Swiss startup collaborative robots genai humanoid hand – Swiss Startup: Collaborative Robots, GenAI, and Humanoid Hands, is a fascinating combination of cutting-edge technology. This innovative trio is revolutionizing industries and pushing the boundaries of what’s possible in robotics. Switzerland, known for its precision engineering and groundbreaking research, is leading the charge in developing these collaborative robots.

These robots, often called cobots, are designed to work alongside humans, making them ideal for tasks that require dexterity, adaptability, and human-like interaction.

The integration of Generative AI (GenAI) is a game-changer. GenAI enables these robots to learn, adapt, and even generate new solutions, making them incredibly versatile. The development of humanoid hands, capable of mimicking human movements, further enhances their capabilities, allowing them to perform tasks that were previously impossible for robots.

This is a powerful combination, promising to transform industries ranging from manufacturing and healthcare to logistics and beyond.

Swiss Startup Landscape

Switzerland has a thriving startup ecosystem, particularly in the fields of robotics and AI. The country boasts a strong research and development infrastructure, a skilled workforce, and a supportive government environment, making it an attractive location for innovative startups.

Robotics and AI in Switzerland

Switzerland’s commitment to research and development has fostered a vibrant robotics and AI scene. The country is home to world-renowned research institutions like ETH Zurich and EPFL, which are at the forefront of robotics and AI innovation. These institutions produce a steady stream of talented graduates and researchers who contribute to the development of new technologies and startups.

Successful Swiss Robotics Startups

Several Swiss startups have achieved significant success in the robotics field, demonstrating the country’s prowess in this area. Here are a few notable examples:

- Anybotics: This Zurich-based company develops autonomous robots for inspection and data collection in hazardous environments, such as industrial facilities and construction sites. Their flagship product, Anymal, is a quadrupedal robot designed for complex tasks like pipeline inspection and data gathering.

- Clearpath Robotics: Founded in 2009, Clearpath Robotics is a leading provider of autonomous robots for research, education, and industrial applications. Their robots are used in various sectors, including manufacturing, logistics, and agriculture.

- Flyability: This Swiss startup specializes in developing drones for inspection in confined spaces. Their Elios drone is equipped with a collision-resistant design and advanced sensors, making it ideal for inspecting infrastructure, such as power plants and wind turbines, without risking human lives.

Funding Landscape for Swiss Robotics Startups

Switzerland’s startup ecosystem is well-supported by a robust funding landscape. Venture capitalists and angel investors are increasingly interested in investing in robotics and AI startups, recognizing the potential of these technologies to disrupt various industries.

Check what professionals state about podcast boris comes over to co host slack cal henderson and its benefits for the industry.

- Venture Capital Funds: Switzerland has a number of active venture capital funds specializing in deep tech, including robotics and AI. These funds provide significant capital for startups in their early stages of development.

- Government Support: The Swiss government actively supports startups through various initiatives, including grants, tax incentives, and mentorship programs. These programs aim to foster innovation and create a favorable environment for entrepreneurs.

- Incubators and Accelerators: Switzerland boasts a network of incubators and accelerators that provide startups with access to resources, mentorship, and networking opportunities. These programs help startups refine their business models, validate their ideas, and secure funding.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are robots designed to work alongside humans in a shared workspace. They are typically smaller and more agile than traditional industrial robots, and they are equipped with safety features that allow them to operate safely around people.

Cobots are becoming increasingly popular in a wide range of industries, as they offer a number of benefits, including increased productivity, improved safety, and greater flexibility.

Applications of Cobots

Cobots are being used in a variety of industries, including:

- Manufacturing: Cobots are used in a wide range of manufacturing tasks, such as assembly, packaging, welding, and painting. For example, in automotive manufacturing, cobots are used to assist human workers with tasks such as installing parts and performing quality checks.

- Healthcare: Cobots are used in healthcare to assist with tasks such as surgery, rehabilitation, and patient care. For example, cobots can be used to help surgeons perform delicate procedures, or to assist patients with physical therapy exercises.

- Agriculture: Cobots are used in agriculture to assist with tasks such as planting, harvesting, and weeding. For example, cobots can be used to help farmers plant crops more efficiently, or to harvest fruits and vegetables without damaging them.

- Retail: Cobots are used in retail to assist with tasks such as customer service, inventory management, and order fulfillment. For example, cobots can be used to help customers find products, or to stock shelves and prepare orders.

