Fabricnano cell free biotech startup microplastics – Fabricnano, cell-free biotech startups, and microplastics—these seemingly disparate elements are converging to shape the future of materials and sustainability. Fabricnano, a revolutionary new class of textiles, harnesses the power of nanotechnology to create materials with exceptional properties, from enhanced durability to self-cleaning capabilities.

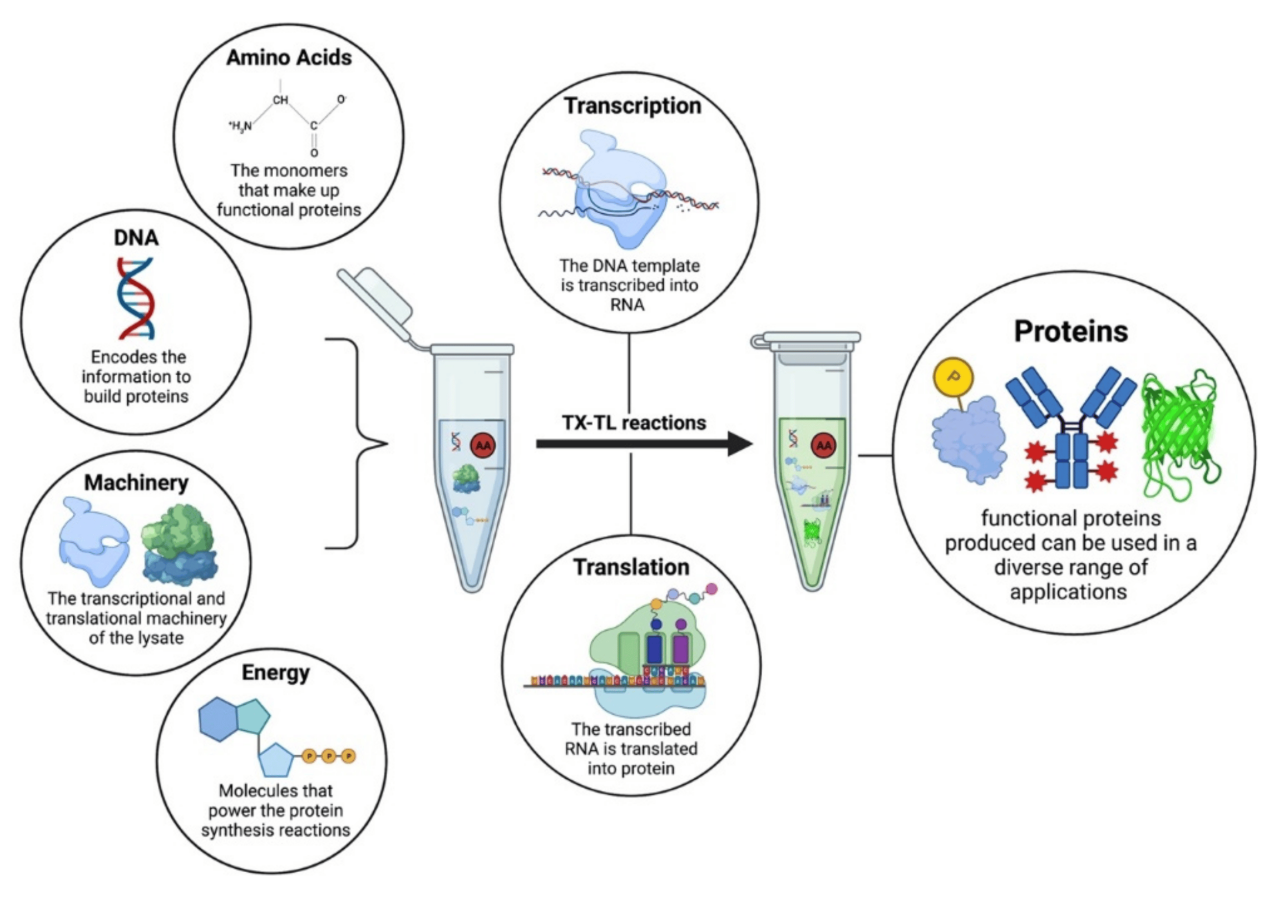

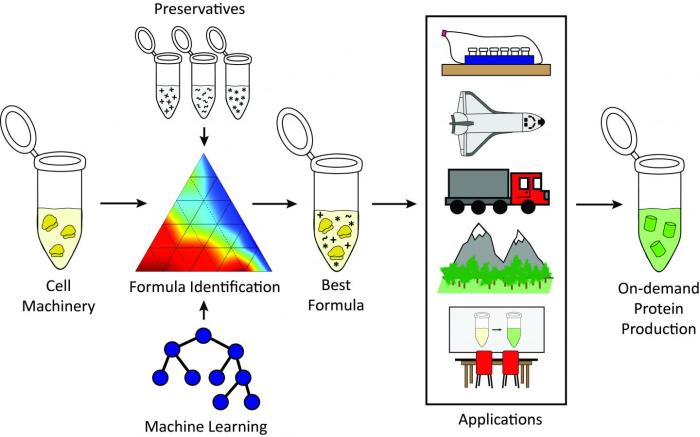

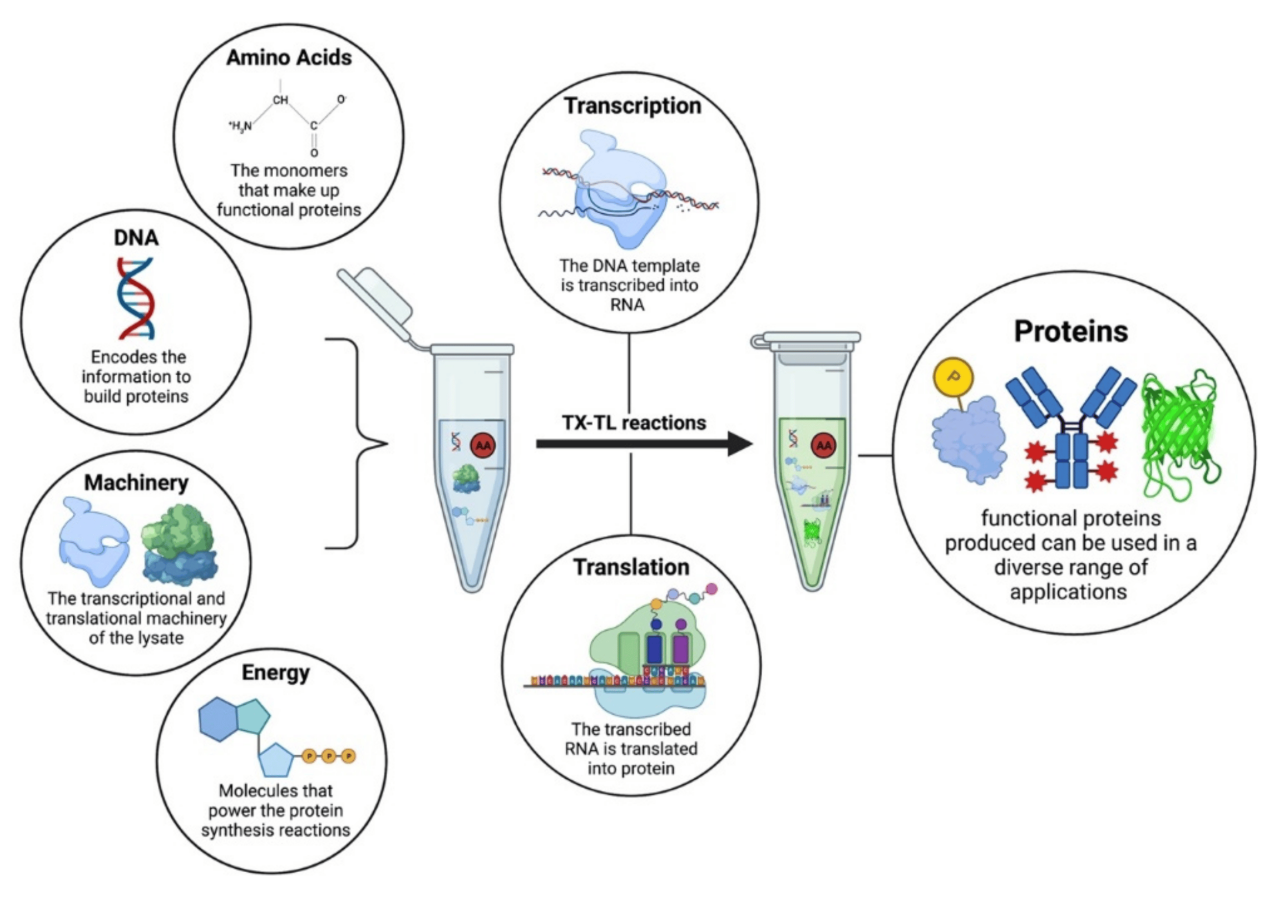

Cell-free biotechnology, a rapidly evolving field, allows scientists to produce valuable biomolecules and materials outside of living cells, opening up exciting possibilities for fabricnano production. But amidst this innovation, the issue of microplastics looms large. As we delve deeper into this complex intersection, we’ll explore the potential of fabricnano to mitigate microplastic pollution while addressing ethical and environmental concerns.

The combination of fabricnano and cell-free biotechnology holds immense promise for addressing the challenges of traditional textile manufacturing. By leveraging the power of nanotechnology and cell-free systems, we can create materials that are not only more durable and functional but also more sustainable and environmentally friendly.

This approach has the potential to revolutionize the fashion industry, reducing our reliance on synthetic fibers and minimizing the environmental impact of textile production.

Fabricnano

