First metal part 3D printed in space ESA Airbus: This groundbreaking achievement marks a significant milestone in space exploration, paving the way for future on-demand manufacturing in the final frontier. The European Space Agency (ESA) and Airbus, in a collaborative effort, have successfully 3D printed a metal part aboard the International Space Station (ISS), a feat that could revolutionize the way we build and maintain structures in space.

This groundbreaking project demonstrates the potential of additive manufacturing to create complex components on demand, reducing the need for heavy and bulky materials to be shipped from Earth.

The 3D printed part, made of aluminum alloy, was designed to be a structural component for a future space mission. The printing process was carried out using a specially designed 3D printer that was sent to the ISS in 2021.

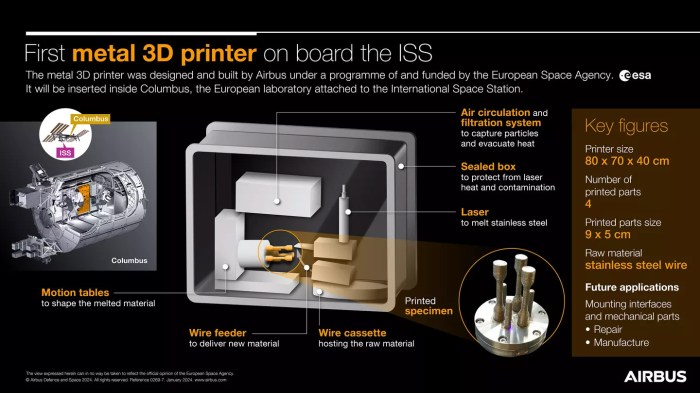

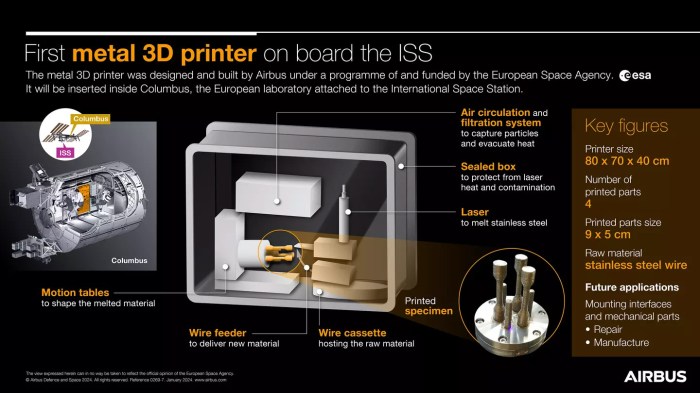

The printer uses a laser to melt and fuse together layers of metal powder, creating a solid object. This technology has the potential to be used to create a wide range of parts and structures in space, from tools and equipment to entire spacecraft.

ESA’s 3D Printing Mission

The European Space Agency (ESA) is taking a bold step into the future of space exploration with its 3D printing mission. This ambitious project signifies a paradigm shift in how we build and maintain infrastructure in space, opening doors to unprecedented possibilities for future space endeavors.

Significance for ESA

This mission holds immense significance for ESA, pushing the boundaries of space technology and establishing Europe as a frontrunner in this emerging field. By demonstrating the viability of 3D printing in space, ESA aims to:

- Reduce reliance on Earth-based manufacturing and supply chains, which are expensive and time-consuming.

- Enable on-demand production of components and tools, minimizing the need for pre-packaged equipment and allowing for greater flexibility in space missions.

- Open up new avenues for research and development in space, enabling the creation of innovative structures and objects tailored to specific needs.

Mission Objectives and Goals

The primary objective of ESA’s 3D printing mission is to validate the technology and its potential for space applications. Specifically, the mission aims to:

- Demonstrate the ability to 3D print functional objects in microgravity conditions.

- Assess the performance and reliability of 3D printing equipment in space.

- Explore the potential of different materials and printing techniques for space applications.

- Develop procedures and protocols for 3D printing in space, paving the way for future missions.

Timeline of the Mission

ESA’s 3D printing mission is a multi-phased endeavor with several key milestones:

- Phase 1 (2019-2021):Development and testing of the 3D printing system and materials in ground-based simulations.

