Uncommon bags 28 million scale lab grown meat rna technology – Uncommon bags, 28 million scale lab-grown meat, RNA technology – these seemingly disparate elements are converging to shape the future of food. Imagine a world where meat is grown in labs, packaged in eco-friendly, innovative bags, and reaches your table with minimal environmental impact.

This is the future we’re moving towards, a future where sustainability and innovation go hand in hand.

This exciting new landscape is driven by a growing demand for sustainable and ethical food solutions. Consumers are increasingly aware of the environmental and ethical implications of traditional meat production, leading to a surge in interest in alternative protein sources.

Lab-grown meat, with its potential to reduce land use, greenhouse gas emissions, and animal suffering, is poised to play a significant role in meeting this demand.

The Rise of Uncommon Bags: Uncommon Bags 28 Million Scale Lab Grown Meat Rna Technology

The world of bags is undergoing a transformation, moving beyond traditional materials and designs to embrace a new wave of innovation and sustainability. This shift towards uncommon bags reflects a growing awareness of environmental concerns and a desire for unique, ethically produced products.

Unconventional Bag Materials

The materials used to create bags are becoming increasingly diverse, reflecting a conscious effort to reduce reliance on conventional materials like leather and synthetic fabrics. This trend is driven by environmental concerns, ethical considerations, and a desire for unique and durable products.

- Recycled Materials:Repurposing discarded materials, such as plastic bottles, old tires, and even coffee grounds, into bags is gaining traction. This approach minimizes waste and reduces the environmental footprint of bag production. For example, companies like Freitagare known for their bags made from recycled truck tarpaulins, showcasing the potential of upcycled materials.

- Plant-Based Materials:Biodegradable and renewable plant-based materials like cork, hemp, and bamboo are increasingly popular choices for bag production. These materials offer a sustainable alternative to leather and synthetic fabrics, providing a natural and eco-friendly option. For example, Corkoruses cork, a naturally renewable material, to create stylish and durable bags.

- Innovative Textiles:Advancements in textile technology are leading to the development of innovative materials for bags, such as recycled polyester made from plastic bottles and bio-based fabrics derived from plants. These materials offer improved durability, water resistance, and sustainability compared to traditional fabrics.

For example, Patagoniautilizes recycled polyester in many of their bags, contributing to a circular economy and reducing reliance on virgin materials.

Environmental and Ethical Considerations

The rise of uncommon bags is driven by a growing awareness of the environmental and ethical impacts of traditional bag production. Consumers are increasingly seeking products that are sustainable, ethically sourced, and minimize their environmental footprint.

In this topic, you find that can data driven research show how to be happy is very useful.

“The future of fashion is sustainable fashion.”

Stella McCartney

- Reduced Environmental Impact:Uncommon bags often utilize recycled materials, plant-based alternatives, and innovative textiles that reduce the reliance on fossil fuels and minimize pollution. By choosing these bags, consumers contribute to a more sustainable future.

- Ethical Sourcing:The shift towards uncommon bags often involves a focus on ethical sourcing and fair labor practices. This ensures that the materials used in bag production are obtained responsibly and that workers are treated fairly.

- Durability and Longevity:Many uncommon bags are designed to be durable and long-lasting, reducing the need for frequent replacements and minimizing waste. This approach promotes a more sustainable consumption model.

The 28 Million Scale of Lab-Grown Meat

The recent announcement of a 28 million scale production facility for lab-grown meat signifies a significant milestone in the development of this emerging industry. This scale represents a substantial leap forward in the ability to produce cultivated meat on an industrial level, bringing it closer to mainstream adoption and potentially revolutionizing the food system.

The Significance of 28 Million Scale Production

The 28 million scale signifies a major shift in the production capacity of lab-grown meat. This scale represents a significant increase compared to current production levels, demonstrating the rapid advancements in technology and the growing investment in this sector. This scale allows for economies of scale, reducing production costs and making lab-grown meat more accessible to consumers.

The Potential of Lab-Grown Meat to Address Food Security and Sustainability Challenges

Lab-grown meat has the potential to address several critical challenges related to food security and sustainability.

- Food Security:Lab-grown meat can provide a reliable and sustainable source of protein, especially in regions facing food insecurity. Its production is not limited by land, water, or weather constraints, making it a more resilient option compared to traditional livestock farming.

