Fibre optics answer to water loss leaky pipes – Fibre Optics: The Answer to Water Loss from Leaky Pipes. Imagine a world where leaky pipes are a thing of the past. With the advent of fibre optic technology, this vision is becoming a reality. This innovative solution offers a precise and efficient way to detect leaks, allowing for proactive maintenance and preventing costly water loss.

Leaky pipes are a major problem, both environmentally and economically. They can lead to wasted water, increased water bills, and even damage to property. Traditional methods for detecting and repairing leaks are often disruptive, time-consuming, and expensive. Fibre optics, however, offer a more efficient and cost-effective solution.

By using light pulses to monitor pipe conditions, fibre optic sensors can detect leaks with remarkable accuracy and speed.

The Problem of Water Loss Through Leaky Pipes: Fibre Optics Answer To Water Loss Leaky Pipes

Leaky pipes are a silent and often overlooked problem that can have significant economic and environmental consequences. They represent a major source of water waste, leading to increased water bills and contributing to water scarcity.

The Economic Impact of Leaky Pipes

Leaky pipes can lead to significant financial losses for homeowners and businesses. The constant dripping of water can result in higher water bills, and in severe cases, can lead to water damage and mold growth, requiring expensive repairs.

- According to the EPA, the average household can lose up to 10,000 gallons of water per year due to leaks.

- A slow drip from a faucet can waste up to 3,000 gallons of water per year.

- A leaky toilet can waste up to 200 gallons of water per day.

The Environmental Impact of Leaky Pipes

The environmental impact of leaky pipes is significant, contributing to water scarcity and energy consumption.

- Water is a precious resource, and wasting it through leaks puts a strain on our water supply, especially in areas experiencing drought.

- The energy used to treat and transport water is wasted when it leaks from pipes, contributing to greenhouse gas emissions.

- Leaking pipes can also lead to the contamination of groundwater, posing a threat to human health and the environment.

Common Causes of Leaky Pipes

Leaky pipes can be caused by a variety of factors, including age, corrosion, and improper installation.

- Age:Pipes made of materials like copper, galvanized steel, and cast iron can deteriorate over time, becoming more prone to leaks. The average lifespan of copper pipes is around 50 years, while galvanized steel pipes can last up to 70 years.

Cast iron pipes can last even longer, but are susceptible to corrosion and cracking.

- Corrosion:Corrosion is a major cause of leaks in older pipes. This occurs when water reacts with the metal, causing it to rust and weaken.

- Improper Installation:Improper installation of pipes can also lead to leaks.

This could include using the wrong type of pipe, not using the correct fittings, or not securing the pipes properly.

Traditional Methods for Detecting and Repairing Leaky Pipes

For many years, traditional methods have been the go-to approach for identifying and fixing leaky pipes. These methods rely on a combination of experience, observation, and sometimes, invasive techniques.

Traditional Leak Detection Methods

Traditional leak detection methods involve using our senses and simple tools to pinpoint the source of a leak. These methods often require some knowledge of plumbing systems and can be time-consuming.

- Listening for Leaks:This involves carefully listening for the sound of running water, dripping, or hissing, which can indicate a leak. A stethoscope can be used to amplify the sound and pinpoint the location more accurately.

- Dye Tracing:This method involves introducing a dye into the water system and then observing where the dye appears. If the dye emerges at a specific location, it indicates a leak in that area.

- Pressure Testing:This method involves pressurizing the water system and then monitoring for pressure drops. A significant pressure drop can indicate a leak, and the location of the drop can help pinpoint the leak’s source.

Traditional Leak Repair Methods

Traditional leak repair methods typically involve physically accessing the leaky pipe and making the necessary repairs. These methods often require excavation and can be disruptive and costly.

- Excavation:This involves digging up the ground to expose the leaky pipe. This method is often necessary for leaks in underground pipes, but it can be time-consuming and disruptive.

- Pipe Replacement:This involves removing the damaged section of pipe and replacing it with a new one. This method is effective for leaks caused by corrosion, cracks, or other damage to the pipe.

