New method ev motors circular reducing raw material imports – New Method for EV Motors: Circularity Reduces Raw Material Imports, is a game-changer in the automotive industry. The transition to electric vehicles is a critical step in mitigating climate change, but the traditional manufacturing processes for electric vehicle (EV) motors have significant environmental drawbacks.

The extraction and processing of raw materials, such as lithium, cobalt, and copper, have a substantial environmental footprint, leading to deforestation, habitat destruction, and pollution. Enter the circular economy, a model that aims to minimize waste and maximize resource utilization.

By adopting circular principles, we can reduce the reliance on virgin materials and create a more sustainable future for EV motor production.

This article explores innovative methods for reducing raw material imports in EV motor production, focusing on recycling, reuse, and alternative materials. We’ll delve into design principles that promote circularity, examine the role of collaboration, and envision the future of a circular EV motor industry.

The benefits are far-reaching, encompassing environmental protection, economic growth, and social responsibility.

The Need for Circularity in EV Motor Production

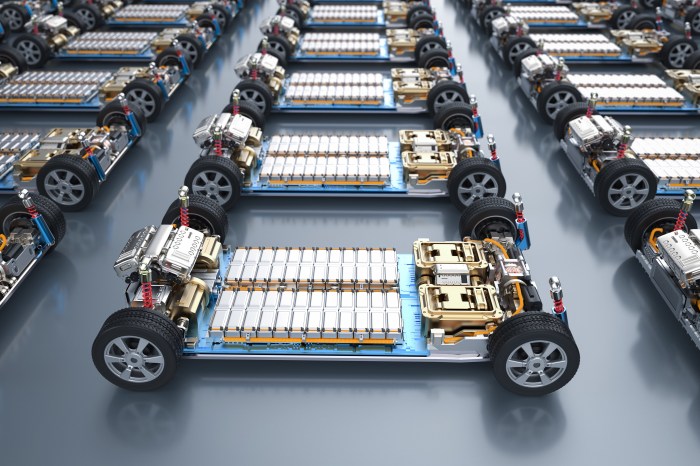

The electric vehicle (EV) revolution is rapidly gaining momentum, promising a cleaner and more sustainable future for transportation. However, the production of EV motors, a critical component of these vehicles, currently relies heavily on the extraction and processing of finite resources, posing significant environmental challenges.

This dependence on virgin materials contributes to a linear production model, where resources are extracted, processed, used, and ultimately discarded. This model is unsustainable, leading to resource depletion, pollution, and greenhouse gas emissions. To address these concerns and pave the way for a truly sustainable EV industry, adopting a circular economy approach is essential.

The Environmental Impact of Traditional EV Motor Manufacturing

Traditional EV motor manufacturing involves extracting raw materials like copper, aluminum, rare earth elements, and steel from the earth. This process can have severe environmental consequences, including:

- Land degradation and habitat destruction: Mining operations often disrupt ecosystems and destroy natural habitats.

- Water pollution: Mining and processing activities can contaminate water sources with heavy metals and other pollutants.

- Greenhouse gas emissions: The extraction, transportation, and processing of raw materials generate significant carbon emissions.

Furthermore, the production of EV motors requires significant energy consumption, often derived from fossil fuels, further contributing to environmental degradation.

The Concept of a Circular Economy

A circular economy aims to decouple economic growth from resource depletion by keeping materials and products in use for as long as possible. It involves three key principles:

- Reduce: Minimizing resource consumption by designing products for longevity, durability, and repairability.

- Reuse: Extending the lifespan of products through repair, refurbishment, and remanufacturing.

- Recycle: Recovering valuable materials from end-of-life products and incorporating them into new products.

This approach seeks to create a closed-loop system where resources are constantly reused and recycled, minimizing waste and environmental impact.

Examples of Circular Economy Models in Other Industries

The concept of a circular economy is not new. Several industries have already adopted circular principles, demonstrating its feasibility and benefits. For example:

- Electronics industry: Companies like Apple and Samsung are implementing take-back programs and using recycled materials in their products.

- Fashion industry: Brands like Patagonia and Levi’s are promoting clothing repair and encouraging customers to keep their garments for longer.

- Construction industry: Building materials are increasingly being designed for disassembly and reuse, reducing waste and promoting resource efficiency.

These examples highlight the potential of circular economy models to create a more sustainable future across various sectors.