- Sustainability:Lab-grown meat production significantly reduces the environmental footprint associated with conventional meat production. It requires less land, water, and energy, resulting in lower greenhouse gas emissions and a reduced impact on biodiversity.

- Animal Welfare:Lab-grown meat eliminates the ethical concerns associated with animal agriculture, as it does not involve the slaughter of animals.

Economic and Environmental Factors Influencing the Growth of the Lab-Grown Meat Industry

Several economic and environmental factors are driving the growth of the lab-grown meat industry.

- Consumer Demand:Increasing awareness of the environmental and ethical impacts of traditional meat production is driving consumer demand for alternative protein sources. Lab-grown meat offers a compelling option for environmentally conscious consumers.

- Technological Advancements:Continuous improvements in cell culture technology and bioengineering are reducing production costs and enhancing the quality and taste of lab-grown meat.

- Government Support:Governments worldwide are recognizing the potential of lab-grown meat to address food security and sustainability challenges. They are providing funding and policy support to foster the growth of this industry.

- Investment:Venture capitalists and investors are increasingly pouring money into lab-grown meat companies, recognizing the immense growth potential of this sector.

RNA Technology

RNA technology is revolutionizing the world of lab-grown meat production, offering a powerful tool to manipulate and enhance meat cells for a more efficient and sustainable future. This technology plays a crucial role in the development of lab-grown meat, enabling the production of meat products that are not only environmentally friendly but also more affordable and accessible to a wider audience.

RNA Technology’s Role in Lab-Grown Meat Production

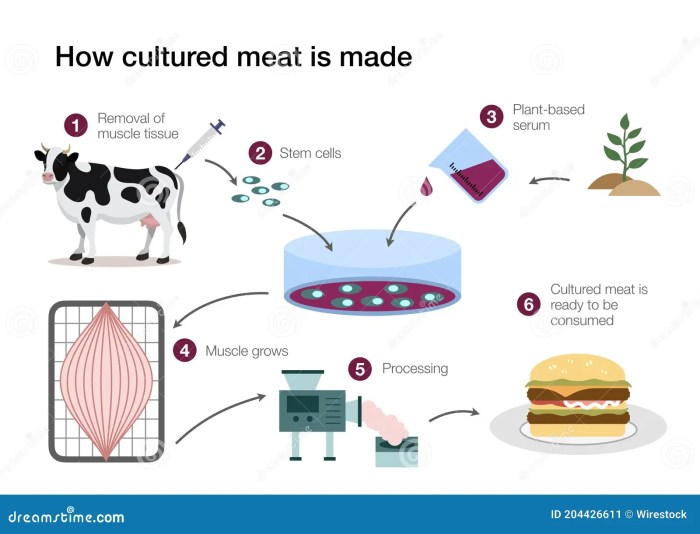

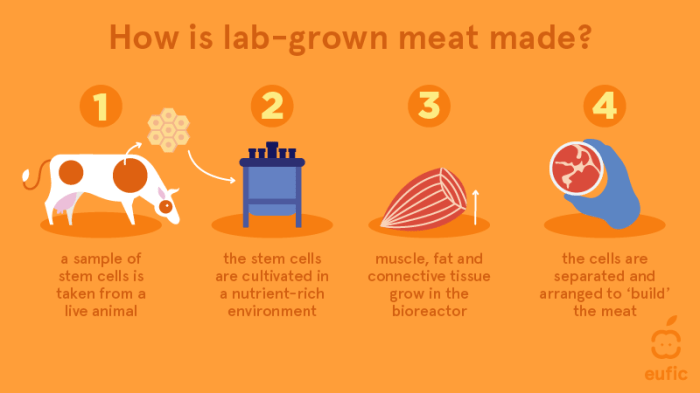

RNA technology is instrumental in the development of lab-grown meat. It provides a mechanism for manipulating and enhancing the growth and development of meat cells, ultimately influencing the quality and characteristics of the final product. The process of using RNA in lab-grown meat production involves several key steps:

Manipulating Cell Growth and Differentiation

RNA technology allows scientists to manipulate the genetic expression of meat cells, influencing their growth and differentiation. This is achieved through the use of specific RNA molecules, such as messenger RNA (mRNA), which can deliver instructions to cells to produce specific proteins.

For example, scientists can introduce mRNA molecules that code for proteins that promote muscle growth, leading to the development of larger and more meaty cell cultures.

