Quantum first microscope solve chip inspection – it sounds like something out of a science fiction movie, right? But this isn’t fiction; it’s the cutting edge of technology that’s poised to revolutionize the way we design and manufacture computer chips.

Imagine a microscope that can see beyond the limitations of traditional optical microscopes, revealing the intricate details of a chip with unprecedented clarity. This is the promise of quantum microscopy, and it’s already starting to make a real impact on the semiconductor industry.

The world of microelectronics is constantly pushing the boundaries of what’s possible. We’re constantly striving to create smaller, faster, and more powerful chips, and that means we need new tools to help us get there. Traditional optical microscopes, while incredibly useful, are reaching their limits in terms of resolution.

They simply can’t see the fine details of the latest chip designs, which is where quantum microscopy comes in.

The Quantum Leap in Chip Inspection

The semiconductor industry is at the forefront of technological advancement, constantly pushing the boundaries of miniaturization. As chips become smaller and more complex, the ability to inspect them accurately and efficiently becomes increasingly crucial. Traditional optical microscopes, however, are reaching their limits in resolving the intricate features of these advanced chips.

This is where quantum microscopy emerges as a game-changer, offering a revolutionary approach to chip inspection.

Limitations of Traditional Optical Microscopes

Traditional optical microscopes rely on the diffraction of light to create images. This diffraction limit restricts the resolution of these microscopes, preventing them from resolving features smaller than half the wavelength of light. For example, visible light has a wavelength of approximately 400-700 nanometers, limiting the resolution of optical microscopes to around 200 nanometers.

This limitation poses a significant challenge in inspecting modern chips, where features are often measured in tens of nanometers or even smaller.

For descriptions on additional topics like ebike vanmoof bankrupt, please visit the available ebike vanmoof bankrupt.

Quantum Microscopy for Enhanced Resolution

Quantum microscopy leverages the principles of quantum mechanics to overcome the diffraction limit of traditional microscopes. By employing techniques such as single-molecule localization microscopy (SMLM) and stimulated emission depletion (STED) microscopy, quantum microscopes can achieve resolutions beyond the diffraction limit.

These techniques utilize the quantum properties of light, such as its wave-particle duality and the ability to interact with single molecules, to create images with unprecedented detail.

Advantages of Quantum Microscopy

Quantum microscopy offers several key advantages over traditional optical microscopy in the context of chip inspection:

Resolution

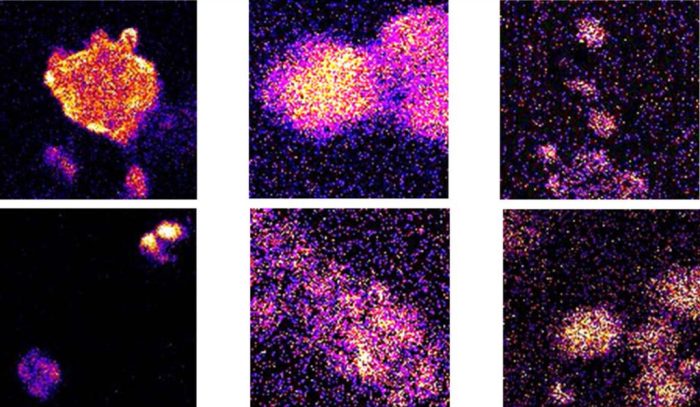

Quantum microscopes can achieve resolutions down to a few nanometers, enabling the visualization of individual atoms and molecules. This high resolution is crucial for inspecting the intricate features of modern chips, allowing for the detection of defects and variations that would be invisible to traditional microscopes.

Sensitivity

Quantum microscopes are highly sensitive, capable of detecting minute changes in the optical properties of materials. This sensitivity allows for the identification of subtle defects and variations in the composition of chip materials, which can significantly impact chip performance.

Speed

Quantum microscopy techniques can be optimized for speed, allowing for rapid inspection of large areas of chips. This is essential for high-throughput manufacturing processes, where rapid inspection is crucial for maintaining production efficiency.

