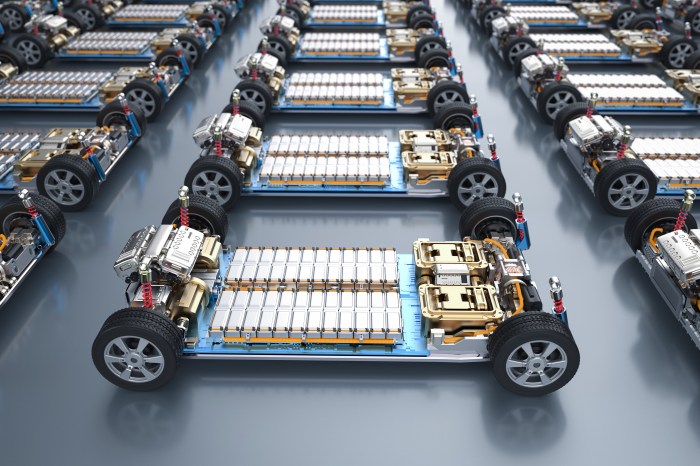

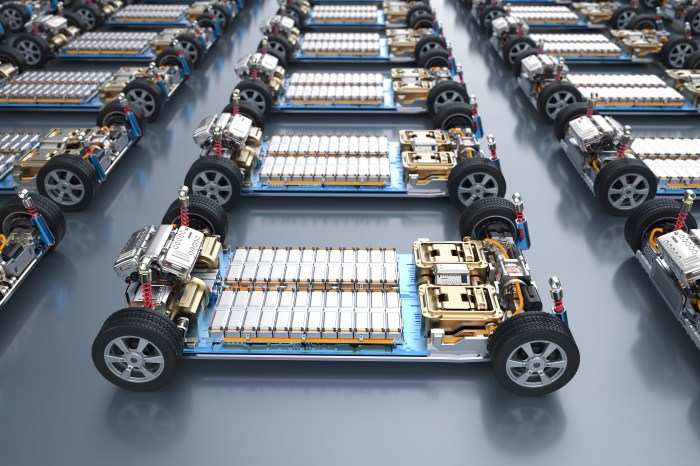

Helixx Factory in a Box promises affordable EV production worldwide, revolutionizing the way electric vehicles are manufactured. This innovative concept offers a modular and scalable approach to EV production, making it accessible to a wider range of manufacturers and locations.

The Helixx Factory in a Box consists of prefabricated modules that can be easily assembled and customized to suit specific needs, allowing for localized EV production even in remote areas.

This approach has the potential to significantly impact the global EV market, democratizing EV production and making it more affordable for consumers worldwide. By bringing EV manufacturing closer to consumers, the Helixx Factory in a Box can reduce transportation costs and emissions, contributing to a more sustainable and environmentally friendly automotive industry.

The Helixx Factory in a Box: Helixx Factory In A Box Promises Affordable Ev Production Worldwide

The Helixx Factory in a Box is an innovative concept that promises to revolutionize the production of electric vehicles (EVs) worldwide. It offers a modular and scalable approach to EV manufacturing, making it possible to set up efficient and affordable production lines in various locations, even in remote areas.

Key Features of the Helixx Factory in a Box

The Helixx Factory in a Box is designed to be a self-contained, transportable, and rapidly deployable production facility. Its key features include:

- Modular Design:The factory is built using prefabricated modules, which can be easily assembled and disassembled, allowing for flexible configurations and quick setup times.

- Scalability:The modular design allows for easy expansion as production needs grow. Additional modules can be added to increase capacity without significant disruption to existing operations.

- Advanced Automation:The factory incorporates advanced automation technologies, including robotic arms and AI-powered systems, to enhance efficiency and reduce labor costs.

- Sustainable Practices:The Helixx Factory in a Box is designed with sustainability in mind, incorporating energy-efficient technologies and minimizing environmental impact.

Impact on the Global EV Market

The Helixx Factory in a Box has the potential to significantly impact the global EV market by:

- Lowering Production Costs:By streamlining the manufacturing process and reducing labor requirements, the factory in a box can significantly lower production costs, making EVs more affordable for a wider range of consumers.

- Expanding EV Production Capacity:The modular and scalable nature of the factory allows for rapid deployment and expansion, enabling increased EV production capacity in various regions around the world.

- Promoting Localized EV Production:The ability to set up production facilities in remote locations can foster localized EV manufacturing, reducing reliance on global supply chains and supporting local economies.