- Sealing:This involves using specialized materials to seal leaks in pipes. This method can be used for minor leaks or leaks in hard-to-reach areas.

Limitations of Traditional Leak Detection and Repair Methods, Fibre optics answer to water loss leaky pipes

Traditional methods for leak detection and repair have several limitations.

- Disruption:Traditional methods can be disruptive, requiring excavation, pipe replacement, or other invasive procedures that can affect surrounding areas.

- Cost:Traditional methods can be costly, especially if they require extensive excavation or pipe replacement.

- Time-consuming:Traditional methods can be time-consuming, especially if the leak is difficult to locate or access.

Fibre Optics

Fibre optic technology, commonly used in high-speed internet connections, has found a novel application in leak detection. This innovative approach offers a reliable and efficient method for identifying leaks in various types of pipes, from water mains to industrial pipelines.

How Fibre Optics Detect Leaks

Fibre optic sensors are embedded within or alongside the pipe, forming a network that monitors changes in pressure, temperature, or vibrations. When a leak occurs, it disrupts the surrounding environment, causing subtle changes in these parameters. These changes are detected by the fibre optic sensors and transmitted to a central monitoring system, alerting operators to the presence of a leak.

Advantages of Fibre Optic Leak Detection

- Accuracy:Fibre optic sensors provide highly accurate leak detection, enabling early identification of leaks before they escalate into significant problems.

- Non-invasive Nature:The installation of fibre optic sensors is typically non-invasive, minimizing disruption to existing infrastructure.

- Real-time Monitoring:Fibre optic systems offer real-time leak detection, allowing for immediate response and prevention of further damage.

Successful Applications of Fibre Optic Leak Detection

Fibre optic leak detection has been successfully implemented in diverse settings, including:

- Water Distribution Networks:Municipalities are increasingly adopting fibre optic systems to monitor their water distribution networks, ensuring timely leak detection and minimizing water loss.

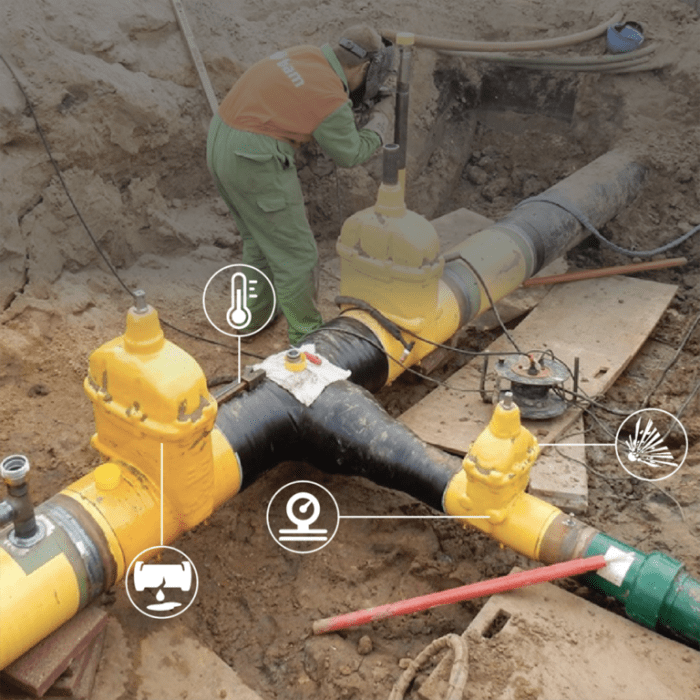

- Industrial Pipelines:Fibre optics are used to detect leaks in pipelines carrying hazardous materials, preventing environmental contamination and safety hazards.

- Underground Infrastructure:Fibre optic sensors are deployed to monitor underground infrastructure, such as sewer lines and gas pipelines, enabling early leak detection and preventing costly repairs.

How Fibre Optics Work for Leak Detection

Fibre optic leak detection technology leverages the unique properties of light travelling through optical fibres to detect leaks in various systems. It offers a sensitive and reliable method for identifying leaks, surpassing traditional methods in accuracy and efficiency.

