Vital3d 3d printed organs bioprinting kidney – Vital3D: 3D Printed Organs Bioprinting Kidney, is a groundbreaking field pushing the boundaries of medical innovation. Imagine a world where organ failure isn’t a death sentence, where patients can receive personalized, bio-engineered organs, eliminating the need for long waitlists and risky transplants.

This is the vision that Vital3D, a leading company in bioprinting, is striving to achieve. They are at the forefront of developing 3D printed organs, particularly focusing on the complex challenge of bioprinting kidneys.

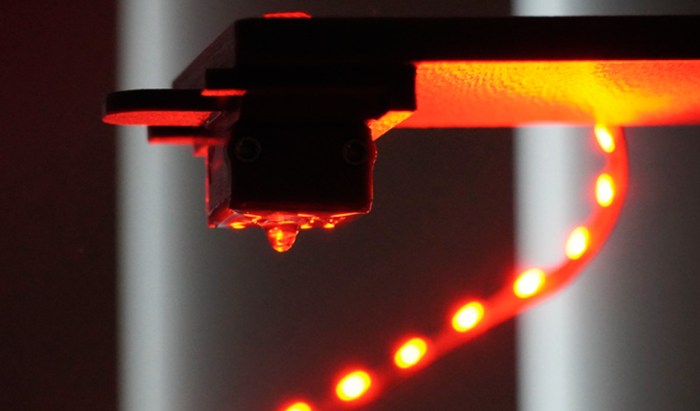

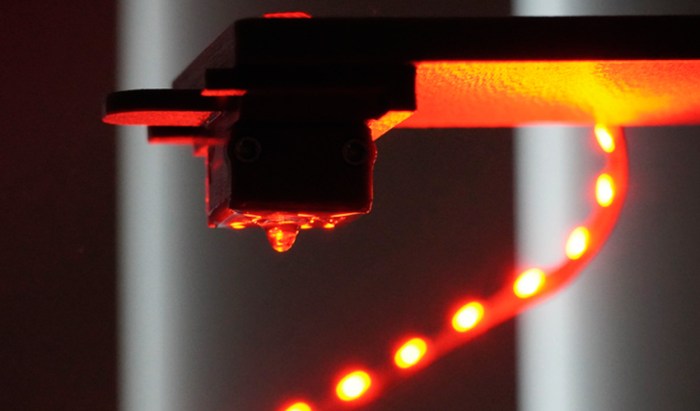

Vital3D’s expertise lies in their ability to harness the power of bioprinting to create functional, living tissues. By meticulously layering biocompatible materials and living cells, they are constructing intricate kidney structures that mimic the natural organ. Their approach involves using bioinks, which are specially formulated materials that act as the building blocks for these organs, allowing for the precise placement of cells and the formation of functional vascular networks.

This intricate process requires a deep understanding of bioengineering, cell biology, and material science, highlighting Vital3D’s commitment to scientific rigor and innovation.

Vital3D

Vital3D is a leading company in the field of bioprinting, specializing in the development and application of 3D printing technologies for creating functional human tissues and organs. The company’s mission is to revolutionize healthcare by providing innovative solutions for organ transplantation, drug discovery, and disease modeling.

Vital3D’s Expertise in Kidney Bioprinting

Vital3D’s expertise in 3D printed organ bioprinting is particularly evident in its focus on kidney bioprinting. The company has developed a unique bioprinting platform that enables the creation of complex, three-dimensional kidney structures with intricate vascular networks. This platform utilizes a combination of biocompatible materials, specialized printing techniques, and advanced bioengineering principles to mimic the intricate architecture and functionality of the human kidney.

Vital3D’s Innovative Technologies and Research Advancements in Kidney Bioprinting

Vital3D’s innovative technologies and research advancements in kidney bioprinting have significantly contributed to the field’s progress. Here are some key examples:

Bioprinting Platform for Kidney Tissue Engineering

Vital3D’s bioprinting platform is designed to create functional kidney tissues by precisely layering different cell types and biomaterials. This platform allows for the creation of complex, three-dimensional kidney structures with intricate vascular networks, which are essential for organ function.

Biocompatible Materials for Kidney Bioprinting

Vital3D has developed a range of biocompatible materials specifically designed for kidney bioprinting. These materials are biocompatible, meaning they do not elicit an immune response from the body, and support the growth and differentiation of kidney cells.

Advanced Bioengineering Principles for Kidney Bioprinting

Vital3D’s bioprinting platform incorporates advanced bioengineering principles to ensure the viability and functionality of the bioprinted kidney tissues. These principles include cell-cell interactions, biomaterial properties, and microfluidic control, all of which contribute to the development of functional kidney tissues.