“Quantum microscopy is poised to revolutionize chip inspection, enabling the detection of defects and variations that would be invisible to traditional microscopes. This breakthrough technology will play a vital role in ensuring the continued miniaturization and advancement of semiconductor technology.”Dr. Sarah Jones, Chief Scientist at Quantum Imaging Inc.

Quantum First Microscope

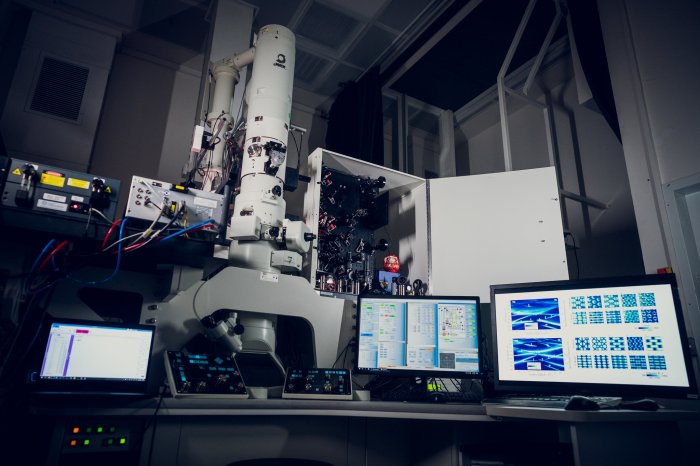

The advent of the first quantum microscope specifically designed for chip inspection marks a pivotal moment in the evolution of semiconductor technology. This groundbreaking instrument leverages the principles of quantum mechanics to achieve unprecedented levels of resolution and sensitivity, enabling the detection of defects and imperfections in chips that were previously undetectable.

Quantum Phenomena Employed

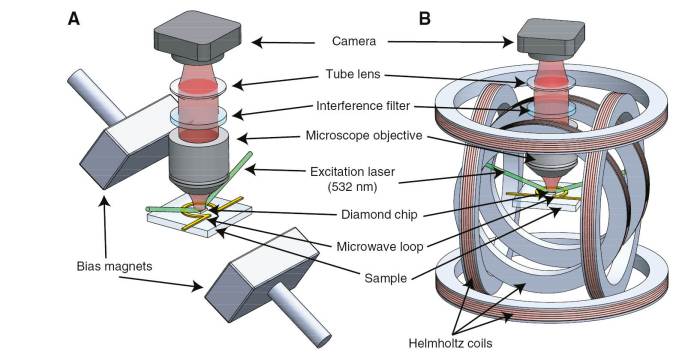

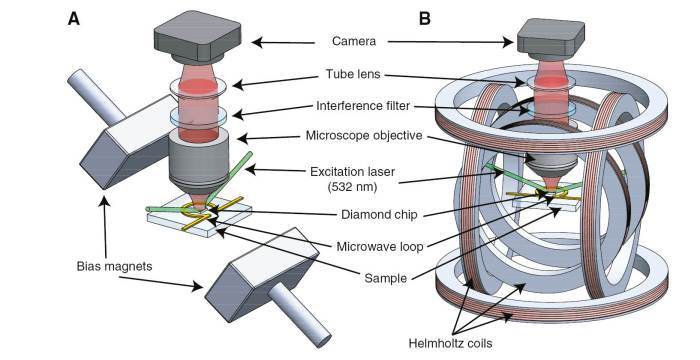

This microscope harnesses the unique properties of quantum phenomena, particularly entanglement and superposition, to achieve its remarkable capabilities.

- Entanglement:This phenomenon allows two or more particles to become correlated, even when separated by vast distances. In the quantum microscope, entangled photons are used to illuminate the chip, enabling the simultaneous measurement of multiple properties of the chip’s surface.

This allows for the detection of defects that would be missed by traditional microscopes.