Enhancing Meat Quality

RNA technology can also be used to enhance the quality of lab-grown meat by influencing the expression of genes responsible for meat texture, flavor, and nutritional content. This includes targeting genes involved in fat deposition, muscle fiber composition, and the production of specific flavor compounds.

Addressing Ethical Concerns

RNA technology can also address ethical concerns surrounding traditional meat production. For instance, it can be used to develop meat products that are free from antibiotics and hormones, reducing the need for these substances in animal agriculture.

Benefits of RNA Technology in Lab-Grown Meat Production, Uncommon bags 28 million scale lab grown meat rna technology

RNA technology offers several potential benefits for lab-grown meat production, including:

Increased Efficiency and Sustainability

RNA technology can significantly increase the efficiency of lab-grown meat production by enhancing cell growth and differentiation, leading to higher yields and faster production times. This can contribute to a more sustainable food system by reducing the environmental impact of traditional meat production.

Improved Meat Quality

RNA technology allows for the production of lab-grown meat with desirable qualities, such as improved texture, flavor, and nutritional content. This can enhance the appeal and desirability of lab-grown meat products, making them more competitive with traditional meat.

Enhanced Food Security

RNA technology can contribute to enhanced food security by providing a more sustainable and reliable source of protein. This is particularly important in regions facing food shortages and challenges related to traditional meat production.

Challenges of RNA Technology in Lab-Grown Meat Production

While RNA technology holds immense promise for lab-grown meat production, it also presents several challenges that need to be addressed:

Regulatory Approval and Public Acceptance

The use of RNA technology in food production requires rigorous regulatory approval and public acceptance. Addressing concerns about the safety and ethical implications of RNA-modified food products is crucial for widespread adoption of this technology.

Cost and Scalability

RNA technology can be expensive, particularly for large-scale production. Developing cost-effective and scalable RNA-based solutions for lab-grown meat production is essential for making this technology commercially viable.

Technical Advancements

Further technical advancements are needed to optimize the use of RNA technology in lab-grown meat production. This includes developing more efficient and targeted RNA delivery systems and improving our understanding of the complex interactions between RNA and meat cells.

The Intersection of Uncommon Bags and Lab-Grown Meat

The rise of lab-grown meat presents a unique opportunity for the packaging industry to innovate and develop sustainable solutions. Uncommon bag materials, with their diverse properties and environmental benefits, can play a crucial role in creating packaging that meets the specific needs of this emerging food sector.

Designing Sustainable Packaging Solutions for Lab-Grown Meat

The packaging of lab-grown meat requires careful consideration due to its delicate nature and the need to maintain freshness and quality. Uncommon bag materials can offer a sustainable and innovative approach to packaging this new food source.

- Biodegradable and Compostable Materials:Materials like polylactic acid (PLA) and bioplastics derived from plant sources can provide a sustainable alternative to traditional plastic packaging. These materials can decompose in landfills or compost bins, reducing plastic waste and environmental impact.

- Edible Films and Coatings:Edible films made from proteins, carbohydrates, or lipids can serve as a protective barrier for lab-grown meat, eliminating the need for separate packaging materials. These films can be incorporated directly into the product, reducing waste and offering a unique consumer experience.

- Seaweed-Based Packaging:Seaweed-derived materials are gaining traction as a sustainable and biodegradable packaging option. These materials can provide excellent barrier properties and can be easily composted, making them ideal for lab-grown meat packaging.

Benefits and Challenges of Using Unconventional Materials

The use of unconventional materials in lab-grown meat packaging presents both benefits and challenges.

- Benefits:

- Sustainability:Uncommon bag materials often have a lower environmental footprint than traditional plastics, reducing waste and greenhouse gas emissions.

- Biodegradability:Many unconventional materials are biodegradable, making them a more sustainable choice for packaging.

- Innovation:The use of uncommon materials allows for the development of innovative packaging solutions that enhance the consumer experience and improve product shelf life.

- Challenges:

- Cost:Unconventional materials can sometimes be more expensive than traditional plastics, requiring a higher initial investment.

- Scalability:Scaling up the production of uncommon bag materials to meet the demands of the lab-grown meat industry can be a challenge.

- Consumer Perception:Consumers may be unfamiliar with unconventional materials and may require education about their benefits and safety.