French car battery startup verkor eu china ev – French car battery startup Verkor is making waves in the European EV industry, aiming to challenge the dominance of Chinese giants like CATL. With the EU pushing for battery independence, Verkor’s emergence presents a fascinating case study in the global race for EV battery dominance.

Verkor’s ambition to become a major player in the European EV battery landscape is fueled by a strategic blend of technological innovation, strategic partnerships, and government support.

However, Verkor faces an uphill battle against established players like CATL and LG Chem, who have already secured significant market share and economies of scale. Verkor’s success will depend on its ability to innovate, attract investment, and navigate the complex regulatory landscape.

This blog delves into Verkor’s journey, exploring its strategies, challenges, and potential impact on the future of the European EV industry.

Verkor’s Role in the European EV Battery Landscape

Verkor, a French battery startup, is emerging as a key player in the European Union’s (EU) ambition to become a leader in the electric vehicle (EV) industry. The EU aims to reduce its reliance on foreign suppliers for EV batteries and establish a robust domestic battery supply chain.

Understand how the union of elon musk business leaders compassionate evidence can improve efficiency and productivity.

Verkor’s emergence is a significant step towards achieving this goal.

Verkor’s Challenges and Opportunities

Verkor faces a number of challenges in competing with established battery manufacturers like CATL (China) and LG Chem (South Korea). These companies have significant economies of scale, established supply chains, and extensive research and development (R&D) capabilities. However, Verkor also has several opportunities to succeed.

The European market is growing rapidly, and there is a strong demand for locally produced batteries. Verkor’s focus on sustainability and innovation could also give it a competitive edge.

Verkor’s Technology and Manufacturing Approach

Verkor’s technology and manufacturing approach are distinct from its major competitors. Verkor focuses on developing high-performance, sustainable, and cost-effective batteries. The company utilizes a combination of innovative technologies, including:

- Dry electrode technology: This technology reduces the need for water in the manufacturing process, leading to lower energy consumption and emissions.

- High-nickel cathode materials: These materials enable higher energy density, resulting in longer driving ranges for EVs.

- Recyclable battery components: Verkor is committed to developing batteries with a high degree of recyclability, promoting a circular economy.

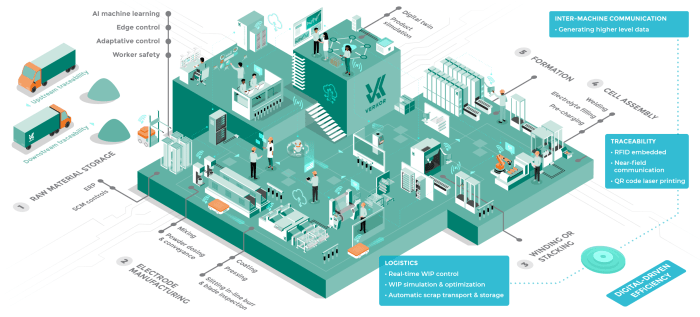

Verkor’s manufacturing approach emphasizes automation and digitalization, enabling efficient production and high-quality control. The company is also investing in research and development, aiming to develop next-generation battery technologies.

Verkor’s Potential Impact on the European EV Market and the Global Battery Supply Chain

Verkor’s success could have a significant impact on the European EV market and the global battery supply chain. By establishing a robust domestic battery supply chain, Verkor could help reduce the EU’s reliance on foreign suppliers and strengthen its position in the global EV market.

Verkor’s focus on sustainability and innovation could also drive the development of more environmentally friendly and efficient battery technologies, contributing to a more sustainable transportation sector.Verkor’s success could also have implications for the global battery supply chain. The company’s commitment to responsible sourcing and manufacturing practices could set a new standard for the industry, promoting sustainability and ethical sourcing.

Verkor’s emergence could also encourage other companies to invest in battery production in Europe, creating a more competitive and diversified global battery market.

Verkor’s Strategic Partnerships and Funding

Verkor, a French startup dedicated to revolutionizing the European electric vehicle (EV) battery landscape, has strategically forged partnerships and secured substantial funding to propel its ambitious goals. These collaborations and financial resources are crucial for Verkor’s development, technological advancement, and market penetration.

