Uk startup space dots wants to test space materials well in space – UK Startup Space Dots Tests Space Materials in Space, aiming to revolutionize how we design and build spacecraft. This ambitious startup is tackling the challenges of testing materials in the harsh environment of space, where simulating Earth-bound conditions simply isn’t enough.

Space Dots believes that understanding how materials behave in the vacuum of space, with its extreme temperatures and radiation, is crucial for building reliable and safe spacecraft for future exploration.

Their unique approach involves sending small, specialized “dots” into space, equipped with sensors to measure the performance of different materials under real-world conditions. This innovative method allows for more accurate data collection and analysis, leading to breakthroughs in material science and ultimately contributing to safer and more efficient spacecraft design.

UK Startup Space Dots

Space Dots, a UK-based startup, is making waves in the space industry by offering a unique solution for testing materials in the harsh environment of space. Their mission is to revolutionize the way materials are tested for space applications, providing crucial data for the development of future spacecraft, satellites, and other space-bound technologies.

Space Dots’ Approach to Space Material Testing

Space Dots utilizes a novel approach to space material testing, employing small, specialized “dots” equipped with sensors that are attached to materials or structures. These dots are designed to withstand the extreme conditions of space, including radiation, vacuum, and temperature fluctuations.

They can then be deployed in orbit on satellites or spacecraft, where they collect valuable data on the performance of the materials being tested.

The Unique Value Proposition of Space Dots

Space Dots’ approach offers several advantages over traditional methods of space material testing.

- Cost-Effectiveness:Space Dots’ small size and modular design make them significantly more affordable to deploy and operate compared to larger, dedicated space-based testing facilities. This makes space material testing accessible to a wider range of organizations, including smaller startups and research institutions.

- Flexibility and Scalability:Space Dots can be easily customized to meet the specific needs of different testing scenarios. They can be deployed in various configurations, allowing for a wide range of material properties and environmental conditions to be studied. Additionally, the number of dots can be scaled up or down depending on the complexity of the test.

- Real-Time Data Collection:Space Dots transmit data in real-time, allowing researchers to monitor the performance of materials and structures in orbit. This provides valuable insights into the long-term behavior of materials in space, which is crucial for optimizing spacecraft design and extending mission lifespans.

Examples of Space Dots Applications

Space Dots can be used for a wide range of applications, including:

- Testing the durability of spacecraft materials:Space Dots can be attached to spacecraft components to monitor their performance in the harsh space environment. This data can help engineers design more resilient and long-lasting spacecraft.

- Evaluating the effectiveness of radiation shielding:Space Dots can be used to measure the amount of radiation exposure experienced by spacecraft materials. This information is crucial for developing effective radiation shielding strategies for future missions.

- Studying the behavior of materials in microgravity:Space Dots can be used to study the behavior of materials in the microgravity environment of space. This data can help scientists develop new materials and technologies for space exploration.

Space Dots’ Impact on the Space Industry

Space Dots has the potential to significantly impact the space industry by making space material testing more accessible, affordable, and efficient. Their innovative approach is poised to accelerate the development of new space technologies and contribute to the advancement of space exploration.

The Importance of Testing Space Materials in Space

Designing spacecraft to withstand the harsh conditions of space requires rigorous testing to ensure their reliability and safety. While ground-based simulations can provide valuable insights, they cannot fully replicate the unique environment of space. This is where space material testing comes into play, offering a crucial advantage in understanding how materials behave under actual space conditions.

Challenges of Simulating Space Conditions on Earth

Simulating space conditions on Earth is a complex and challenging task. Although advanced laboratories can recreate some aspects of space, like vacuum and extreme temperatures, replicating the full spectrum of space environment is impossible.

Further details about 5 top tips to land your dream tech job in is accessible to provide you additional insights.

- Microgravity:One of the most significant challenges is simulating microgravity. On Earth, materials are constantly subjected to gravitational forces, affecting their behavior and properties. Creating a microgravity environment for extended periods is extremely difficult and expensive.

