Eu project seeks data driven faster shipbuilding – EU Project Aims for Data-Driven Faster Shipbuilding: Imagine a future where ships are built faster, more efficiently, and with greater safety, all thanks to the power of data. That’s the vision driving a groundbreaking EU project focused on revolutionizing the shipbuilding industry through data-driven techniques.

This ambitious initiative aims to harness the potential of data analysis and artificial intelligence (AI) to streamline shipbuilding processes, reduce costs, and improve overall efficiency. By integrating data into every stage of shipbuilding, from design to construction and beyond, the project seeks to transform the industry, making it more agile, sustainable, and competitive in the global market.

The EU Project

This EU project aims to revolutionize the shipbuilding industry by leveraging the power of data. It focuses on developing and implementing innovative data-driven solutions to improve efficiency, reduce costs, and enhance the overall shipbuilding process.

Project Objectives and Goals

The project seeks to achieve several key objectives, including:

- Developing a comprehensive data platform that integrates data from various sources, such as design, production, and logistics.

- Utilizing advanced analytics techniques to extract valuable insights from the collected data, enabling better decision-making and optimization.

- Implementing predictive modeling to anticipate potential problems and proactively address them, reducing delays and costs.

- Promoting collaboration and knowledge sharing among stakeholders in the shipbuilding industry, fostering innovation and best practices.

Impact on the Shipbuilding Industry

The project’s success is expected to significantly impact the shipbuilding industry by:

- Improving the efficiency and productivity of shipbuilding processes, leading to faster construction times and reduced costs.

- Enhancing the quality and reliability of ships by identifying and mitigating potential issues early on.

- Promoting sustainability by optimizing resource utilization and reducing waste.

- Creating new opportunities for innovation and technological advancements in the shipbuilding sector.

Data-Driven Shipbuilding

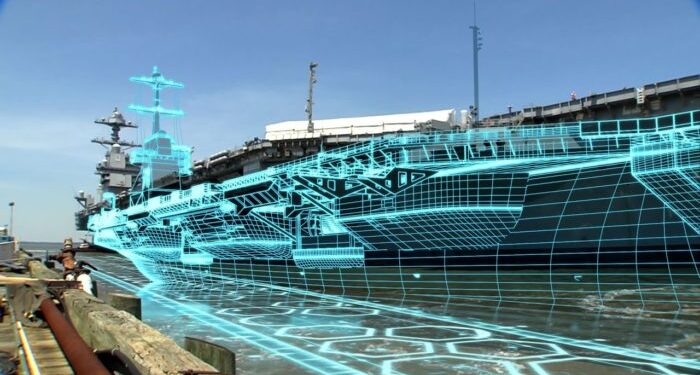

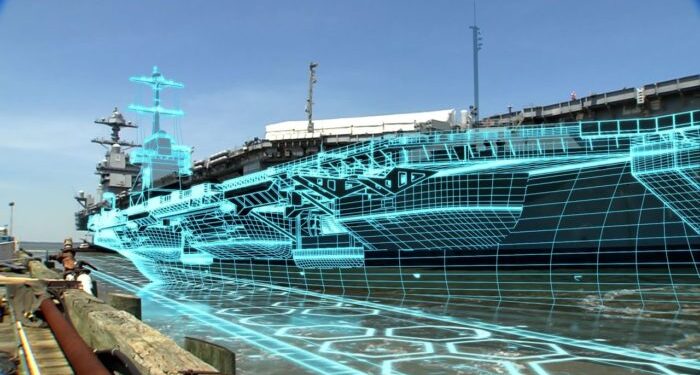

Data-driven shipbuilding is a revolutionary approach that leverages the power of data analysis and artificial intelligence (AI) to optimize every stage of the shipbuilding process, from design and engineering to production and maintenance. This paradigm shift aims to transform the traditional, often manual and inefficient shipbuilding practices into a more streamlined, efficient, and data-driven operation.

Data Integration and Analysis in Shipbuilding

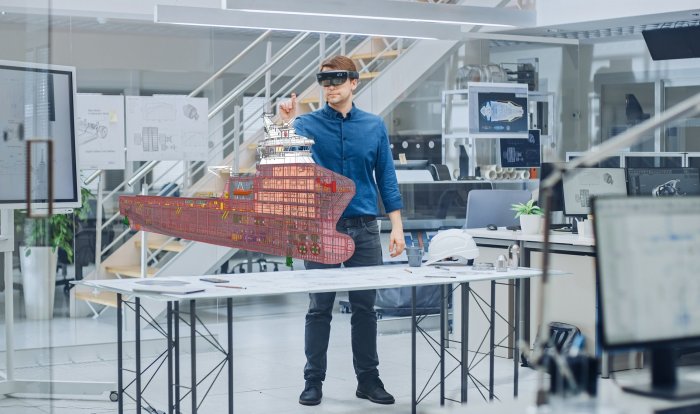

The integration of data analysis and AI into shipbuilding processes is a key aspect of data-driven shipbuilding. Data is collected from various sources, including sensors, design software, production systems, and external databases. This data is then processed and analyzed using sophisticated algorithms and AI tools to identify patterns, trends, and insights.