Key Partnerships

Verkor has established strategic alliances with various companies, research institutions, and government agencies to bolster its capabilities and accelerate its growth.

- Stellantis:This partnership, announced in 2021, involves the construction of a gigafactory in northern France. The collaboration aims to ensure a reliable and sustainable supply of EV batteries for Stellantis’s European production.

- Münchener Rück:Verkor partnered with this reinsurance giant in 2022 to secure a €1 billion insurance policy covering potential risks associated with the construction and operation of its gigafactory. This partnership demonstrates Verkor’s commitment to mitigating risks and securing long-term financial stability.

- CEA (French Alternative Energies and Atomic Energy Commission):Verkor collaborates with CEA on research and development, leveraging the institution’s expertise in materials science and battery technology. This partnership allows Verkor to access cutting-edge research and accelerate the development of innovative battery technologies.

- The French Government:Verkor has received significant support from the French government, including grants and funding for research and development. This support reflects the government’s commitment to promoting the development of a domestic EV battery industry and reducing reliance on foreign suppliers.

Funding Strategy

Verkor has secured significant funding through a combination of private investments, public grants, and potential government support. This diverse funding strategy aims to provide financial stability and fuel Verkor’s growth trajectory.

- Private Investments:Verkor has raised over €1 billion in private funding from investors like Bpifrance, IDinvest Partners, and EIT InnoEnergy. These investments have provided crucial capital for research and development, infrastructure development, and operational expenses.

- Public Grants:Verkor has received substantial grants from the French government, including the “France 2030” program, which aims to support strategic industries and technologies. These grants have contributed to the development of Verkor’s gigafactory and its research and development efforts.

- Potential Government Support:Verkor is actively pursuing additional government support, including potential investment from the European Union’s “InvestEU” program. This program aims to leverage public and private investments to support strategic projects in key sectors like clean energy and transportation.

Verkor’s Manufacturing and Production Plans

Verkor’s ambitious plans extend beyond securing funding and strategic partnerships. The company is actively developing a robust manufacturing infrastructure to support its goal of becoming a leading player in the European EV battery market.

Verkor’s Planned Manufacturing Facilities

Verkor has Artikeld plans to establish several manufacturing facilities across Europe. These facilities are strategically located to leverage regional expertise, access to raw materials, and proximity to key automotive customers.

- Dunkerque, France:This facility, Verkor’s flagship site, is expected to have an initial production capacity of 16 GWh per year, with the potential to expand to 40 GWh. Construction is underway, and the first phase of production is targeted for 2025.

The Dunkerque facility will focus on producing high-performance lithium-ion batteries for electric vehicles and other applications.

- Nantes, France:Verkor is also planning a second facility in Nantes, with an estimated capacity of 30 GWh per year. This site is expected to focus on developing and manufacturing next-generation battery technologies, including solid-state batteries.

- Other Locations:Verkor is exploring additional locations in Europe for future manufacturing sites, with a particular focus on countries with strong automotive industries and access to critical raw materials.

Key Technologies and Innovations

Verkor’s commitment to innovation is evident in its planned battery production process. The company aims to integrate advanced technologies and sustainable practices to enhance efficiency, reduce environmental impact, and ensure the long-term viability of its operations.

- Dry Electrodes:Verkor plans to utilize dry electrode technology, which eliminates the need for water-based slurry mixing, reducing energy consumption and waste generation. This process also allows for the use of higher-density active materials, improving battery performance.

- High-Voltage Cathodes:The company intends to incorporate high-voltage cathodes in its battery cells, enabling increased energy density and range for electric vehicles.

- Digital Twins:Verkor is investing in digital twin technology to create virtual representations of its manufacturing processes. This will allow for real-time optimization, predictive maintenance, and improved process control, ultimately enhancing efficiency and reducing downtime.

Environmental Sustainability and Responsible Sourcing

Verkor recognizes the environmental impact of battery production and is committed to sustainable practices throughout its value chain.

- Renewable Energy:Verkor aims to power its manufacturing facilities with renewable energy sources, reducing reliance on fossil fuels and minimizing carbon emissions.