Fabricnano is a revolutionary new type of material that is poised to transform a wide range of industries. Unlike traditional textiles, fabricnano is not woven from fibers but rather created through the precise arrangement of nanomaterials. This unique approach grants fabricnano exceptional properties that surpass those of conventional textiles, making it a promising candidate for numerous applications.

Properties of Fabricnano

Fabricnano’s properties are a direct result of its nanoscale construction. The precise arrangement of nanomaterials gives it unique characteristics, including:

- Exceptional Strength:Fabricnano exhibits remarkable tensile strength, making it significantly stronger than traditional fabrics. This strength arises from the strong bonds between the nanomaterials, which create a robust and resilient material.

- Lightweight:Despite its strength, fabricnano is remarkably lightweight. This is because its nanoscale structure allows for a high surface area-to-mass ratio, making it a highly efficient material.

- Flexibility:Fabricnano can be easily molded and shaped, allowing for the creation of complex and intricate designs. This flexibility is crucial for its applications in various industries.

- High Permeability:Fabricnano can be designed to allow for the controlled passage of gases and liquids. This property is particularly valuable in applications where breathability and fluid management are critical, such as in healthcare and protective clothing.

- Hydrophobicity:Fabricnano can be engineered to repel water and other liquids. This property makes it ideal for applications where water resistance is essential, such as in outdoor clothing and marine applications.

Applications of Fabricnano

The unique properties of fabricnano have opened up a wide range of potential applications across various industries.