- Phase 2 (2022-2023):Launch of the 3D printing system to the International Space Station (ISS).

- Phase 3 (2023-2024):In-space demonstrations and experiments, including printing of various objects and materials.

- Phase 4 (2025-present):Analysis of results, dissemination of findings, and development of future applications.

Challenges and Risks

D printing in space presents a unique set of challenges and risks:

- Microgravity Environment:The absence of gravity significantly affects the printing process, requiring specialized techniques and materials to ensure proper layer adhesion and structural integrity.

- Radiation Exposure:The harsh radiation environment in space can damage printing equipment and materials, necessitating robust shielding and radiation-resistant components.

- Limited Resources:Space missions have limited resources, including power, storage, and communication bandwidth, which pose constraints on the complexity and scale of 3D printing operations.

- Safety Concerns:Ensuring the safety of astronauts and the space environment is paramount, requiring rigorous testing and validation of 3D printed objects before deployment.

The First Metal Part

The first metal part 3D printed in space was a significant milestone in the advancement of additive manufacturing technology. This groundbreaking achievement opened up new possibilities for space exploration and construction, demonstrating the potential of 3D printing to revolutionize how we build and operate in space.

Material Used

The part was printed using an aluminum alloy called AlSiMg. This material was chosen for its strength, lightweight properties, and resistance to corrosion, making it suitable for structural applications in the harsh space environment.

Design and Function

The 3D printed part was a simple but crucial componenta small bracketdesigned to hold a cable. The bracket was specifically designed for the European Space Agency’s (ESA) 3D Printing Mission, which aimed to test and demonstrate the feasibility of 3D printing in space.

3D Printing Process in Space, First metal part 3d printed in space esa airbus

The 3D printing process in space was carried out using a selective laser melting (SLM)machine. This technology works by using a high-powered laser to melt and fuse powdered metal layer by layer, building up the desired object. The SLM machine was installed inside the International Space Station (ISS), where it was operated remotely by engineers on Earth.

Technical Specifications and Performance

The 3D printed bracket was approximately 20 millimeters in diameterand weighed a few grams. Despite its small size, the bracket met the required specifications for strength and durability. It was tested in space to ensure its performance and stability in the microgravity environment. The successful printing of this bracket demonstrated the potential of 3D printing to produce high-quality metal parts in space, paving the way for future applications in space exploration and construction.

Airbus’ Role

Airbus, a global aerospace giant, played a pivotal role in ESA’s 3D printing mission, contributing crucial expertise and technologies that paved the way for the successful creation of the first metal part in space. This mission marked a significant milestone in the field of space manufacturing, showcasing the potential of 3D printing to revolutionize future space exploration endeavors.

Airbus’ Contributions

Airbus’ contributions to the mission were multifaceted, encompassing the development of key technologies, expertise in space manufacturing, and a strong commitment to innovation.

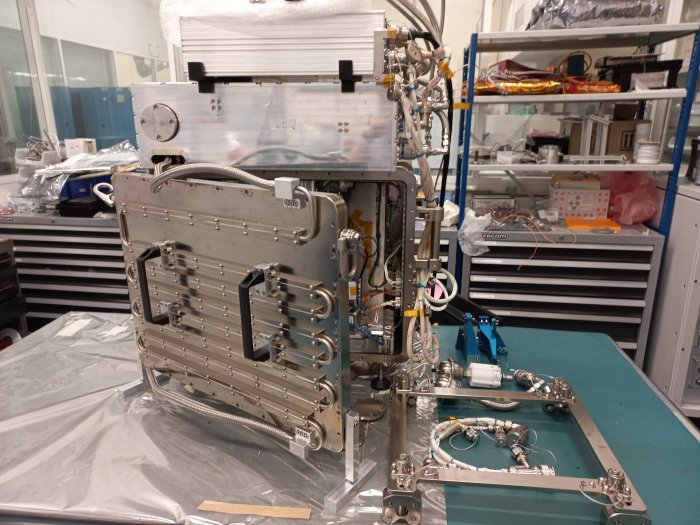

- Development of the 3D Printing System:Airbus, in collaboration with ESA, designed and developed the 3D printing system used in the mission. This system, known as the “Metal Additive Manufacturing System,” was specifically tailored for the harsh conditions of space, incorporating robust design features and advanced control systems.