- Accelerating the Transition to EVs:By making EV production more accessible and affordable, the Helixx Factory in a Box can accelerate the global transition to electric vehicles, contributing to a cleaner and more sustainable future.

Benefits of a Modular and Scalable Approach

A modular and scalable approach to EV manufacturing offers several advantages, including:

- Flexibility:Modular designs allow for customization and adaptation to specific production requirements, ensuring optimal efficiency and output.

- Rapid Deployment:Prefabricated modules can be quickly assembled, reducing the time and cost associated with setting up a new production facility.

- Cost-Effectiveness:Modular construction often results in lower overall costs compared to traditional, site-built facilities.

- Reduced Environmental Impact:Modular components can be reused or recycled, minimizing waste and promoting sustainability.

Affordability and Accessibility

The Helixx Factory in a Box promises to revolutionize EV production by making it more affordable and accessible to a wider range of manufacturers and markets. This innovative approach aims to overcome the traditional barriers to EV adoption, particularly in developing countries.

Lowering Production Costs

The Helixx Factory in a Box significantly reduces the capital expenditure required to set up an EV manufacturing facility. This is achieved through several key factors:

- Modular Design:The factory is designed with modular components, allowing for customization and scalability to meet specific production needs. This eliminates the need for large, expensive, and inflexible factory infrastructure.

- Pre-Engineered Solutions:The factory comes equipped with pre-engineered components, reducing the need for extensive on-site engineering and construction. This significantly streamlines the setup process and lowers costs.

- Automation and Robotics:The factory incorporates advanced automation and robotics technologies, optimizing production processes and reducing labor costs. This allows for higher production volumes with fewer workers, contributing to cost savings.

- Local Sourcing:The modular design and pre-engineered components enable the sourcing of materials locally, reducing transportation costs and supporting local economies. This fosters a more sustainable and cost-effective production model.

Expanding EV Accessibility in Developing Countries

The Helixx Factory in a Box has the potential to democratize EV production and accelerate adoption in developing countries. This technology can overcome several challenges that have hindered EV adoption in these regions:

- High Initial Investment:The high cost of setting up traditional EV manufacturing facilities has been a significant barrier to entry for developing countries. The Helixx Factory in a Box offers a cost-effective solution, allowing for smaller-scale production with lower upfront investment.

- Limited Infrastructure:Many developing countries lack the infrastructure required for large-scale EV production. The modular design and pre-engineered components of the Helixx Factory in a Box make it suitable for deployment in locations with limited infrastructure, enabling localized EV production.

- Skill Gap:Developing countries often face a shortage of skilled labor in the automotive industry. The Helixx Factory in a Box incorporates user-friendly interfaces and automation technologies, reducing the need for specialized training and making it easier for local workers to operate and maintain the facility.

- Market Demand:The increasing demand for EVs in developing countries, driven by rising pollution levels and a desire for sustainable transportation solutions, can be effectively met by the Helixx Factory in a Box. It allows for localized production of EVs tailored to the specific needs and preferences of these markets.

Partnerships and Collaborations

The Helixx Factory in a Box can be leveraged through partnerships and collaborations to further accelerate EV adoption and achieve wider impact:

- Government Agencies:Partnerships with government agencies can provide incentives and support for the deployment of the Helixx Factory in a Box, promoting localized EV production and supporting national sustainability goals. For example, governments could offer subsidies or tax breaks to companies adopting this technology.

- Automotive Manufacturers:Collaborations with automotive manufacturers can leverage their expertise in vehicle design and production, integrating the Helixx Factory in a Box into their existing supply chains. This can create a more robust and efficient EV ecosystem, benefiting both manufacturers and consumers.

- Non-Profit Organizations:Partnerships with non-profit organizations can focus on promoting sustainable transportation solutions in developing countries. These organizations can provide technical assistance, training, and financial support to local entrepreneurs and communities interested in setting up EV manufacturing facilities using the Helixx Factory in a Box.

- Educational Institutions:Collaborations with educational institutions can foster innovation and research in EV technology, training future generations of engineers and technicians who can contribute to the development and implementation of sustainable transportation solutions. Universities and research institutions can utilize the Helixx Factory in a Box as a platform for experimentation and knowledge transfer.

Notice generative ai business customer issues for recommendations and other broad suggestions.

Environmental Sustainability and Impact

The Helixx Factory in a Box offers a unique approach to EV production, one that prioritizes environmental sustainability and minimizes the carbon footprint associated with traditional manufacturing. By decentralizing EV production, the Helixx Factory in a Box empowers local communities to become active participants in the transition to a cleaner, more sustainable future.