Research Advancements in Kidney Bioprinting

Vital3D has been actively involved in research and development activities related to kidney bioprinting. The company has published numerous scientific papers in leading journals, demonstrating the potential of its bioprinting technology to create functional kidney tissues.

Examples of Vital3D’s Research Advancements

- Vital3D has successfully bioprinted functional kidney tubules, which are the basic functional units of the kidney, in vitro. These tubules exhibited key features of native kidney tubules, including the ability to filter blood and produce urine.

- Vital3D has also developed a bioprinted kidney model that can be used for drug testing and disease modeling. This model can be used to study the effects of drugs on kidney function and to model various kidney diseases, such as chronic kidney disease.

The Promise of 3D Printed Kidneys: Vital3d 3d Printed Organs Bioprinting Kidney

The need for kidney transplantation is increasing globally, with over 90,000 people waiting for a donor kidney in the United States alone. The current system faces significant challenges, including a shortage of donor organs, the risk of rejection, and the need for lifelong immunosuppressant medications.

3D printed kidneys offer a promising solution to these challenges, potentially revolutionizing the way we treat kidney failure.

Bioprinting Kidneys: A Step-by-Step Process

Vital3D’s bioprinting process involves layering biocompatible materials, such as cells, bioinks, and growth factors, to create functional kidney tissues. This process mimics the natural development of kidneys, using a 3D printer to deposit these materials layer by layer, creating a structure that resembles the complex architecture of a real kidney.

“Vital3D’s bioprinting technology uses a unique combination of biomaterials and bioprinting techniques to create functional kidney tissues that can be used for transplantation.”

Vital3D Website

The process begins with the isolation of cells from a patient’s own body, which are then grown and expanded in the lab. These cells are then incorporated into a bioink, a gel-like material that provides the structural support for the printed kidney.

The bioink is then deposited layer by layer by the 3D printer, forming the intricate network of tubules, blood vessels, and other structures found in a real kidney. Once the kidney is printed, it is placed in a bioreactor, a device that provides the necessary nutrients and oxygen for the cells to grow and mature.

Discover more by delving into artificial leaf cars sun fuel further.

The Potential Benefits of 3D Printed Kidneys

The potential benefits of 3D printed kidneys are significant, including:

- Reduced waiting times for transplantation:The current shortage of donor organs means that many patients wait years for a kidney transplant. 3D printed kidneys could potentially provide a readily available source of organs, reducing waiting times and saving lives.

- Personalized medicine:3D printed kidneys could be tailored to each patient’s specific needs, using their own cells and genetic information. This personalized approach could reduce the risk of rejection and improve the long-term success of the transplant.

- Reduced need for immunosuppressant medications:3D printed kidneys made from a patient’s own cells could reduce the need for lifelong immunosuppressant medications, which can have significant side effects. This could improve the quality of life for patients after transplantation.

The Science Behind Bioprinting

Bioprinting, a revolutionary technology at the forefront of regenerative medicine, harnesses the power of 3D printing to create functional tissues and organs. This process involves meticulously layering biocompatible materials, often containing living cells, to construct intricate 3D structures that mimic the architecture and function of natural tissues.

Biocompatible Materials

Biocompatible materials are essential for bioprinting, as they must be compatible with living cells and the body’s environment. These materials, often referred to as bioinks, provide the structural framework for the printed tissues. The ideal bioink should possess several key properties:

- Biocompatibility:The material should not elicit an adverse immune response or toxic effects in the body.

- Printability:The bioink should be printable, meaning it can be extruded through a nozzle without clogging or losing its structural integrity.

- Cell Viability:The material should support cell survival and proliferation, providing a suitable environment for cells to thrive.

- Degradability:The bioink should be biodegradable, allowing the printed tissue to be gradually replaced by natural tissue as it heals.

Cell Encapsulation

Bioprinting involves carefully encapsulating living cells within the bioink, ensuring their survival and proper function. This process requires precise control over the bioink’s properties to create an environment that supports cell growth and differentiation. The bioink should provide:

- Mechanical Support:The bioink must provide structural support for the cells, preventing them from being damaged during printing or after implantation.

- Nutrient and Oxygen Diffusion:The bioink should allow for the diffusion of nutrients and oxygen to the cells, ensuring their survival and proper functioning.

- Waste Removal:The bioink should facilitate the removal of cellular waste products, preventing the accumulation of toxins that could harm the cells.