These insights can then be used to improve decision-making, optimize processes, and enhance overall efficiency.

- Design Optimization:AI-powered design tools can analyze vast amounts of data, including historical ship performance data, environmental factors, and regulatory requirements, to optimize ship design for specific operational needs. This can lead to improved fuel efficiency, reduced emissions, and enhanced safety.

- Production Planning:Data analysis can be used to optimize production schedules, allocate resources effectively, and minimize production delays. AI algorithms can predict potential bottlenecks and suggest solutions to maintain smooth production flow.

- Quality Control:Real-time data from sensors and cameras can be used to monitor production processes and identify potential defects early on. AI-powered vision systems can detect anomalies in welds, coatings, and other critical components, ensuring high-quality shipbuilding.

- Predictive Maintenance:By analyzing sensor data from ship systems, AI algorithms can predict potential failures and recommend maintenance schedules. This proactive approach helps minimize downtime and reduce maintenance costs.

Benefits of Data-Driven Shipbuilding

Data-driven shipbuilding offers a wide range of benefits, including:

- Improved Efficiency:By optimizing processes and reducing waste, data-driven shipbuilding can significantly improve overall efficiency, leading to shorter production cycles and faster delivery times.

- Reduced Costs:Optimized design, efficient production, and predictive maintenance can lead to substantial cost savings throughout the shipbuilding lifecycle.

- Enhanced Safety:Data analysis can identify potential safety risks and suggest mitigation strategies, leading to a safer working environment and improved ship operation.

- Increased Innovation:Data-driven insights can fuel innovation by identifying new design possibilities and optimizing existing technologies.

Data Sources and Collection: Eu Project Seeks Data Driven Faster Shipbuilding

The success of the Data-Driven Shipbuilding project hinges on the quality and accessibility of the data used. This section will explore the diverse data sources relevant to shipbuilding and Artikel strategies for effective data collection and integration.

Data Sources in Shipbuilding

Data sources in shipbuilding encompass a wide range of information, including:

- Ship Design and Engineering Data:This includes blueprints, specifications, material properties, and CAD models. These data are essential for understanding the ship’s structure, performance, and construction process.

- Production and Manufacturing Data:This covers information about production processes, equipment utilization, material consumption, and labor hours. This data is crucial for optimizing production efficiency and identifying areas for improvement.

- Supply Chain Data:This includes data on suppliers, materials, logistics, and inventory management. This data is critical for ensuring timely delivery of materials and managing supply chain disruptions.

- Operational Data:This encompasses data on ship performance, fuel consumption, maintenance records, and voyage information. This data is essential for optimizing ship operations and ensuring safety and compliance.

- Market Data:This includes data on shipbuilding trends, market demand, and competitor analysis. This data is essential for understanding the market landscape and making informed business decisions.

- Environmental Data:This includes data on weather conditions, sea state, and environmental regulations. This data is crucial for ensuring safe navigation and compliance with environmental regulations.

Data Collection Strategies, Eu project seeks data driven faster shipbuilding

Effective data collection in shipbuilding requires a comprehensive and systematic approach. The following strategies can be implemented:

- Data Integration Platform:A centralized platform for storing, managing, and analyzing data from diverse sources is crucial. This platform should be designed to ensure data consistency, accuracy, and accessibility.

- Automated Data Capture:Integrating sensors, IoT devices, and software applications can automate data capture from various sources, such as production lines, ships, and supply chain networks.

- Data Standardization and Cleaning:Implementing data quality control measures is essential to ensure data accuracy and consistency. This involves establishing data standards, cleaning data for errors and inconsistencies, and validating data against predefined rules.

- Data Security and Privacy:Implementing robust security measures is crucial to protect sensitive data from unauthorized access and cyber threats. This involves data encryption, access control, and regular security audits.

Data Collection Strategy for the EU Project

The EU Project, Data-Driven Shipbuilding, requires a specific data collection strategy to address its objectives. This strategy should include:

- Identifying key data sources:This involves mapping the data sources relevant to the project’s objectives, such as ship design data, production data, and operational data.

- Developing data collection protocols:This involves defining the methods for collecting data from each source, including data formats, frequency of collection, and quality control measures.

- Establishing data sharing agreements:This involves negotiating agreements with data providers to ensure access to the required data while adhering to data privacy and security regulations.

- Implementing a data governance framework:This involves defining roles and responsibilities for data management, ensuring data quality, and protecting data security.

