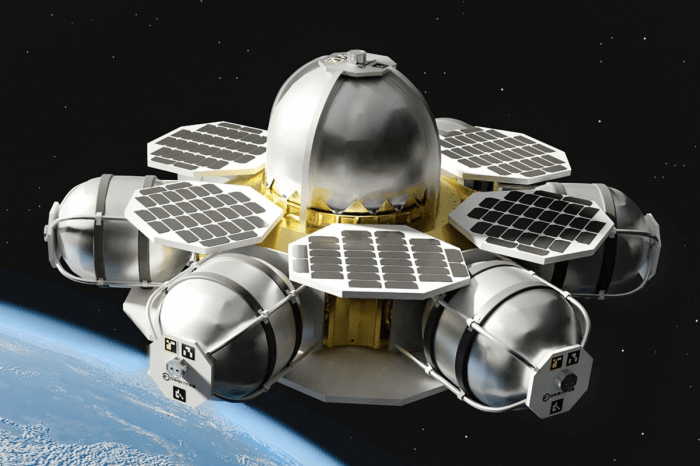

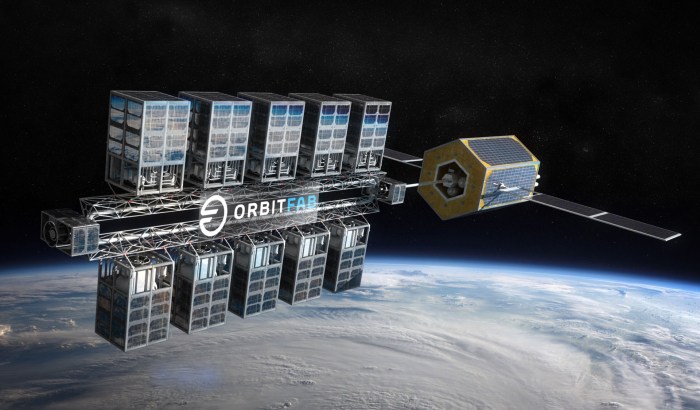

Refueling Service Spacecraft

The concept of a dedicated refueling service spacecraft is a critical component of the future of space exploration and the sustainability of space operations. These specialized spacecraft are designed to extend the lifespan of existing satellites and space assets by providing them with the necessary fuel to continue their missions.

This eliminates the need to launch new satellites, reducing launch costs and space debris.

Fuel Storage Capacity

Fuel storage capacity is a key consideration in designing a refueling service spacecraft. The capacity must be sufficient to accommodate the needs of the target satellite and the duration of the refueling mission. The type of fuel used, whether it’s liquid hydrogen, kerosene, or other propellants, will influence the storage design and the necessary insulation and pressure requirements.

Propulsion Systems

The propulsion system of a refueling service spacecraft needs to be efficient and reliable to maneuver and dock with the target satellite. The choice of propulsion system depends on the specific mission requirements, including the mass of the spacecraft, the distance to the target, and the desired thrust levels.

Electric propulsion systems, known for their efficiency and long-term operation, are often considered for this purpose.

Docking Mechanisms

A robust docking mechanism is essential for safe and secure refueling operations. The docking mechanism must be compatible with the target satellite’s docking port and capable of maintaining a stable connection during the refueling process. It should also be equipped with sensors and actuators to monitor the docking process and ensure proper alignment.

Safety Protocols and Procedures

Refueling operations in space are inherently complex and require strict safety protocols and procedures to prevent accidents or contamination.

- Pre-Docking Inspections:Before approaching the target satellite, a thorough inspection is conducted to assess its condition and identify any potential hazards. This includes checking for leaks, debris, or other anomalies that could compromise the refueling operation.

- Docking Procedures:The docking process is carefully planned and executed, with multiple safety checks and redundancies in place. The docking mechanism is designed to ensure a secure and leak-proof connection between the two spacecraft.

- Fuel Transfer Procedures:Fuel transfer is conducted under strict control, with monitoring systems in place to track fuel flow, pressure, and temperature. This ensures that the fuel is transferred safely and efficiently without exceeding the target satellite’s fuel tank capacity.