- Radiation:Space is filled with various forms of radiation, including cosmic rays and solar flares. These high-energy particles can damage materials and electronics, causing degradation and malfunctions. Replicating the full spectrum of space radiation on Earth is a significant technical hurdle.

- Atomic Oxygen:Atomic oxygen is a highly reactive element present in low Earth orbit. It can erode and degrade materials, particularly polymers and composites. Creating a controlled environment with atomic oxygen levels similar to those found in space is a complex and expensive undertaking.

Why Testing Materials in Space is Crucial

Testing materials in space is crucial for several reasons.

- Accurate Material Behavior:Space material testing provides a realistic assessment of how materials behave under actual space conditions. This information is critical for selecting the right materials for spacecraft components, ensuring their long-term performance and reliability.

- Safe Spacecraft Design:Understanding how materials react to the space environment is essential for designing safe and reliable spacecraft. Space material testing helps identify potential weaknesses and vulnerabilities, enabling engineers to make informed design decisions and mitigate risks.

- Spacecraft Performance Optimization:Testing materials in space can lead to breakthroughs in spacecraft development. By understanding the behavior of materials in a real-world setting, engineers can optimize spacecraft performance, reducing weight, increasing efficiency, and extending mission life.

Examples of Space Material Testing Breakthroughs

Space material testing has led to significant advancements in spacecraft development.

- Development of Radiation-Resistant Materials:Testing materials in space has helped develop radiation-resistant materials, crucial for protecting sensitive electronics and components from cosmic rays and solar flares. These materials are used in spacecraft systems, satellites, and even medical devices.

- Improved Thermal Control Systems:Space material testing has led to advancements in thermal control systems, which are vital for regulating spacecraft temperatures. By understanding how materials react to extreme temperature variations, engineers can design more efficient and reliable thermal control systems.

- Development of Advanced Composites:Space material testing has played a crucial role in the development of advanced composites, which are lightweight, strong, and resistant to harsh environments. These materials are used in spacecraft structures, solar panels, and other components.

Space Dots’ Technology and Methodology

Space Dots’ approach to testing space materials in space is a combination of innovative technology and carefully designed experimental procedures. They leverage a variety of techniques to expose materials to the harsh conditions of space and analyze their performance.

Experimental Setup and Procedures

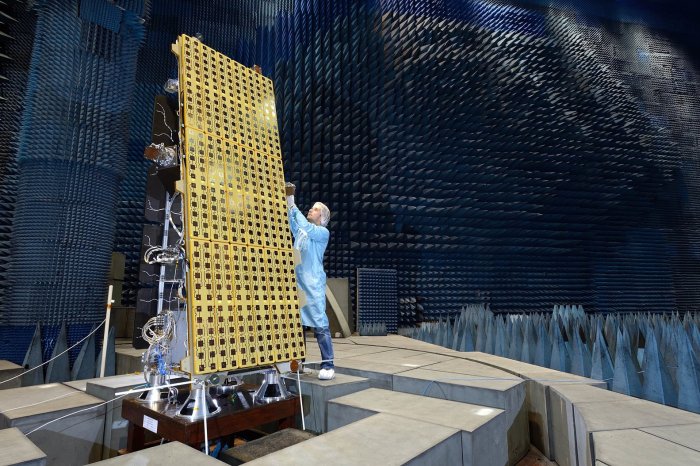

Space Dots’ experimental setup involves a unique platform that is deployed into low Earth orbit. This platform is equipped with specialized instruments and chambers designed to simulate the extreme conditions of space, such as vacuum, radiation, and temperature fluctuations. The platform is capable of holding various material samples and exposing them to these conditions for extended periods.The testing procedures involve carefully selecting and preparing the materials to be tested.

These materials are then mounted within the experimental chambers on the platform. Once in orbit, the platform’s instruments are activated to expose the materials to the desired space environment.