Data Analysis and Modeling

The ability to analyze and model data is crucial for optimizing shipbuilding processes. By leveraging data analysis techniques, we can extract valuable insights, identify patterns, and predict outcomes, leading to improved efficiency, reduced costs, and enhanced ship performance.

Data Analysis Techniques in Shipbuilding

Data analysis techniques play a pivotal role in extracting meaningful information from shipbuilding data. These techniques enable us to understand trends, identify anomalies, and make informed decisions to optimize various aspects of the shipbuilding process.

Discover the crucial elements that make europe take note france bans short haul flights the top choice.

- Descriptive Analytics:This technique involves summarizing and describing key characteristics of the data, such as average build time, material consumption, and defect rates. This provides a baseline understanding of the shipbuilding process and highlights areas for improvement.

- Diagnostic Analytics:This technique focuses on identifying the root causes of problems or deviations from expected outcomes. For example, analyzing defect data can reveal specific manufacturing processes or material types contributing to quality issues.

- Predictive Analytics:This technique uses historical data to predict future outcomes, such as estimated build time, potential delays, or material requirements. Predictive models can be used to optimize resource allocation and minimize risks.

- Prescriptive Analytics:This advanced technique provides recommendations for actions to take based on data analysis. For example, a prescriptive model could suggest changes to the production schedule or material sourcing to improve efficiency or reduce costs.

AI Algorithms for Pattern Recognition

Artificial intelligence (AI) algorithms are increasingly being used in shipbuilding to identify patterns and insights from large datasets that would be difficult or impossible for humans to analyze manually. These algorithms can help us uncover hidden relationships and make more accurate predictions.

- Machine Learning:Machine learning algorithms can be trained on historical shipbuilding data to identify patterns and make predictions. For example, a machine learning model could be trained to predict the likelihood of a delay based on factors such as weather conditions, material availability, and workforce availability.

- Deep Learning:Deep learning algorithms are particularly effective at analyzing complex and unstructured data, such as images and text. In shipbuilding, deep learning could be used to analyze ship designs, identify potential defects in images, or automate document processing.

- Natural Language Processing (NLP):NLP algorithms can be used to analyze textual data, such as ship specifications, technical documentation, and project reports. This can help to extract key information, identify potential risks, and improve communication within the shipbuilding process.

Data Model for Shipbuilding Process Optimization

A data model can be created to demonstrate how data can be used to predict and optimize shipbuilding processes. This model can incorporate various data sources, such as historical build data, material specifications, supplier information, and weather data.

The model can be used to predict key metrics such as build time, cost, and quality, based on factors such as ship design, material choices, and production schedule.

The model can also be used to identify potential bottlenecks and areas for improvement. For example, by analyzing historical data on delays, the model could identify specific stages in the shipbuilding process that are prone to delays and suggest solutions to mitigate these risks.

Applications of Data-Driven Shipbuilding

Data-driven shipbuilding is not just about collecting and analyzing data; it’s about using that information to improve every aspect of the shipbuilding process. From design and production to operation and maintenance, data can be used to optimize processes, enhance performance, and ultimately deliver more efficient and sustainable ships.

Optimizing Production Processes

Data-driven techniques can be used to optimize various aspects of shipbuilding production, including:

- Production Planning and Scheduling: Data analysis can help identify bottlenecks and inefficiencies in the production process, allowing for better resource allocation and more efficient scheduling. This can lead to reduced lead times and improved overall productivity.

- Inventory Management: By analyzing historical data on material usage and demand, shipyards can optimize their inventory levels, reducing storage costs and minimizing the risk of stockouts.

- Quality Control: Data from sensors and other monitoring systems can be used to identify potential quality issues early in the production process, allowing for corrective action to be taken before defects become major problems.

- Predictive Maintenance: Data from sensors and maintenance records can be used to predict when equipment is likely to fail, allowing for proactive maintenance to be scheduled and prevent costly downtime.

Improving Ship Design

Data-driven techniques can be used to improve the design of ships in several ways, including:

- Hydrodynamic Optimization: Computational Fluid Dynamics (CFD) simulations can be used to analyze the flow of water around a ship’s hull, identifying areas for improvement in efficiency and reducing fuel consumption.

- Structural Optimization: Finite Element Analysis (FEA) can be used to analyze the stresses and strains on a ship’s structure, allowing for the design of lighter and stronger hulls.

- Performance Optimization: Data from real-world ship operations can be used to fine-tune the design of ships, optimizing their performance for specific routes and cargo types.

Enhancing Ship Performance

Data-driven techniques can be used to enhance ship performance in a number of ways, including:

- Fuel Efficiency: By analyzing data from sensors and navigation systems, ship operators can optimize their routes and speeds to minimize fuel consumption. This can lead to significant cost savings and reduced environmental impact.