- Clothing:Fabricnano’s strength, lightweight nature, and breathability make it an ideal material for high-performance athletic wear. It can also be used to create durable and comfortable clothing for everyday use.

- Healthcare:Fabricnano’s biocompatibility and permeability make it suitable for medical applications such as wound dressings, drug delivery systems, and artificial organs. Its antibacterial properties also make it a promising material for medical textiles.

- Electronics:Fabricnano’s conductivity and flexibility make it a potential candidate for use in flexible electronics, such as wearable sensors, displays, and energy storage devices.

- Construction:Fabricnano’s strength and lightweight nature make it suitable for use in construction materials, such as reinforced concrete and lightweight building panels.

- Aerospace:Fabricnano’s high strength-to-weight ratio and resistance to extreme temperatures make it a potential material for use in aerospace applications, such as spacecraft and aircraft components.

Environmental Impact

The environmental impact of fabricnano production is a crucial consideration. Compared to traditional textile manufacturing, fabricnano production offers several advantages:

- Reduced Water Consumption:Fabricnano production requires significantly less water compared to traditional textile manufacturing. This is because the process does not involve the cultivation of cotton or other natural fibers, which are water-intensive crops.

- Reduced Chemical Usage:Fabricnano production typically involves fewer chemical processes compared to traditional textile manufacturing, which can lead to reduced pollution and environmental damage.