Data Collection and Analysis Methods

Space Dots employs a range of sensors and data acquisition systems to collect real-time data on the materials’ performance during the tests. These sensors monitor parameters such as temperature, pressure, radiation levels, and material properties like tensile strength and elasticity.The collected data is transmitted back to Earth for analysis.

Space Dots uses advanced algorithms and statistical methods to analyze the data, identify trends, and draw conclusions about the materials’ behavior in space. This analysis helps to determine the materials’ suitability for specific space applications and to understand their long-term durability.

Key Technologies Employed by Space Dots

- Miniaturized Sensors:Space Dots utilizes miniaturized sensors to collect data on various environmental parameters and material properties. These sensors are designed to be lightweight and low-power, making them ideal for deployment on small satellites or CubeSats.

- High-Throughput Material Testing:Space Dots has developed a high-throughput material testing system that allows for the simultaneous testing of multiple materials in different environments. This allows for efficient and comprehensive material evaluation.

- Data Transmission and Analysis:Space Dots utilizes advanced data transmission and analysis techniques to ensure the reliable collection and processing of data from its space-based experiments. This includes using ground stations and specialized software to analyze the data.

Potential Applications of Space Dots’ Research: Uk Startup Space Dots Wants To Test Space Materials Well In Space

Space Dots’ groundbreaking research on testing materials in the harsh conditions of space holds immense potential to revolutionize various aspects of the space industry. By understanding how materials behave in the vacuum of space, extreme temperatures, and radiation, Space Dots can contribute significantly to advancements in satellite design, space exploration, and space infrastructure development.

Applications in Satellite Design

The findings from Space Dots’ research can directly impact the design of more robust and reliable satellites. Satellites are exposed to a multitude of harsh conditions in space, including extreme temperature fluctuations, micrometeoroid impacts, and radiation. By testing materials in space, Space Dots can identify materials that are best suited for specific applications, such as:

- Solar panels:Space Dots’ research can lead to the development of more efficient and durable solar panels that can withstand the rigors of space and provide reliable power for extended periods. This is crucial for spacecraft and satellites that rely on solar energy for their operations.

- Structural components:Space Dots’ research can contribute to the design of lighter, stronger, and more resilient structural components for satellites. This can lead to more efficient satellite designs with improved performance and longer operational lifespans.

- Thermal shielding:Space Dots’ research can help in developing advanced thermal shielding materials that can protect sensitive electronic components from extreme temperature fluctuations in space. This is essential for ensuring the proper functioning of satellites in various orbits.

Applications in Space Exploration

Space Dots’ research has significant implications for future space exploration missions. Understanding how materials behave in the harsh environment of space is crucial for designing spacecraft and equipment that can withstand the challenges of deep space travel. Some key applications include:

- Spacecraft construction:Space Dots’ research can inform the development of new materials and construction techniques for spacecraft that are lightweight, durable, and resistant to radiation damage. This is essential for long-duration missions to distant planets or asteroids.

- Habitable structures:Space Dots’ research can play a vital role in designing habitable structures for future space missions, such as lunar or Martian outposts. By testing materials in space, researchers can identify materials that are suitable for creating airtight, radiation-shielded, and sustainable living environments.

- Space suit development:Space Dots’ research can contribute to the development of advanced space suits that provide better protection from the hazards of space, such as micrometeoroid impacts and extreme temperature fluctuations. This is crucial for astronauts working outside the spacecraft during spacewalks or exploration activities.

Applications in Space Infrastructure Development

Space Dots’ research can also contribute to the development of a robust and sustainable space infrastructure. This includes the construction of space stations, lunar bases, and other space-based facilities. Some key applications include:

- Space station modules:Space Dots’ research can lead to the development of more durable and reliable modules for space stations, providing a safe and sustainable living and working environment for astronauts. This includes the development of materials that can withstand the harsh conditions of space and provide protection from radiation and micrometeoroid impacts.

- Space-based infrastructure:Space Dots’ research can be applied to the development of new materials and technologies for constructing space-based infrastructure, such as solar power stations, space telescopes, and communication satellites. This can lead to more efficient and cost-effective construction of space-based infrastructure.