New Methods for Reducing Raw Material Imports

The transition to electric vehicles (EVs) presents a significant opportunity to reduce our reliance on fossil fuels and mitigate climate change. However, the production of EV motors requires a substantial amount of raw materials, many of which are sourced from countries with questionable environmental and social practices.

To address this challenge, innovative technologies and processes are being developed to enhance the circularity of EV motor production, reducing raw material imports and minimizing environmental impact.

Recycling and Reusing Materials

Recycling and reusing materials are crucial for achieving circularity in EV motor production. These processes allow us to extract valuable materials from end-of-life motors and reintroduce them into the manufacturing cycle, reducing the need for virgin materials.

- Hydrometallurgical Processing:This method uses chemical solutions to extract valuable metals like copper, nickel, and cobalt from EV motor components. The process involves leaching, purification, and recovery stages, resulting in high-purity metals suitable for reuse in new motors.

- Pyrometallurgical Processing:This method involves heating and smelting EV motor components to extract valuable metals. While this method is more energy-intensive than hydrometallurgical processing, it can be used to recover metals from complex materials that are difficult to process hydrometallurgically.

- Mechanical Recycling:This method involves physically separating and processing EV motor components to recover reusable materials. Mechanical recycling can be used to recover steel, aluminum, and other materials from motors.

Using Alternative Materials

Exploring alternative materials with lower environmental impact is another crucial aspect of reducing raw material imports in EV motor production. These materials can offer comparable performance to traditional materials while minimizing environmental damage associated with extraction and processing.

- Rare Earth-Free Permanent Magnets:Traditional permanent magnets used in EV motors often rely on rare earth elements like neodymium, dysprosium, and praseodymium. These elements are scarce and extracted using environmentally damaging processes. Researchers are developing rare earth-free permanent magnets using alternative materials like iron, cobalt, and nickel, which are more abundant and can be extracted with lower environmental impact.

Discover more by delving into a chief automation officer could transform your business heres how further.

- Bio-based Composites:Traditional EV motor components like housings and stators often use plastics and composites derived from fossil fuels. Bio-based composites derived from renewable resources like plant fibers and biopolymers offer a sustainable alternative. These materials have a lower carbon footprint and can be composted at the end of their life cycle, further reducing environmental impact.

Benefits and Challenges of Different Methods

Each method for reducing raw material imports has its own set of benefits and challenges. Understanding these aspects is essential for making informed decisions about implementing these methods.

| Method | Benefits | Challenges |

|---|---|---|

| Recycling and Reusing Materials | – Reduces reliance on virgin materials

|

– Requires specialized infrastructure and expertise

|

| Using Alternative Materials | – Reduces reliance on scarce and environmentally damaging materials

|

– May require adjustments to manufacturing processes

|

Designing for Circularity in EV Motors

Designing EV motors with circularity in mind is crucial for minimizing environmental impact and maximizing resource recovery. By incorporating design principles that facilitate disassembly, recycling, and reuse, we can create a more sustainable future for electric mobility.

Modular Design

A modular design approach breaks down the EV motor into smaller, independent units. This simplifies disassembly and enables the replacement of individual components instead of replacing the entire motor. For example, the stator, rotor, and bearings can be designed as separate modules, allowing for easy access and replacement.

Standardized Components

Standardizing components across different EV motor models promotes interchangeability and reduces the need for specialized tools and equipment during disassembly and repair. This also simplifies the recycling process as standardized components can be sorted and processed more efficiently.

Material Selection

Choosing materials that are easily recyclable and have low environmental impact is essential for circularity. For example, using recycled aluminum or steel in the motor housing can reduce the demand for virgin materials. Additionally, using magnets made from rare earth elements that are easily separated from other materials simplifies recycling.

Material Separation, New method ev motors circular reducing raw material imports

Designing for material separation simplifies recycling and reduces contamination. For example, using different materials for the stator and rotor can make it easier to separate them during the recycling process.

Design for Disassembly

Designing for disassembly ensures that components can be easily separated for reuse or recycling. This can involve using fasteners that are easily removable, using different materials for different components, and avoiding the use of adhesives that make disassembly difficult.

The Role of Collaboration and Partnerships

The transition to a circular economy in EV motor production requires a collaborative effort involving manufacturers, suppliers, researchers, and policymakers. By working together, these stakeholders can drive innovation, overcome challenges, and accelerate the adoption of circular practices.Collaboration is essential to address the complexities of circularity, which spans the entire lifecycle of an EV motor, from raw material extraction to end-of-life recycling.