- Recyclability:Fabricnano materials can be designed to be recyclable, reducing waste and promoting a circular economy. This contrasts with traditional textiles, which often end up in landfills.

Biotech Startups: Fabricnano Cell Free Biotech Startup Microplastics

Biotech startups are at the forefront of innovation, pushing the boundaries of what’s possible in various fields, including healthcare, agriculture, and materials science. Fabricnano, a technology that uses nanotechnology to create functional fabrics with enhanced properties, is a prime example of the exciting possibilities emerging from the biotech startup ecosystem.

These startups face unique challenges and opportunities, making their journey both demanding and rewarding.

For descriptions on additional topics like oxford physicists enlist atomic clocks in the hunt for dark matter, please visit the available oxford physicists enlist atomic clocks in the hunt for dark matter.

Challenges Faced by Fabricnano Startups, Fabricnano cell free biotech startup microplastics

The development of fabricnano technologies presents several hurdles for biotech startups.

- High Research and Development Costs:Fabricnano technologies often require significant investment in research and development (R&D). This includes the cost of developing new nanomaterials, optimizing manufacturing processes, and conducting rigorous testing to ensure safety and efficacy.

- Regulatory Hurdles:The regulatory landscape for nanomaterials is still evolving, and navigating these regulations can be complex and time-consuming. Startups must comply with various safety and environmental standards, which can add to the cost and timeline of product development.

- Scaling Up Production:Scaling up production of fabricnano materials can be challenging. The delicate nature of nanomaterials requires precise control over manufacturing processes to ensure consistent quality and performance.

- Competition:The market for functional fabrics is becoming increasingly competitive, with established players and emerging startups vying for market share. Fabricnano startups need to differentiate themselves by offering unique value propositions and demonstrating the benefits of their technologies.

Funding and Partnerships

Securing funding is crucial for the success of fabricnano startups.

- Venture Capital:Venture capitalists (VCs) play a vital role in funding early-stage biotech startups. VCs are typically interested in companies with high growth potential and a clear path to profitability. However, securing VC funding can be competitive, and startups need to have a compelling business plan and a strong team.

- Government Grants:Government grants are another important source of funding for biotech startups. These grants often support research and development, particularly in areas of national importance, such as sustainable materials or medical textiles.

- Strategic Partnerships:Partnerships with established companies in the textile industry can provide access to resources, expertise, and distribution channels. These partnerships can help startups accelerate their growth and reach a wider market.

Market Potential and Competitive Landscape

The market for fabricnano-based products is expected to grow significantly in the coming years.

- Applications in Various Industries:Fabricnano technologies have diverse applications across various industries, including apparel, healthcare, automotive, and aerospace. This broad market potential makes it an attractive space for startups.

- Growing Demand for Sustainable Materials:Consumers are increasingly demanding sustainable and environmentally friendly products. Fabricnano technologies can contribute to sustainability by reducing waste, using fewer resources, and improving product durability.

- Competitive Landscape:The fabricnano market is becoming increasingly competitive, with established players like DuPont and Gore-Tex, as well as emerging startups like Fabricnano. The key to success will be to differentiate oneself by offering unique value propositions, focusing on specific market niches, and building strong brand recognition.

Microplastics

Microplastics, tiny plastic particles less than 5 millimeters in diameter, are a growing environmental concern. They are ubiquitous in our environment, from the deepest oceans to the highest mountains, and pose a significant threat to human health and ecosystems.

Sources and Pathways of Microplastic Pollution

Microplastics originate from various sources, including the breakdown of larger plastic items, industrial processes, and the intentional addition of microbeads in personal care products. These particles can enter the environment through numerous pathways, including:

- Wastewater treatment plants:Microplastics are not effectively removed during wastewater treatment, allowing them to enter rivers, lakes, and oceans.

- Landfills:Microplastics can leach from landfills into surrounding soil and water bodies.

- Atmospheric deposition:Microplastics can be transported long distances through the air and deposited on land and water surfaces.

- Industrial activities:Manufacturing, agriculture, and construction industries release microplastics into the environment.

- Marine debris:Large plastic items in the ocean break down into microplastics over time.