Principles of Fibre Optic Sensing

Fibre optic sensors work by measuring changes in the light travelling through the optical fibre. These changes can be caused by various factors, including pressure, temperature, and vibration, which are often associated with leaks.

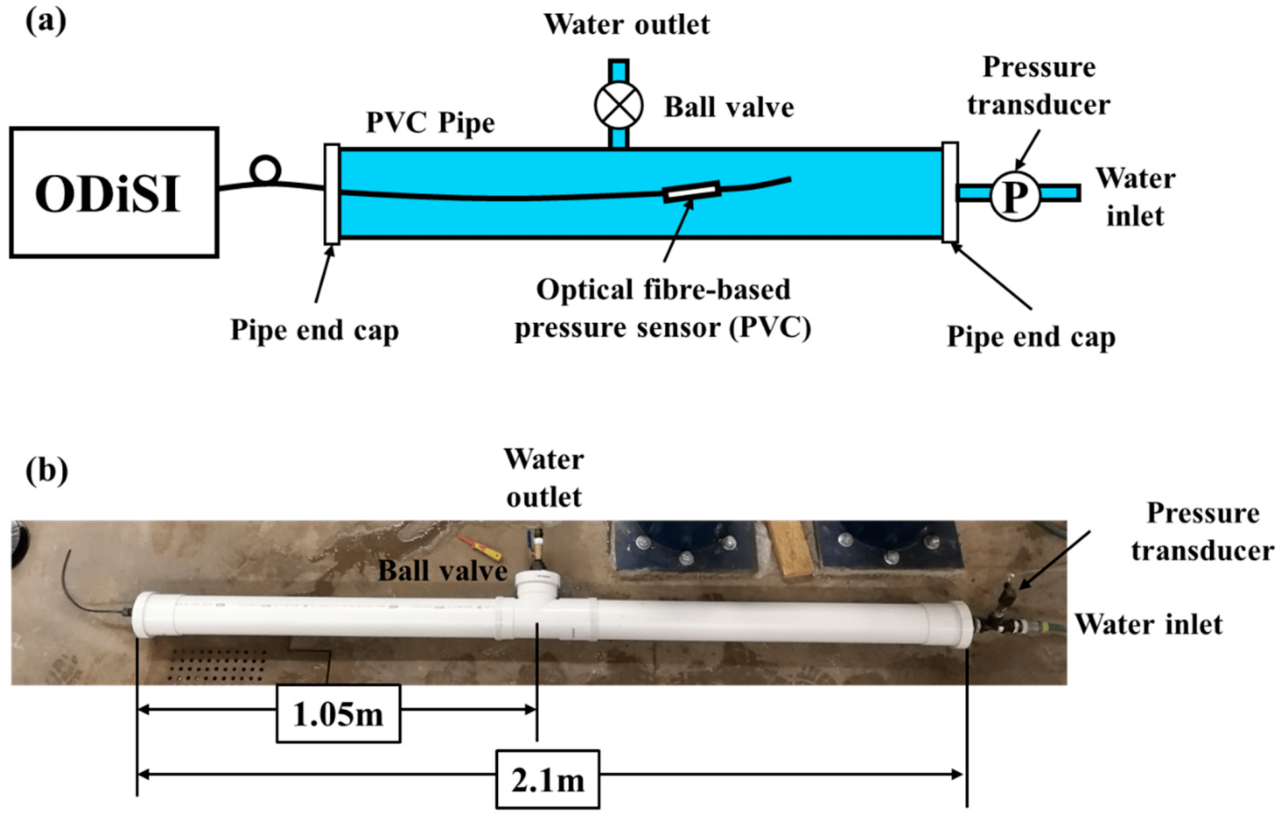

- Pressure Sensing:Fibre optic pressure sensors detect changes in pressure by measuring the strain on the optical fibre. When a leak occurs, the pressure in the surrounding environment changes, causing the fibre to stretch or compress. This strain alters the speed of light travelling through the fibre, which is detected by the sensor.

- Temperature Sensing:Fibre optic temperature sensors measure changes in temperature by detecting the wavelength of light emitted by the fibre. Leaks can cause a change in temperature, either through the release of hot or cold water or due to the presence of moisture.