- Space debris mitigation:Space Dots’ research can contribute to the development of new materials and technologies for mitigating space debris. This includes the development of materials that can withstand the high-velocity impacts of space debris and technologies for removing debris from orbit.

Applications in Specific Industries

Space Dots’ research has the potential to benefit various industries beyond space exploration. Some key examples include:

- Aerospace:Space Dots’ research can lead to the development of lighter, stronger, and more durable materials for aircraft and other aerospace applications. This can improve fuel efficiency, reduce maintenance costs, and enhance safety.

- Telecommunications:Space Dots’ research can contribute to the development of more reliable and efficient satellite communication systems. This can improve global connectivity and enable the development of new applications, such as high-speed internet access in remote areas.

- Energy:Space Dots’ research can lead to the development of new materials and technologies for solar energy generation and storage. This can contribute to a more sustainable energy future and reduce reliance on fossil fuels.

Challenges and Future Directions for Space Dots

Space Dots faces a multitude of challenges in its ambitious mission to test space materials in the harsh environment of space. These challenges range from technical hurdles to the financial and logistical complexities of operating in a demanding and unforgiving environment.

Technical Challenges

The technical challenges facing Space Dots are numerous and complex. One of the most significant challenges is the need to develop and deploy highly sensitive and robust instruments capable of accurately measuring the effects of space radiation, extreme temperatures, and micrometeoroid impacts on materials.

These instruments must be compact, lightweight, and energy-efficient to be viable for deployment on satellites or other space-based platforms.

- Developing Reliable Sensors:Designing sensors that can withstand the harsh space environment and provide accurate data on material degradation is a significant challenge. The sensors must be capable of measuring various parameters, such as radiation levels, temperature fluctuations, and material changes, while operating in extreme conditions.

- Minimizing Instrument Size and Weight:Spacecraft have limited payload capacity, making it essential to minimize the size and weight of the instruments used for material testing. This requires innovative engineering solutions to develop compact and lightweight sensors and data processing units.

- Data Transmission and Analysis:The data collected by the instruments must be transmitted back to Earth for analysis. This requires reliable communication systems and sophisticated data analysis techniques to extract meaningful insights from the collected data.

Financial and Logistical Challenges, Uk startup space dots wants to test space materials well in space

The financial and logistical aspects of space exploration are equally demanding. Launching and maintaining a satellite in orbit is an expensive endeavor, requiring significant investment and meticulous planning. Space Dots must secure funding for research and development, manufacturing, launch, and ongoing operations.

- Funding for Research and Development:Space Dots requires substantial funding for its research and development efforts, including designing, building, and testing its instruments and platforms.

- Launch Costs:Launching a satellite into space is a costly process, with launch providers charging millions of dollars for each mission. Space Dots must secure funding or partnerships to cover these launch costs.

- Satellite Maintenance and Operations:Once in orbit, satellites require ongoing maintenance and operations, including communication, data downlink, and potentially repairs or upgrades. These activities add to the overall cost of the mission.

Future Directions for Space Dots

Despite the challenges, Space Dots has a bright future. The company is poised to play a pivotal role in advancing our understanding of materials in space and paving the way for future space exploration. Space Dots can expand its research and development efforts in several key areas:

- Expanding the Range of Materials Tested:Space Dots can expand its testing capabilities to encompass a wider range of materials, including advanced composites, ceramics, and novel alloys, which are crucial for future space missions.

- Developing New Testing Methods:The company can invest in developing new and innovative testing methods, such as in-situ material synthesis and characterization, to further enhance its research capabilities.

- Partnering with Space Agencies and Industry:Collaborating with space agencies, such as the European Space Agency (ESA) and NASA, and industry partners can provide access to valuable resources, expertise, and funding.

- Developing Commercial Applications:Space Dots can explore commercial applications for its research, such as providing data and insights to manufacturers of space-based materials and components.