Impact of Microplastics on Human Health and Ecosystems

The presence of microplastics in the environment raises concerns about their potential impact on human health and ecosystems.

- Human health:Ingestion and inhalation of microplastics can lead to respiratory problems, gastrointestinal issues, and potential hormonal disruption.

- Marine life:Microplastics can be ingested by marine organisms, leading to starvation, physical damage, and accumulation of toxins in the food chain.

- Ecosystems:Microplastics can alter the composition and functioning of ecosystems, affecting biodiversity and ecosystem services.

Role of Fabricnano in Mitigating Microplastic Pollution

Fabricnano, a company focused on developing innovative textile technologies, has the potential to play a significant role in mitigating microplastic pollution.

- Biodegradable textiles:Fabricnano is developing biodegradable textiles that break down into harmless substances after their useful life, reducing the accumulation of plastic waste in the environment.

- Reusable textiles:Fabricnano is promoting the use of reusable textiles as an alternative to disposable plastic products, reducing the demand for new plastic materials.

- Sustainable manufacturing processes:Fabricnano is committed to sustainable manufacturing processes that minimize the release of microplastics into the environment.

Sustainability and Ethical Considerations

The development and application of fabricnano technologies, while promising in terms of innovation and potential benefits, also raise significant ethical and sustainability concerns that need to be addressed. This section explores the ethical considerations surrounding fabricnano technologies and analyzes the environmental footprint of fabricnano production, comparing it to traditional textile manufacturing.

Ethical Considerations in Fabricnano Development and Use

The ethical considerations surrounding fabricnano technologies are multifaceted and require careful consideration. Some of the key ethical considerations include:

- Potential Health Risks:The use of nanomaterials in textiles could pose unknown health risks to workers involved in manufacturing, consumers, and the environment. Research is needed to assess the potential for nanomaterials to cause respiratory problems, skin irritation, or other health issues.

- Transparency and Labeling:Consumers should be informed about the presence of nanomaterials in textiles and their potential impacts. Clear labeling requirements and transparency in supply chains are crucial to ensure informed consumer choices.

- Environmental Justice:The production and disposal of fabricnano products must be conducted in a way that minimizes environmental harm, particularly in communities that are already disproportionately affected by pollution.

- Social Responsibility:Fabricnano technologies should be developed and implemented in a way that promotes fair labor practices, worker safety, and responsible sourcing of materials.

Environmental Impact of Fabricnano Production

The environmental impact of fabricnano production is a crucial consideration. While fabricnano technologies offer potential advantages in terms of resource efficiency and reduced waste, their production processes can also have environmental implications.

Comparison of Fabricnano and Traditional Textile Manufacturing

The following table compares the environmental impact of fabricnano production to traditional textile manufacturing across various metrics:

| Metric | Fabricnano Production | Traditional Textile Manufacturing |

|---|---|---|

| Water Usage | Significantly lower due to reduced dyeing and finishing processes | High water consumption for dyeing, washing, and finishing processes |

| Carbon Emissions | Lower due to reduced energy consumption in manufacturing and transportation | High carbon emissions from energy-intensive processes and transportation |

| Waste Generation | Lower due to reduced use of chemicals and less textile waste | Significant waste generation from textile production and disposal |

| Microplastic Release | Potential for reduced microplastic release due to enhanced durability and reduced washing frequency | High microplastic release from synthetic fibers during washing |

Sustainable Practices in Fabricnano Production

To mitigate the environmental impact of fabricnano production, several sustainable practices can be implemented:

- Use of Bio-based Nanomaterials:Employing nanomaterials derived from renewable sources, such as cellulose or chitin, can reduce reliance on fossil fuels and minimize environmental impact.

- Closed-Loop Manufacturing:Implementing closed-loop manufacturing systems that recycle and reuse resources can significantly reduce waste generation and resource depletion.

- Eco-friendly Production Processes:Adopting eco-friendly production processes, such as water-efficient dyeing techniques and energy-efficient manufacturing facilities, can minimize environmental footprint.

- End-of-Life Management:Developing strategies for responsible end-of-life management, including recycling and composting, can reduce the environmental impact of discarded fabricnano products.