- Safety and Security: Data from sensors and cameras can be used to monitor the ship’s environment and detect potential hazards, improving safety and security. This can also be used for incident investigation and analysis.

- Maintenance Optimization: Data from sensors and maintenance records can be used to predict when equipment is likely to fail, allowing for proactive maintenance to be scheduled and prevent costly downtime.

Real-World Examples

- Daimler’s Mercedes-Benz: Daimler’s Mercedes-Benz is using data-driven techniques to optimize the production process for its shipbuilding division. By analyzing data from sensors and other monitoring systems, the company has been able to identify bottlenecks and inefficiencies, leading to improved productivity and reduced lead times.

- Rolls-Royce: Rolls-Royce is using data-driven techniques to improve the performance of its marine engines. The company has developed a system that collects data from sensors on the engine, allowing for real-time monitoring and analysis of performance. This data is used to optimize engine performance and reduce fuel consumption.

- Maersk: Maersk, one of the world’s largest shipping companies, is using data-driven techniques to optimize its fleet operations. The company has developed a system that analyzes data from sensors and other monitoring systems, allowing for real-time tracking of ship performance and fuel consumption.

This data is used to optimize routes, speeds, and other operational parameters, leading to significant cost savings and reduced environmental impact.

Challenges and Opportunities

The journey towards data-driven shipbuilding, while promising, is not without its hurdles. Implementing such a paradigm shift requires careful consideration of various challenges, ethical implications, and the potential opportunities it presents.

Challenges of Implementing Data-Driven Shipbuilding

Data-driven shipbuilding faces a multitude of challenges that need to be addressed for successful implementation.

- Data Quality and Availability: Ensuring the quality, consistency, and availability of data is crucial. Data from various sources, such as sensors, design software, and historical records, needs to be integrated and standardized for effective analysis.

- Data Security and Privacy: Protecting sensitive data, such as intellectual property and customer information, is paramount. Robust security measures and data anonymization techniques are essential to maintain confidentiality and trust.

- Data Infrastructure and Scalability: Establishing a robust data infrastructure, including storage, processing, and analysis capabilities, is essential to handle the vast amounts of data generated in shipbuilding. Scalability is critical to accommodate future growth and increasing data volumes.

- Integration with Existing Systems: Integrating data-driven solutions with existing legacy systems can be complex and time-consuming. Compatibility issues and data migration challenges need to be addressed effectively.

- Skill Gap and Training: A skilled workforce capable of managing, analyzing, and interpreting data is crucial for successful implementation. Bridging the skills gap through training programs and upskilling initiatives is essential.

- Resistance to Change: Overcoming resistance to change from stakeholders, including shipbuilders, designers, and workers, is crucial. Clear communication, demonstration of benefits, and effective change management strategies are vital.

Ethical Considerations in Data Collection and Use

Data collection and use in shipbuilding raise significant ethical concerns that need to be carefully considered.

- Data Privacy and Anonymization: Protecting the privacy of individuals involved in shipbuilding, including workers, customers, and suppliers, is crucial. Data anonymization techniques and robust privacy policies are essential to ensure responsible data handling.

- Transparency and Accountability: Transparency in data collection and use is essential to build trust and ensure accountability. Clear guidelines and mechanisms for data access, sharing, and usage should be established.

- Bias and Discrimination: Algorithms used in data-driven shipbuilding should be carefully evaluated for bias and discrimination. Efforts should be made to ensure fairness and equity in decision-making processes.

- Job Displacement: The potential for job displacement due to automation and data-driven decision-making should be addressed proactively. Reskilling and upskilling programs can help workers adapt to changing job requirements.

Opportunities for Data-Driven Shipbuilding

Data-driven shipbuilding presents numerous opportunities for innovation and improvement across the shipbuilding lifecycle.

- Enhanced Design and Optimization: Data analysis can optimize ship design for efficiency, performance, and cost-effectiveness. Simulation and modeling tools can help predict and mitigate risks, leading to improved design outcomes.

- Improved Production Processes: Data-driven insights can optimize production processes, reducing waste, improving efficiency, and minimizing delays. Real-time monitoring and predictive maintenance can further enhance production efficiency.

- Predictive Maintenance and Asset Management: Data analysis can predict equipment failures and optimize maintenance schedules, reducing downtime and extending asset life. This can significantly improve operational efficiency and reduce maintenance costs.

- Enhanced Safety and Security: Data-driven solutions can enhance safety and security in shipbuilding operations. Real-time monitoring of critical systems and predictive analytics can help identify and mitigate potential risks.

- Sustainable Shipbuilding: Data analysis can help optimize ship design and operations for environmental sustainability. Reducing fuel consumption, minimizing emissions, and improving resource efficiency are key areas where data-driven approaches can contribute.