Types of Cobots

Cobots can be classified into different types based on their capabilities and functionalities. Some common types of cobots include:

- Articulated robots:These cobots have multiple joints that allow them to move in a variety of directions. They are typically used for tasks that require a high degree of dexterity, such as assembly and packaging.

- SCARA robots:These cobots have a single arm that can move in a horizontal plane. They are typically used for tasks that require high speed and accuracy, such as pick-and-place operations.

- Delta robots:These cobots have a unique design that allows them to move quickly and efficiently. They are typically used for tasks that require high speed and precision, such as packaging and food handling.

- Cartesian robots:These cobots have a linear motion along three axes. They are typically used for tasks that require a high degree of accuracy, such as pick-and-place operations and dispensing.

Safety Features and Regulations

Cobots are designed to work safely alongside humans, and they are equipped with a number of safety features that help to prevent accidents. These features include:

- Force limiting:Cobots are designed to stop moving if they come into contact with a human. This helps to prevent injuries from collisions.

- Speed and power limiting:Cobots are designed to operate at safe speeds and with limited power. This helps to prevent injuries from being struck by a moving cobot.

- Safety sensors:Cobots are often equipped with sensors that can detect the presence of humans in their workspace. This allows the cobot to slow down or stop moving if a human is nearby.

There are also a number of regulations in place to ensure the safe deployment of cobots. These regulations vary by country, but they typically address issues such as:

- Risk assessment:Employers are required to conduct risk assessments to identify potential hazards associated with the use of cobots.

- Training:Workers who operate cobots must receive adequate training on how to use the robots safely.

- Safety procedures:Employers must establish safety procedures for the use of cobots, including procedures for emergency stops and lockout/tagout.

Generative AI (GenAI)

Generative AI (GenAI) is revolutionizing the field of robotics and automation, enabling the development of more intelligent and adaptable robots. GenAI models can be trained on vast datasets of robotic data, allowing them to learn complex patterns and behaviors. This capability empowers them to generate new robot designs, optimize existing ones, and even control cobots in real-time.

GenAI’s Role in Cobot Design and Optimization, Swiss startup collaborative robots genai humanoid hand

GenAI algorithms can be used to design and optimize cobots, leveraging their ability to learn from data and generate new solutions. For example, GenAI models can be trained on datasets of successful cobot designs, allowing them to identify key features and relationships between design parameters.

This information can then be used to generate novel designs that are optimized for specific tasks or environments.

GenAI for Cobot Control

GenAI can be applied to control cobots in real-time, enabling them to adapt to changing conditions and perform complex tasks. GenAI models can be trained on datasets of robot actions and their corresponding outcomes, allowing them to learn the relationship between actions and results.

This knowledge can be used to generate optimal control strategies for different tasks and environments. For example, a GenAI-powered cobot could learn to adjust its movements in response to unexpected obstacles or changes in the work environment.

GenAI for Cobot Training and Task Adaptation

GenAI can significantly enhance cobot training and task adaptation. By leveraging GenAI, cobots can learn new tasks more efficiently and adapt to changes in their environment with minimal human intervention. GenAI can be used to generate synthetic training data for cobots, enabling them to learn new tasks without the need for extensive real-world training.

For example, a GenAI model could be trained on a dataset of human demonstrations of a specific task, allowing it to generate realistic simulations that can be used to train a cobot.GenAI can also be used to adapt cobots to new tasks or environments.

By analyzing data from previous tasks and environments, GenAI models can identify patterns and relationships that can be used to generalize to new situations. This capability allows cobots to quickly adapt to new tasks and environments, reducing the need for manual reprogramming.