- Expertise in Space Manufacturing:Airbus brought to the mission a wealth of experience in space manufacturing, having previously developed and launched various components for satellites and other spacecrafts. This expertise was crucial in ensuring the smooth integration and operation of the 3D printing system within the space environment.

- Materials Research and Development:Airbus’ expertise extended to the research and development of suitable metal materials for 3D printing in space. The team conducted extensive testing and analysis to identify and optimize materials that could withstand the extreme temperatures, radiation, and vacuum conditions of space.

Understand how the union of oxygen generating battery rock discovery life on earth can improve efficiency and productivity.

Airbus’ Role Compared to Other Partners

Airbus played a leading role in the 3D printing mission, working closely with ESA and other partners to achieve the project’s objectives. While ESA provided the overall mission direction and coordination, Airbus was responsible for the development and implementation of the 3D printing technology.

Other partners, such as the German Aerospace Center (DLR), contributed expertise in specific areas like material science and manufacturing processes.

Impact on Airbus’ Future Space Endeavors

The successful completion of the 3D printing mission has significantly impacted Airbus’ future space endeavors, highlighting the potential of this technology to revolutionize the way spacecraft and other space infrastructure are built. This project has further strengthened Airbus’ commitment to research and development in the field of space manufacturing, paving the way for future innovations in space exploration.

Implications for Future Space Exploration: First Metal Part 3d Printed In Space Esa Airbus

This groundbreaking achievement opens up a new era of possibilities for space exploration, where 3D printing could become an essential tool for building, repairing, and even sustaining human presence beyond Earth.

Potential Applications of 3D Printing in Space

The ability to print structures, tools, and even spare parts on demand in space has the potential to revolutionize how we explore and operate in the final frontier.

- Construction of Habitats and Infrastructure:3D printing could be used to build habitats, modules, and even entire space stations on the Moon, Mars, or other celestial bodies. This would eliminate the need to transport heavy and bulky materials from Earth, significantly reducing launch costs and logistical challenges.

- On-Demand Manufacturing:3D printing allows for the creation of customized tools, equipment, and spare parts as needed, eliminating the need for extensive stockpiles and reducing the risk of mission delays due to component failures. This is especially crucial for long-duration missions, where resupply missions are infrequent or impossible.

- Resource Utilization:3D printing can be used to process and utilize resources found on other planets and moons, such as lunar regolith or Martian soil, to create building materials, tools, and even fuel. This would allow for greater self-sufficiency and reduce reliance on Earth-based resources.

- Scientific Research and Experimentation:3D printing enables the creation of specialized equipment and instruments for scientific research and experimentation in space, allowing for more flexible and adaptable scientific missions.

Benefits and Drawbacks of 3D Printing for Space Manufacturing

While the potential benefits of 3D printing in space are significant, there are also challenges and drawbacks to consider.

- Benefits:

- Reduced Launch Mass and Cost:3D printing eliminates the need to transport heavy and bulky materials from Earth, significantly reducing launch mass and cost.

- On-Demand Manufacturing:3D printing allows for the creation of customized tools, equipment, and spare parts as needed, reducing reliance on Earth-based supply chains and minimizing the risk of mission delays due to component failures.

- Resource Utilization:3D printing can be used to process and utilize resources found on other planets and moons, enabling greater self-sufficiency and reducing reliance on Earth-based resources.

- Flexibility and Adaptability:3D printing allows for the creation of custom-designed structures and components, providing flexibility and adaptability for different mission requirements and environments.

- Drawbacks:

- Reliability and Durability:Ensuring the reliability and durability of 3D-printed components in the harsh space environment is a major challenge.

- Material Limitations:The range of materials that can be used in space-based 3D printing is currently limited, which may restrict the types of structures and components that can be created.

- Power Consumption:3D printing can be energy-intensive, requiring significant power resources, which may be a constraint in space missions.

- Maintenance and Repair:Maintaining and repairing 3D printing equipment in space can be challenging and costly.