- Post-Refueling Inspections:After the refueling operation is complete, a thorough inspection is conducted to verify the success of the transfer and identify any potential issues. This includes checking for leaks, contamination, or other problems that could affect the target satellite’s performance.

Economic and Operational Considerations

The economic feasibility and operational aspects of in-space refueling services are crucial factors in determining their viability and future success. Assessing the costs, revenue streams, and return on investment is essential for attracting investors and establishing a sustainable business model.

Additionally, overcoming operational challenges related to establishing a reliable and efficient refueling network in orbit is paramount for the long-term success of this emerging industry.

Economic Feasibility

Analyzing the economic feasibility of in-space refueling services involves evaluating the costs associated with developing, launching, and operating refueling spacecraft, as well as the potential revenue streams and return on investment. The cost of developing and launching a refueling spacecraft can be substantial, ranging from hundreds of millions to billions of dollars depending on the size, complexity, and technology employed.

Recurring operational costs include fuel production and transportation, maintenance, and crew or automation expenses. Potential revenue streams for in-space refueling services can be derived from charging satellite operators for refueling services, extending the operational life of valuable assets, and potentially offering fuel to other spacecraft in need.

The return on investment is highly dependent on the frequency of refueling missions, the cost of services, and the lifespan extension achieved.

Operational Challenges

Establishing a reliable and efficient refueling network in orbit presents several operational challenges.

- Precise Docking and Rendezvous:Refueling spacecraft need to rendezvous and dock with target satellites with extreme precision to ensure a safe and successful transfer of fuel.

- Fuel Storage and Transfer:Developing and implementing safe and efficient methods for storing and transferring cryogenic fuels in the harsh space environment is crucial.

- Space Debris Mitigation:The potential for collisions with space debris is a significant concern for refueling spacecraft and their target satellites.

- International Regulations:Navigating international regulations and agreements related to space operations and activities is essential for ensuring legal compliance.

Business Models and Partnerships

Several business models and partnerships can be explored for developing and operating in-space refueling services.

- Direct Service Provider:A company can act as a direct service provider, offering refueling services to satellite operators on a contractual basis.

- Joint Ventures:Collaborations with satellite manufacturers, launch providers, or other space companies can create synergies and reduce development costs.

- Government Partnerships:Government agencies may provide funding, infrastructure, or regulatory support for in-space refueling initiatives.

Future Prospects and Applications

In-space refueling goes beyond merely extending the lifespan of existing satellites. It opens up a new realm of possibilities for space exploration, scientific research, and the development of a robust space-based infrastructure. This technology has the potential to revolutionize how we utilize space, enabling ambitious missions that were previously unimaginable.

Potential Applications for In-Space Refueling

In-space refueling can be instrumental in supporting a wide range of space endeavors, extending beyond simply prolonging satellite lifespans.

- Enabling Long-Duration Missions:Refueling allows spacecraft to remain operational for extended periods, facilitating missions to distant destinations like Mars or the outer solar system. This is crucial for scientific exploration, as it enables continuous observation and data collection over years, potentially leading to groundbreaking discoveries.

- Supporting Space-Based Infrastructure:Refueling is essential for the long-term viability of space-based infrastructure, such as space stations, lunar outposts, and even potential future space-based manufacturing facilities. It ensures the continuous operation of these vital assets, allowing for their expansion and development.

- Enhancing Scientific Research:Refueling enables the deployment of scientific instruments in high-Earth orbits or beyond, where they can operate for extended durations, collecting valuable data on phenomena like solar activity, cosmic rays, and the evolution of stars and galaxies. This extended operational time allows for more comprehensive data collection and analysis.

- Facilitating Space Tourism:In-space refueling can support the growth of space tourism by enabling the development of reusable spacecraft for multiple trips, making space travel more affordable and accessible to a wider audience. This could lead to a new era of space exploration, where individuals can experience the wonders of space firsthand.

Benefits and Challenges of In-Space Refueling

In-space refueling offers a range of benefits, but it also presents significant challenges that need to be addressed for its successful implementation.