It facilitates the sharing of knowledge, resources, and best practices, enabling the development of more effective and sustainable solutions.

Successful Partnerships

Examples of successful partnerships highlight the transformative power of collaboration in advancing circularity in EV motor production.

- The Circular Economy for Electric Vehicles (CE4EV) project, a collaboration between the European Commission, industry partners, and research institutions, aims to develop a comprehensive circular economy framework for electric vehicles, including motors. This project fosters knowledge sharing and promotes the development of circular design principles and technologies.

- The partnership between Tesla and Redwood Materials, a company specializing in battery recycling, exemplifies the potential of collaboration between manufacturers and recycling companies. This partnership allows Tesla to recycle battery materials from its vehicles, reducing reliance on virgin materials and creating a closed-loop system.

- The collaboration between the University of Cambridge and the UK’s Department for Business, Energy and Industrial Strategy (BEIS)on the “Circular Economy for Electric Vehicles” project has led to the development of innovative recycling technologies and circular design guidelines for EV motors.

Overcoming Barriers to Collaboration

While collaboration is crucial, several barriers can hinder its effectiveness.

- Lack of trust and transparency: A lack of trust and transparency between stakeholders can impede the sharing of sensitive information and the development of effective partnerships. To overcome this, organizations should prioritize open communication, data sharing, and establishing clear frameworks for collaboration.

- Conflicting interests: Different stakeholders may have conflicting interests, such as competing for market share or prioritizing short-term profits over long-term sustainability. Addressing these conflicts requires finding common ground, establishing clear goals, and promoting a shared vision for circularity.

- Limited resources and funding: Developing and implementing circular solutions can be costly and resource-intensive. To overcome this barrier, governments and private investors need to provide incentives, funding, and support for collaborative initiatives.

The Future of Circularity in EV Motor Production: New Method Ev Motors Circular Reducing Raw Material Imports

The future of circularity in EV motor production is brimming with exciting possibilities. As we continue to innovate and develop new technologies, we can expect to see significant advancements in the way we design, manufacture, and recycle EV motors. The integration of emerging technologies, such as advanced recycling techniques and bio-based materials, will play a crucial role in shaping a more sustainable and circular EV motor industry.

The Impact of Emerging Technologies

The adoption of advanced recycling techniques and bio-based materials will have a profound impact on circularity in EV motor production.

- Advanced Recycling Techniques: Emerging technologies like hydrometallurgy and bioleaching can extract valuable metals from end-of-life EV motors with high efficiency and minimal environmental impact. These techniques offer a more sustainable alternative to traditional smelting processes, which are energy-intensive and generate significant emissions.

For instance, the company Redwood Materials is developing a closed-loop recycling system for lithium-ion batteries, aiming to recover nearly 100% of critical minerals from used batteries.

- Bio-Based Materials: Bio-based materials, such as bioplastics and biocomposites, offer a sustainable alternative to traditional petroleum-based materials used in EV motor components. These materials can be derived from renewable sources like plants and algae, reducing reliance on finite resources and minimizing environmental impact.

For example, companies like Ford are exploring the use of bio-based materials in their vehicle components, including parts for electric motors.

A Timeline for Circularity

The transition towards a circular EV motor industry is a gradual process that involves several key milestones and advancements.

- 2025-2030:Widespread adoption of design for disassembly and recyclability principles in EV motor manufacturing. Development and commercialization of advanced recycling technologies, such as hydrometallurgy and bioleaching.

- 2030-2035:Increased use of bio-based materials in EV motor components. Establishment of robust closed-loop recycling systems for critical minerals and materials.

- 2035-2040:Development of innovative circular business models that incentivize the reuse and recycling of EV motor components. Emergence of a circular economy for EV motor production, where resources are continuously reused and recycled.

Economic and Social Benefits

A circular economy for EV motor production offers significant economic and social benefits.

- Economic Benefits:Reduced reliance on raw material imports, lower production costs, and new revenue streams from the sale of recycled materials. For instance, a circular economy can reduce the reliance on mining operations, which can be costly and environmentally damaging.

- Social Benefits:Creation of new jobs in the recycling and circular economy sectors. Increased resource efficiency and reduced environmental impact, contributing to a more sustainable and equitable society.