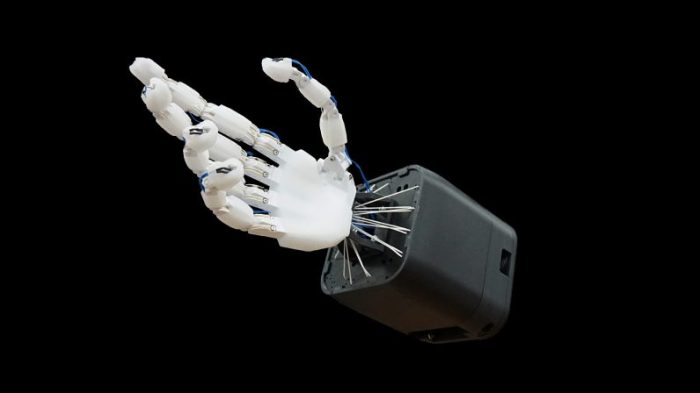

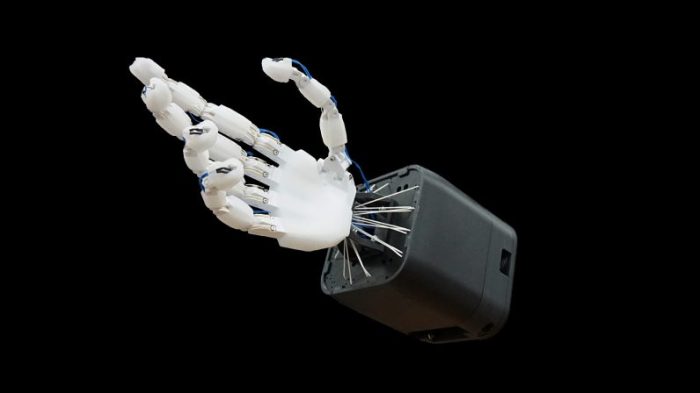

Humanoid Hands

The development of humanoid hands for collaborative robots (cobots) represents a significant step toward creating truly collaborative machines that can seamlessly interact with humans in various tasks. These hands are designed to mimic the dexterity and adaptability of human hands, enabling cobots to perform a wider range of tasks, from delicate assembly operations to complex manipulation of objects.

Integration Challenges and Opportunities

Integrating humanoid hands into cobots presents both challenges and opportunities. One key challenge lies in achieving the required dexterity and precision. Human hands are incredibly complex, with intricate muscle systems and sensory feedback mechanisms that allow for fine motor control and tactile sensing.

Replicating this complexity in a robotic hand is a demanding engineering feat. Additionally, ensuring safety is paramount when integrating such hands into collaborative environments. Cobots equipped with humanoid hands must be able to operate safely alongside humans, preventing accidental collisions or injuries.Despite these challenges, the potential benefits of humanoid hands in cobots are substantial.

They can enhance the capabilities of cobots, enabling them to perform tasks that were previously impossible or highly inefficient. These hands can manipulate delicate objects, operate tools with precision, and even interact with objects in ways that traditional robotic grippers cannot.

Furthermore, the use of humanoid hands can lead to improved human-robot collaboration, as cobots become more adaptable and intuitive to work with.

Humanoid Hand Designs and Capabilities

The following table showcases the functionalities and capabilities of different humanoid hand designs:| Hand Design | Functionality | Capabilities ||—|—|—|| Schunk SDH| 5-fingered, dexterous hand | Capable of grasping and manipulating a wide range of objects, including tools and delicate components.

|| Barrett Hand| 3-fingered, underactuated hand | Designed for tasks requiring high precision and dexterity, such as assembly and manipulation of small objects. || Shadow Robot Hand| 5-fingered, highly dexterous hand | Offers a wide range of movements and can perform complex tasks, such as playing musical instruments or performing surgery.

|| OpenHand Project| 3-fingered, modular hand | Customizable and open-source design, allowing for adaptation to specific tasks and environments. |

The integration of humanoid hands into cobots is a rapidly evolving field, with ongoing research and development efforts focused on improving dexterity, precision, and safety. As these technologies mature, we can expect to see increasingly sophisticated and versatile cobots capable of performing a wide range of tasks alongside humans, leading to significant advancements in automation and collaboration.

Swiss Startup Innovations: Swiss Startup Collaborative Robots Genai Humanoid Hand

Switzerland, renowned for its precision engineering and technological prowess, is a fertile ground for innovative startups pushing the boundaries of robotics and artificial intelligence. In the realm of collaborative robots (cobots), Swiss startups are developing cutting-edge solutions that seamlessly integrate generative AI (GenAI) and humanoid hands, ushering in a new era of human-robot collaboration.

Swiss Startups Leading the Way in Cobot Innovation

The Swiss startup ecosystem is brimming with companies pioneering the development of cobots with GenAI and humanoid hands. These startups are not just building robots; they are crafting intelligent machines that can learn, adapt, and collaborate with humans in a safe and efficient manner.