Scenario for Revolutionizing Space Exploration

Imagine a future where astronauts on a mission to Mars can 3D print their own habitats, vehicles, and tools using materials extracted from the Martian soil. They can create customized equipment for scientific research, repair damaged components on the fly, and even build additional modules for their base as their mission progresses.

This scenario, powered by 3D printing, would significantly enhance the feasibility and sustainability of long-duration missions to Mars and beyond.

Potential Applications in Different Space Environments

| Space Environment | Potential Applications of 3D Printing |

|---|---|

| Low Earth Orbit (LEO) | Construction of modular space stations, repair of satellites, creation of scientific instruments, production of spare parts for spacecraft. |

| Moon | Construction of lunar bases, extraction and processing of lunar regolith for building materials, production of tools and equipment for lunar exploration, fabrication of radiation shielding for habitats. |

| Mars | Construction of Martian habitats and infrastructure, extraction and processing of Martian soil for building materials, production of tools and equipment for Martian exploration, fabrication of fuel for Martian rovers and vehicles. |

| Asteroids | Extraction and processing of asteroid resources for building materials, fuel, and other valuable materials, construction of mining facilities, production of tools and equipment for asteroid exploration. |

Technological Advancement

This groundbreaking achievement in space-based 3D printing is a testament to the remarkable advancements in technology that have paved the way for this milestone. This section will delve into the key technological innovations that enabled this breakthrough, highlighting the specific contributions of ESA and Airbus, and exploring the future potential of 3D printing in space exploration.

ESA and Airbus Contributions

The success of this mission is a direct result of the combined efforts of ESA and Airbus, each contributing unique expertise and innovations to the project. ESA, with its extensive experience in space exploration, provided the crucial framework for the mission, ensuring the 3D printer’s integration into the International Space Station (ISS) and its operation in the harsh space environment.

Airbus, a leading aerospace company with expertise in advanced manufacturing, developed the innovative 3D printer itself, incorporating features specifically designed for space applications.

Key Technological Advancements

This breakthrough in space-based 3D printing is a culmination of several key technological advancements:

- Miniaturization and Lightweight Design:The 3D printer used in this mission is remarkably compact and lightweight, making it suitable for integration into the ISS’s limited space. This was achieved through meticulous design and the use of advanced materials, ensuring minimal impact on the station’s resources.

- Closed-Loop System for Material Handling:The printer operates within a closed-loop system, meaning all material handling processes are contained within the printer itself. This is crucial for space applications, as it eliminates the risk of material contamination or loss in the microgravity environment.

- Advanced Software and Control Systems:The 3D printer is equipped with sophisticated software and control systems that enable precise control over the printing process, ensuring the production of high-quality metal parts. These systems also facilitate remote monitoring and control, allowing engineers on Earth to oversee the printing process.

- Robustness and Reliability:The 3D printer is designed to withstand the harsh conditions of space, including extreme temperatures, radiation, and vibrations. This was achieved through rigorous testing and the use of high-performance materials and components.

Future Potential of 3D Printing in Space

The successful demonstration of metal 3D printing in space opens up a vast array of possibilities for future space exploration. Here are some key applications:

- On-Demand Manufacturing:3D printing can enable the production of tools, spare parts, and even structural components on demand, eliminating the need for large inventories and reducing reliance on resupply missions.

- Customized Designs:3D printing allows for the creation of highly customized parts, tailored to specific needs and environments. This is particularly valuable in space exploration, where weight, size, and functionality are critical factors.

- Exploration of Remote Locations:3D printing can be used to create structures and equipment for exploring remote locations on other planets or moons, minimizing the need for heavy and expensive equipment to be transported from Earth.

- Material Innovation:3D printing in space can facilitate the development of new materials and alloys optimized for the specific conditions of space, pushing the boundaries of material science.

Timeline of Key Milestones in Space-Based 3D Printing

- 1990s:Initial research and development of 3D printing technologies for space applications.

- 2000s:The first successful demonstration of 3D printing in space, with the use of plastic materials.

- 2010s:Continued development and refinement of 3D printing technologies, with a focus on metal printing and improved reliability.

- 2020s:The first successful demonstration of metal 3D printing in space, marking a significant milestone in the development of this technology.