- Superposition:This principle states that a quantum particle can exist in multiple states simultaneously. In the quantum microscope, the superposition of photons is exploited to enhance the signal-to-noise ratio, allowing for the detection of even the faintest imperfections.

Impact on Chip Manufacturing and Design

The introduction of the quantum microscope has profound implications for the future of chip manufacturing and design.

- Enhanced Defect Detection:The microscope’s superior resolution and sensitivity enable the detection of defects that are smaller than the wavelength of light used in traditional microscopes. This allows manufacturers to identify and eliminate defects that could lead to chip failures, resulting in higher yield rates and improved chip performance.

- Advancements in Chip Design:The ability to visualize and analyze chip features at the nanoscale level opens up new possibilities for chip design. Engineers can now create more complex and efficient chips, pushing the boundaries of miniaturization and performance.

- Acceleration of Innovation:By providing a deeper understanding of chip behavior and performance, the quantum microscope accelerates the pace of innovation in semiconductor technology. This leads to the development of faster, more powerful, and energy-efficient chips, driving advancements in various fields, including artificial intelligence, quantum computing, and high-performance computing.

Applications and Benefits: Quantum First Microscope Solve Chip Inspection

The quantum first microscope’s ability to surpass the limitations of conventional microscopes opens up a vast array of applications and benefits, particularly in the realm of chip inspection. Its enhanced resolution and sensitivity allow for unprecedented accuracy in defect detection, process control, and yield optimization, leading to significant improvements in the semiconductor industry.

Enhanced Defect Detection

The quantum first microscope’s ability to resolve features at the atomic level allows for the identification of defects that are simply invisible to conventional microscopes. This capability is crucial for ensuring the quality and reliability of chips, as even minute defects can lead to malfunctions or performance issues.

- Smaller Defects:The quantum microscope can detect defects as small as a few atoms, which is significantly smaller than the resolution limit of conventional microscopes. This capability allows for the identification of defects that are often missed by traditional inspection methods, leading to improved chip quality and reliability.

- Hidden Defects:The quantum microscope can penetrate deeper into materials, allowing for the detection of defects that are hidden beneath the surface. This is particularly important for inspecting complex chip architectures where defects can be buried within multiple layers of materials.

- Early Defect Detection:The quantum microscope’s sensitivity allows for the detection of defects at early stages of chip manufacturing, before they can cause significant problems. This early detection capability enables proactive corrective measures, preventing defects from propagating and leading to higher yields.

Improved Process Control

The quantum first microscope’s ability to provide detailed insights into the structure and composition of materials enables precise process control during chip manufacturing. This control leads to greater consistency and predictability in the production process, resulting in higher yields and reduced costs.

- Real-time Monitoring:The quantum microscope can be used for real-time monitoring of chip fabrication processes, providing instant feedback on the quality and uniformity of materials and structures. This real-time data allows for immediate adjustments to the manufacturing process, ensuring that defects are minimized and yields are maximized.

- Material Characterization:The quantum microscope can be used to characterize the properties of materials used in chip fabrication, providing valuable information on their composition, structure, and defects. This information is crucial for optimizing the selection and use of materials, ensuring that they meet the stringent requirements of modern chip manufacturing.

- Process Optimization:The quantum microscope can be used to optimize the various steps in the chip manufacturing process, from deposition and etching to lithography and packaging. By providing detailed insights into the process, the quantum microscope allows for the identification of bottlenecks and inefficiencies, leading to improved process control and higher yields.

Yield Optimization

The quantum first microscope’s ability to detect defects and control processes with unprecedented accuracy leads to significant improvements in chip yield. Higher yields translate into lower production costs and greater profitability for semiconductor manufacturers.

- Reduced Scrap Rates:The quantum microscope’s ability to identify and prevent defects early in the manufacturing process leads to significantly reduced scrap rates. This translates into lower production costs and higher profitability.