- Agile Robots: This Zurich-based startup specializes in developing agile cobots with advanced AI capabilities. Their robots are designed to perform tasks that require dexterity and precision, such as assembly, packaging, and handling delicate objects. Agile Robots’ GenAI algorithms enable their cobots to learn from experience and adapt to changing environments, making them ideal for applications where flexibility is paramount.

- Humanoid Robotics: Founded in Lausanne, Humanoid Robotics is at the forefront of developing humanoid hands for cobots. Their hands are equipped with sophisticated sensors and actuators that allow them to grasp and manipulate objects with human-like dexterity. The company’s GenAI algorithms enable their hands to learn new grasping techniques and adapt to different object shapes and sizes, enhancing the versatility of cobots in a wide range of applications.

Case Studies: Real-World Applications of Swiss Cobot Innovations

The innovative cobots developed by Swiss startups are finding their way into various industries, revolutionizing workflows and enhancing productivity.

- Agile Robots in Manufacturing: Agile Robots’ cobots are being deployed in manufacturing facilities to automate tasks such as assembly and packaging. Their AI-powered capabilities enable them to adapt to different product configurations and handle delicate components with precision. This has significantly reduced production time and errors, leading to increased efficiency and cost savings.

- Humanoid Robotics in Healthcare: Humanoid Robotics’ humanoid hands are being used in healthcare settings to assist with tasks such as surgery, rehabilitation, and patient care. Their ability to grasp and manipulate objects with dexterity allows them to perform tasks that are difficult or impossible for human surgeons or caregivers.

The use of humanoid hands in healthcare is expected to improve patient outcomes and enhance the quality of care.

Key Features, Target Markets, and Potential Impact of Swiss Cobot Solutions

| Startup | Key Features | Target Markets | Potential Impact |

|---|---|---|---|

| Agile Robots | Agile cobots with advanced AI capabilities, designed for tasks requiring dexterity and precision. | Manufacturing, logistics, and warehousing. | Increased efficiency, reduced errors, and improved productivity in manufacturing processes. |

| Humanoid Robotics | Humanoid hands with sophisticated sensors and actuators, capable of grasping and manipulating objects with human-like dexterity. | Healthcare, research, and education. | Enhanced surgical precision, improved patient care, and advancements in robotics research. |

Future Trends

The convergence of collaborative robots (cobots), generative AI (GenAI), and humanoid hands is poised to reshape industries and redefine human-machine collaboration. This dynamic trio is set to revolutionize how we work, interact with technology, and navigate the complexities of the future.

The Rise of Advanced Cobots

The future of cobots is characterized by enhanced intelligence, adaptability, and human-like dexterity. Advancements in AI, machine learning, and sensor technology will enable cobots to learn from human interactions, adapt to changing environments, and perform increasingly complex tasks. Cobots will become more collaborative, seamlessly integrating into human workflows and offering real-time assistance.

The Power of GenAI in Robotics

Generative AI will play a pivotal role in enhancing the capabilities of cobots and humanoid hands. GenAI algorithms will empower robots to generate new designs, optimize workflows, and even anticipate human needs. For instance, GenAI can be used to create personalized training programs for cobots, ensuring they are optimally trained for specific tasks.

Humanoid Hands: Bridging the Gap

Humanoid hands are crucial for enabling robots to perform tasks that require fine motor skills and dexterity. The future of humanoid hands will see advancements in tactile sensing, grip control, and object manipulation. This will allow robots to handle delicate objects, perform intricate tasks, and collaborate more effectively with humans.

Applications Across Industries

The combined power of cobots, GenAI, and humanoid hands will have far-reaching applications across industries:

- Manufacturing:Cobots equipped with GenAI and humanoid hands can automate assembly lines, perform quality inspections, and assist in complex manufacturing processes. For example, a GenAI-powered cobot could be used to design and manufacture custom-made products, leveraging real-time data and user preferences.

- Healthcare:Robots with humanoid hands and AI capabilities can assist surgeons in delicate procedures, provide personalized care to patients, and perform tasks that require precision and dexterity. GenAI can be used to analyze medical images and provide diagnostic insights.

- Construction:Cobots with advanced capabilities can be used to build structures, perform repetitive tasks, and ensure worker safety. GenAI can be used to optimize construction plans and manage logistics.

- Retail:Robots with humanoid hands can assist customers, stock shelves, and perform other tasks in retail settings. GenAI can be used to analyze customer data and personalize shopping experiences.