The sensor detects these temperature variations by measuring the wavelength of light emitted by the fibre.

- Vibration Sensing:Fibre optic vibration sensors detect changes in vibration by measuring the frequency of light pulses travelling through the fibre. Leaks can cause vibrations in the surrounding environment, which are detected by the sensor as changes in the frequency of the light pulses.

Types of Fibre Optic Sensors for Leak Detection

Various types of fibre optic sensors are available for leak detection, each designed for specific applications.

- Distributed Temperature Sensing (DTS):DTS uses a single optical fibre to measure temperature along its entire length. This allows for continuous monitoring of large areas, making it ideal for detecting leaks in pipelines, water mains, and other extended infrastructure.

- Distributed Acoustic Sensing (DAS):DAS uses a single optical fibre to detect vibrations along its entire length. This makes it suitable for detecting leaks in pipelines, underground cables, and other infrastructure where vibrations can indicate a leak.

- Point Sensors:Point sensors are designed to measure specific parameters at a single point, such as pressure or temperature. These sensors are typically used in areas where a leak is suspected or where precise monitoring is required.

Installation and Configuration of a Fibre Optic Leak Detection System

Installing and configuring a fibre optic leak detection system involves several steps.

- System Design:The first step is to design the system based on the specific application and the area to be monitored. This includes determining the type of sensors, the number of sensors required, and the layout of the fibre optic network.

- Fibre Optic Cable Installation:The next step is to install the fibre optic cable along the area to be monitored. The cable should be routed along the pipeline, water main, or other infrastructure where leaks are likely to occur.

- Sensor Installation:Sensors are then installed at strategic locations along the fibre optic cable. The location of the sensors should be chosen based on the potential leak points and the desired level of monitoring.

- System Calibration:Once the sensors are installed, the system must be calibrated to ensure accurate readings. This involves establishing a baseline for the sensor readings under normal operating conditions.

- Data Acquisition and Analysis:The system continuously monitors the sensor readings and sends the data to a central monitoring station. The data is then analyzed to identify any changes that indicate a leak.

Benefits of Fibre Optics for Water Loss Management

Fibre optic leak detection offers significant advantages over traditional methods, making it a valuable tool for water loss management. By providing accurate and timely leak detection, fibre optics can contribute to cost savings, reduced water consumption, and environmental sustainability.

You also can investigate more thoroughly about netflix minus 1 million users spain no password sharing policy to enhance your awareness in the field of netflix minus 1 million users spain no password sharing policy.

Cost-Effectiveness of Fibre Optic Leak Detection

Fibre optic leak detection systems offer a cost-effective approach to managing water loss compared to traditional methods.

- Reduced Repair Costs:Early leak detection with fibre optics helps prevent minor leaks from escalating into major pipe bursts, reducing costly repairs and replacements.

- Minimized Water Waste:By pinpointing leak locations precisely, fibre optics minimize the amount of water wasted, leading to lower water bills and reduced water treatment costs.

- Long-Term Savings:The initial investment in a fibre optic system can be recouped quickly through reduced repair costs and water bills, resulting in long-term savings.

Reducing Water Consumption and Saving on Water Bills

Fibre optic leak detection plays a crucial role in reducing water consumption and saving money on water bills.

- Early Leak Detection:Fibre optics detect leaks at their initial stages, preventing significant water loss and minimizing the impact on water bills.

- Targeted Repairs:Precise leak localization allows for targeted repairs, ensuring that only the affected sections of the pipe are repaired, saving time and resources.

- Water Conservation:By reducing water loss, fibre optics contribute to overall water conservation efforts, leading to lower water consumption and reduced water bills.

Environmental Sustainability Through Water Waste Minimization

Fibre optic leak detection aligns with environmental sustainability goals by minimizing water waste.

- Preservation of Water Resources:By reducing water loss, fibre optics help conserve precious water resources, contributing to sustainable water management practices.

- Reduced Energy Consumption:Minimizing water waste reduces the energy required for water treatment and distribution, promoting energy efficiency.