Reduced Transportation Costs and Emissions

Decentralized EV production significantly reduces the transportation costs and emissions associated with traditional EV manufacturing. By bringing production closer to consumers, the Helixx Factory in a Box eliminates the need for long-distance transportation of raw materials, components, and finished vehicles.

This localized approach minimizes the environmental impact of shipping and logistics, contributing to a cleaner and more sustainable supply chain.

- Reduced Fuel Consumption:By minimizing the distance traveled for transporting materials and vehicles, the Helixx Factory in a Box significantly reduces fuel consumption, leading to lower greenhouse gas emissions.

- Lower Transportation Costs:The reduction in transportation distance directly translates to lower transportation costs, making EVs more affordable and accessible to a wider range of consumers.

- Reduced Congestion:Decentralized production can alleviate traffic congestion on roads and highways, further reducing air pollution and improving overall transportation efficiency.

Environmental Footprint Comparison, Helixx factory in a box promises affordable ev production worldwide

The table below highlights the environmental footprint of a Helixx Factory in a Box compared to a traditional EV manufacturing facility:

| Factor | Helixx Factory in a Box | Traditional EV Manufacturing Facility |

|---|---|---|

| Carbon Emissions (per vehicle) | Significantly lower due to reduced transportation and localized sourcing | Higher due to long-distance transportation and centralized production |

| Energy Consumption | Lower due to smaller footprint and potential for renewable energy integration | Higher due to large-scale operations and reliance on grid electricity |

| Waste Generation | Reduced due to localized production and potential for recycling and reuse | Higher due to large-scale production and reliance on disposable materials |

“The Helixx Factory in a Box is a game-changer for sustainable EV production. By bringing manufacturing closer to consumers, we can reduce transportation emissions, create local jobs, and accelerate the adoption of electric vehicles.”

[Name of CEO or Founder]

Technological Advancements and Innovation

The Helixx Factory in a Box is a testament to the innovative power of modular design and advanced manufacturing technologies. Its ability to revolutionize EV production hinges on a unique blend of technologies, each contributing to its affordability, accessibility, and sustainability.

Key Technologies Enabling the Helixx Factory in a Box

The Helixx Factory in a Box leverages a combination of technologies to achieve its goals. Here are some of the key technologies:

- Modular Design:The factory is built using prefabricated modules, allowing for rapid assembly and deployment. This modularity also enables customization and scalability, allowing the factory to adapt to different production needs and locations.

- Automated Manufacturing:The factory incorporates robotic arms and automated systems for various tasks, including welding, painting, and assembly. This automation significantly increases efficiency and reduces reliance on manual labor.

- Digital Twins and Simulation:The factory uses digital twins to simulate and optimize production processes. This allows for virtual testing and optimization before actual production, reducing errors and waste.

- Cloud-Based Data Management:The factory utilizes cloud-based platforms for data storage, analysis, and communication. This allows for real-time monitoring of production processes and enables data-driven decision-making.

- Advanced Materials and Processes:The factory incorporates advanced materials and manufacturing processes, such as lightweight composites and additive manufacturing (3D printing), to enhance vehicle performance and reduce production costs.

Potential for Further Innovation and Advancements

The Helixx Factory in a Box is a constantly evolving platform, with continuous advancements in its technologies. Future innovations could include:

- Artificial Intelligence (AI):AI algorithms can be integrated into the factory’s operations for predictive maintenance, quality control, and process optimization.

- Advanced Robotics:More sophisticated robotic systems could be employed to perform complex tasks, further automating production processes.

- Sustainable Manufacturing Processes:Continued research and development in sustainable manufacturing techniques, such as closed-loop recycling and renewable energy integration, will further enhance the factory’s environmental impact.

- Internet of Things (IoT):Connecting the factory’s components through the IoT will enable real-time data collection and analysis, allowing for even more efficient and responsive production.

- Virtual and Augmented Reality (VR/AR):VR/AR technologies can be used for training, remote assistance, and improved visualization of production processes.

Role of Automation and Robotics

Automation and robotics play a crucial role in the Helixx Factory in a Box. They contribute to:

- Increased Efficiency:Automation significantly reduces the time and labor required for various tasks, leading to increased production efficiency.

- Improved Quality:Robots perform tasks with precision and consistency, leading to higher product quality and reduced defects.

- Enhanced Safety:Automation removes workers from hazardous environments, improving workplace safety.

- Cost Reduction:By reducing labor costs and increasing efficiency, automation contributes to lower production costs.

- Flexibility and Scalability:Automated systems can be easily reconfigured and scaled to meet changing production demands.