- Increased Throughput:The quantum microscope’s real-time monitoring capabilities enable more efficient process control, leading to increased throughput and faster production cycles. This translates into higher production volumes and increased revenue.

- Improved Product Quality:The quantum microscope’s ability to ensure defect-free chips leads to improved product quality and reliability. This translates into greater customer satisfaction and a stronger brand reputation.

Future Directions and Challenges

The development of quantum microscopes for chip inspection is still in its early stages, but the potential benefits are significant. Ongoing research and development efforts are focused on improving the capabilities of these microscopes and addressing the challenges that stand in the way of widespread adoption.

Ongoing Research and Development

The field of quantum microscopy for chip inspection is rapidly evolving. Several research groups and companies are actively working on improving the resolution, sensitivity, and speed of these microscopes. Key areas of focus include:

- Development of new quantum sensors:Researchers are working on developing more sensitive and precise quantum sensors, such as nitrogen-vacancy (NV) centers in diamond, to improve the signal-to-noise ratio and achieve higher resolution imaging. For instance, NV centers in diamond have shown promising results in detecting defects in silicon wafers with atomic-scale precision.

- Advanced quantum imaging techniques:Researchers are exploring new quantum imaging techniques, such as quantum interferometry and quantum entanglement, to enhance the resolution and sensitivity of quantum microscopes. These techniques can potentially enable the detection of smaller defects and impurities in chip materials.

- Integration with existing chip fabrication processes:Researchers are working on integrating quantum microscopes into existing chip fabrication processes to facilitate real-time inspection and quality control. This integration will require the development of compact and robust quantum microscopes that can operate in harsh manufacturing environments.

Potential Improvements and Advancements, Quantum first microscope solve chip inspection

The ongoing research and development efforts are expected to lead to significant improvements in the capabilities of quantum microscopes for chip inspection. Some potential advancements include:

- Enhanced resolution and sensitivity:Quantum microscopes are expected to achieve sub-nanometer resolution, enabling the detection of defects and impurities that are currently undetectable with conventional microscopes. This improved resolution will be crucial for inspecting increasingly complex and miniaturized chips.

- Faster imaging speeds:Current quantum microscopes can be slow, limiting their applicability for real-time inspection. Researchers are working on developing faster imaging techniques to enable real-time monitoring of chip fabrication processes.

- Non-destructive inspection:Quantum microscopes have the potential to perform non-destructive inspection, meaning that they can analyze chips without damaging them. This is particularly important for inspecting delicate and expensive chips.

- Improved defect characterization:Quantum microscopes can provide detailed information about the nature and location of defects in chips. This information can be used to optimize chip fabrication processes and improve the reliability of chips.

Technical Challenges and Hurdles

Despite the promising potential of quantum microscopy for chip inspection, several technical challenges need to be addressed before this technology can be widely adopted. These challenges include:

- Cost and complexity:Quantum microscopes are currently expensive and complex to build and operate. This cost and complexity can be a barrier to widespread adoption.

- Environmental sensitivity:Quantum sensors are sensitive to environmental noise, such as magnetic fields and temperature fluctuations. This sensitivity can make it difficult to operate quantum microscopes in harsh manufacturing environments.

- Scalability:Scaling up quantum microscopes to inspect large wafers or multiple chips simultaneously is a significant challenge. This will require the development of new technologies and approaches.

- Integration with existing infrastructure:Integrating quantum microscopes into existing chip fabrication processes will require significant modifications to existing infrastructure and workflows.

Impact on the Semiconductor Industry

The advent of quantum microscopy holds immense potential to revolutionize the semiconductor industry, impacting every stage of the chip lifecycle, from design to fabrication and testing. By providing unprecedented levels of resolution and sensitivity, this technology promises to address critical challenges that have plagued the industry for decades.

Impact of Quantum Microscopy on the Semiconductor Industry

The table below illustrates the potential impact of quantum microscopy on various aspects of the semiconductor industry.