- Closed-Loop Recycling:The company is actively developing a closed-loop recycling program to recover valuable materials from end-of-life batteries. This program will ensure the responsible management of battery waste and reduce reliance on virgin materials.

- Responsible Sourcing:Verkor is committed to sourcing raw materials responsibly and ethically, ensuring that its supply chain adheres to environmental and social standards. The company is working with partners to develop traceable and sustainable supply chains for critical minerals such as lithium, cobalt, and nickel.

Verkor’s Production Capacity Compared to Competitors

Verkor’s ambitious production plans position it as a significant player in the European EV battery market. However, it faces competition from established giants like CATL and LG Chem. Here’s a comparison of their planned production capacities:

| Company | Planned Production Capacity (GWh) | Location | Timeline |

|---|---|---|---|

| Verkor | 76 (estimated) | Europe (France, Germany, etc.) | 2025 onwards |

| CATL | >100 (estimated) | Germany, Hungary | 2024 onwards |

| LG Chem | >100 (estimated) | Poland, Hungary | 2024 onwards |

The EU’s Battery Strategy and Verkor’s Role

The European Union’s Battery Strategy is a comprehensive plan aimed at establishing a robust and competitive battery ecosystem in Europe. It aims to reduce the EU’s dependence on foreign suppliers, foster innovation, and create new jobs. Verkor, a French battery startup, is playing a crucial role in the implementation of this strategy, contributing to its overall objectives and contributing to the growth of the European battery market.

Verkor’s Alignment with the EU’s Battery Strategy

Verkor’s development and activities align with the key objectives of the EU’s Battery Strategy. Verkor is committed to developing and manufacturing sustainable and innovative battery solutions, contributing to the EU’s goal of becoming a global leader in battery technology. Verkor’s focus on sustainable production and recycling practices aligns with the EU’s emphasis on environmental responsibility and circular economy principles.

Impact of the EU’s Battery Strategy on Verkor

The EU’s Battery Strategy has a significant impact on Verkor’s growth and its ability to attract investment and talent. The strategy provides a supportive regulatory environment and financial incentives for battery companies like Verkor. The strategy’s focus on research and development creates opportunities for Verkor to collaborate with leading research institutions and universities in Europe.

The strategy’s emphasis on building a strong supply chain encourages companies like Verkor to establish manufacturing facilities and create jobs in Europe.

Comparison of Battery Development Strategies

The EU’s approach to battery development differs from those of other major economies, such as China and the United States. The EU’s strategy emphasizes a holistic approach, encompassing the entire battery value chain from raw materials to recycling. China has focused on building a strong domestic battery industry through government support and investment, while the United States has prioritized incentives for battery production and research.

The EU’s strategy aims to achieve a balance between promoting innovation and fostering a sustainable and competitive battery ecosystem.

China’s Dominance in the EV Battery Market: French Car Battery Startup Verkor Eu China Ev

China’s dominance in the global EV battery market is undeniable. Chinese companies hold a significant share of the global market, leading in both production and technological advancements. This dominance is a result of various factors, including government support, a robust domestic EV market, and a strong focus on research and development.

Factors Contributing to China’s Dominance, French car battery startup verkor eu china ev

China’s dominance in the EV battery market is attributed to several key factors:

- Government Support:The Chinese government has heavily invested in the development of its EV battery industry through subsidies, tax breaks, and strategic policies. This support has fostered innovation and accelerated the growth of Chinese battery manufacturers.

- Technological Advancements:Chinese battery companies have made significant strides in battery technology, particularly in areas like energy density, charging speed, and battery life. They have consistently pushed the boundaries of innovation, leading the global market in terms of technological advancements.

- Economies of Scale:China’s vast domestic EV market provides Chinese battery manufacturers with economies of scale, enabling them to produce batteries at lower costs compared to their international counterparts. This cost advantage allows them to offer competitive pricing, further solidifying their market position.

- Vertical Integration:Many Chinese battery manufacturers have integrated their operations vertically, controlling the entire supply chain from raw materials to battery production. This vertical integration provides them with greater control over costs, quality, and production efficiency.