Vascularization

Vascularization, the formation of blood vessels within the printed tissue, is crucial for long-term organ viability. Without a vascular network, the cells in the printed tissue will quickly die due to lack of oxygen and nutrients. Bioprinting techniques are being developed to incorporate vascular networks within the printed structures.

- Microfluidic Channels:Bioprinting techniques can create intricate microfluidic channels within the printed tissue, mimicking the structure of blood vessels. These channels can be infused with endothelial cells, which line blood vessels, to promote vascularization.

- Biodegradable Scaffolds:Biodegradable scaffolds with interconnected pores can be used to create a porous structure that allows for the ingrowth of blood vessels from the surrounding tissue.

- Cell-Based Strategies:Certain cell types, such as endothelial progenitor cells, can be incorporated into the bioink to promote vascularization. These cells can differentiate into endothelial cells and form new blood vessels within the printed tissue.

Cell Viability and Differentiation

Maintaining cell viability and promoting differentiation are essential for the successful bioprinting of functional organs. Cells must be able to survive the printing process and remain viable within the bioink, and they must differentiate into the specific cell types required for the desired organ function.

- Bioink Optimization:The bioink composition and printing parameters must be carefully optimized to ensure cell viability and differentiation. Factors such as the bioink’s viscosity, printing speed, and temperature can significantly affect cell survival.

- Growth Factors and Biosignals:The bioink can be supplemented with growth factors and other biosignals to stimulate cell differentiation and promote the formation of specific tissues.

- Cell Culture Techniques:Advanced cell culture techniques can be used to pre-differentiate cells before bioprinting, increasing the efficiency of the process and ensuring the formation of the desired tissue types.

The Future of Kidney Bioprinting

The development of Vital3D’s bioprinting technology for kidneys is not just a scientific breakthrough but a promise of a future where organ transplantation is no longer limited by donor availability. This technology has the potential to revolutionize healthcare and offer hope to millions suffering from kidney failure.

Potential Applications and Future Directions

The technology’s potential applications extend beyond treating kidney failure. The ability to bioprint organs could be used to:

- Develop personalized medicine:Bioprinting allows for the creation of organs tailored to the specific needs of each patient, potentially leading to better outcomes and reduced rejection rates.

- Test new drugs and therapies:Bioprinted organs could serve as a platform for testing new drugs and therapies, reducing the need for animal testing and providing more accurate results.

- Advance research on organ development and disease:Bioprinted organs could be used to study organ development and disease progression, leading to new discoveries and treatments.

The future directions for Vital3D’s technology include:

- Improving the complexity and functionality of bioprinted organs:Researchers are working on creating more complex and functional bioprinted organs, including vascularization and integration of different cell types.

- Developing new bioprinting materials and techniques:The development of new bioprinting materials and techniques could lead to more realistic and functional organs.

- Integrating bioprinting with other technologies:Combining bioprinting with other technologies, such as gene editing and artificial intelligence, could further enhance the potential of this technology.

Ethical Considerations and Regulatory Challenges

While the potential of bioprinted organs is immense, ethical considerations and regulatory challenges need to be addressed.

- Access and equity:Ensuring equitable access to this technology for all patients is crucial. The cost of bioprinting could be a barrier for some, and efforts to make it affordable and accessible are needed.

- Safety and efficacy:Rigorous testing and clinical trials are necessary to ensure the safety and efficacy of bioprinted organs before they can be used in patients.

- Ethical considerations surrounding organ creation:Questions arise about the ethical implications of creating organs from human cells and the potential for misuse of this technology.

Timeline for Clinical Applications, Vital3d 3d printed organs bioprinting kidney

It’s crucial to understand that the timeline for clinical applications of bioprinted kidneys is complex and depends on various factors, including scientific advancements, regulatory approvals, and funding. However, based on current research and development progress, a potential timeline could look like this:

- Pre-clinical testing:Vital3D is currently conducting pre-clinical testing of its bioprinted kidneys in animal models. This phase aims to evaluate the safety and efficacy of the technology and optimize the bioprinting process.

- Clinical trials:Once pre-clinical testing is successful, the next step is to conduct clinical trials in human patients. These trials will assess the safety, efficacy, and long-term outcomes of bioprinted kidneys in humans.

- Regulatory approval:After successful clinical trials, the bioprinted kidney will need to undergo regulatory review and approval by agencies like the FDA in the United States. This process involves rigorous evaluation of the technology’s safety, efficacy, and manufacturing standards.

- Market availability:Once regulatory approval is obtained, bioprinted kidneys could become available for patients in need. The widespread adoption of this technology will depend on factors like cost, accessibility, and public acceptance.