- Environmental Protection:By preventing leaks and reducing water waste, fibre optics contribute to protecting the environment from the negative impacts of water pollution and depletion.

Case Studies and Real-World Applications

The effectiveness of fibre optic leak detection systems is evident in numerous real-world projects across various industries. These case studies showcase the tangible benefits of adopting this technology for water loss management, highlighting its impact on reducing water waste and improving infrastructure efficiency.

Water Distribution Networks

The use of fibre optics has proven highly effective in detecting leaks in water distribution networks, leading to significant reductions in water loss and improved operational efficiency. One notable case study involved the implementation of a fibre optic leak detection system in a large urban water distribution network in the United Kingdom.

The system, deployed along critical pipelines, successfully identified numerous leaks that were previously undetected by traditional methods. This resulted in a substantial decrease in water loss, estimated at over 20%, leading to cost savings for the water utility and a reduction in environmental impact.

Future Trends and Developments in Fibre Optic Leak Detection

The field of fibre optic leak detection is constantly evolving, driven by the need for more efficient, reliable, and cost-effective solutions for water loss management. Emerging technologies and advancements in fibre optic sensing are paving the way for a new era of leak detection capabilities.

Advancements in Fibre Optic Sensing

The development of advanced fibre optic sensing technologies is at the forefront of improving leak detection capabilities. These advancements focus on enhancing sensitivity, accuracy, and the ability to detect leaks in challenging environments.

- Distributed Acoustic Sensing (DAS):DAS technology utilizes the principle of backscattered light to detect vibrations along the fibre optic cable. This allows for the detection of leaks by identifying the specific location of water hammer or other disturbances caused by leaking pipes. The use of DAS has significantly improved the accuracy and sensitivity of leak detection, enabling the identification of leaks in a wider range of pipe materials and sizes.

- Distributed Temperature Sensing (DTS):DTS technology measures temperature variations along the fibre optic cable. Leaks can be detected by identifying temperature anomalies caused by the release of cold water from a leaking pipe. DTS systems are particularly effective in detecting leaks in underground pipes, where other methods may be less reliable.

- Fibre Bragg Grating (FBG) Sensors:FBG sensors are embedded within the fibre optic cable and act as tiny reflectors that respond to changes in strain or temperature. This technology allows for the precise location of leaks by measuring the change in the reflected light wavelength.

FBG sensors offer high sensitivity and accuracy, making them ideal for monitoring critical infrastructure, such as water pipelines.

Smart Water Grids and Predictive Maintenance

The integration of fibre optic leak detection systems into smart water grids is revolutionizing water loss management. Smart water grids are interconnected networks that utilize sensors, data analytics, and communication technologies to optimize water distribution and minimize losses.

- Real-Time Leak Detection and Monitoring:Fibre optic sensors provide real-time data on pipe conditions, allowing for immediate detection and response to leaks. This proactive approach helps prevent significant water loss and minimize the impact of leaks on water supply.

- Predictive Maintenance:By analyzing data from fibre optic sensors, utilities can identify potential leak risks before they occur. This predictive maintenance approach allows for timely repairs and reduces the likelihood of major pipe failures, leading to significant cost savings and improved water infrastructure reliability.

Role of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are playing an increasingly important role in enhancing fibre optic leak detection systems. These technologies can analyze vast amounts of data from fibre optic sensors, identify patterns, and predict potential leaks with greater accuracy.

- Leak Detection Algorithm Optimization:AI and ML algorithms can be trained to identify specific leak signatures and differentiate them from other noise or disturbances. This optimization leads to more accurate and reliable leak detection, reducing the number of false alarms.

- Data Analysis and Interpretation:AI and ML can analyze large datasets from fibre optic sensors, identify trends, and predict future leak events. This predictive capability enables utilities to prioritize repairs and proactively manage water loss.

- Automated Leak Detection and Response:AI and ML can automate the process of leak detection and response, enabling utilities to respond to leaks more efficiently and effectively. This automation reduces the need for human intervention, leading to cost savings and improved response times.