Challenges and Opportunities for Verkor

Verkor faces significant challenges in competing with Chinese battery manufacturers in the European and global markets. The sheer scale of Chinese production and their technological advancements pose a formidable challenge. However, Verkor has several opportunities to carve out a niche in the market:

- Focus on Sustainability:Verkor can differentiate itself by focusing on sustainability and ethical sourcing of raw materials. This approach aligns with European values and could attract customers seeking responsible and environmentally friendly battery solutions.

- Innovation in Battery Technology:Verkor can invest in research and development to develop innovative battery technologies that address specific needs in the European market. This could involve focusing on battery chemistries, charging technologies, or safety features that are particularly relevant to European consumers.

- Strategic Partnerships:Verkor can leverage strategic partnerships with European automotive manufacturers to secure long-term supply contracts. This would provide a stable market for Verkor’s batteries and contribute to the growth of the European EV ecosystem.

Advantages and Disadvantages of Sourcing from China vs. Europe

The following table summarizes the key advantages and disadvantages of sourcing EV batteries from China versus European manufacturers like Verkor:

| Factor | China | Verkor (Europe) |

|---|---|---|

| Cost | Lower production costs due to economies of scale | Higher production costs, but potential for lower long-term costs through innovation and efficiency gains |

| Technology | Leading in battery technology, particularly in terms of energy density and charging speed | Focus on innovation and development of niche technologies relevant to the European market |

| Sustainability | Concerns over ethical sourcing and environmental impact of raw materials | Emphasis on sustainability and ethical sourcing of raw materials, aligning with European values |

| Supply Chain | Long and complex supply chain, potentially vulnerable to disruptions | Shorter and more localized supply chain, potentially more resilient to disruptions |

| Government Support | Strong government support for the EV battery industry | Growing government support for the European battery industry, but still behind China’s level of support |

The Future of Verkor and the European EV Industry

Verkor’s success could be a game-changer for the European EV industry, potentially enabling it to break free from its dependence on Asian battery manufacturers and become a leading force in the global electric vehicle market.

Verkor’s Potential Impact on the European EV Industry

Verkor’s success would have a profound impact on the European EV industry. It would create a robust domestic supply chain for EV batteries, reducing reliance on Asian manufacturers and bolstering the competitiveness of European carmakers. This would also create thousands of new jobs in the battery manufacturing sector, stimulating economic growth and fostering innovation.

Key Factors Influencing Verkor’s Future Success

Several key factors will determine Verkor’s future success, including:

- Technological Innovation:Verkor needs to continuously innovate to stay ahead of the competition. This includes developing more efficient and cost-effective battery chemistries, improving battery performance, and enhancing battery life.

- Market Demand:The growth of the European EV market will be crucial for Verkor’s success. Increasing demand for electric vehicles will drive the need for more batteries, providing Verkor with a larger market to serve.

- Government Support:Strong government support is essential for Verkor’s success. This includes financial incentives, regulatory frameworks that favor domestic battery production, and investment in research and development.

Challenges and Risks for Verkor

Verkor faces several challenges and risks in the future:

- Competition:The EV battery market is highly competitive, with established players like CATL and LG Energy Solution dominating the market. Verkor will need to compete aggressively to gain market share.

- Funding Constraints:Building a large-scale battery manufacturing facility requires significant capital investment. Verkor will need to secure adequate funding to meet its growth targets.

- Regulatory Hurdles:The battery industry is subject to complex regulations related to safety, environmental impact, and recycling. Verkor will need to navigate these regulations effectively to ensure its operations are compliant.

Verkor’s Growth Trajectory: A Five-Year Timeline

Verkor’s growth trajectory over the next five years can be envisioned as follows:

- 2023-2024:Completion of the first phase of battery production at Verkor’s facility in Dunkirk, France, with an initial capacity of 16 GWh.

- 2025-2026:Expansion of production capacity to 32 GWh, driven by increased demand from European carmakers.

- 2027-2028:Further expansion of capacity to 60 GWh, with a focus on developing new battery chemistries and technologies.