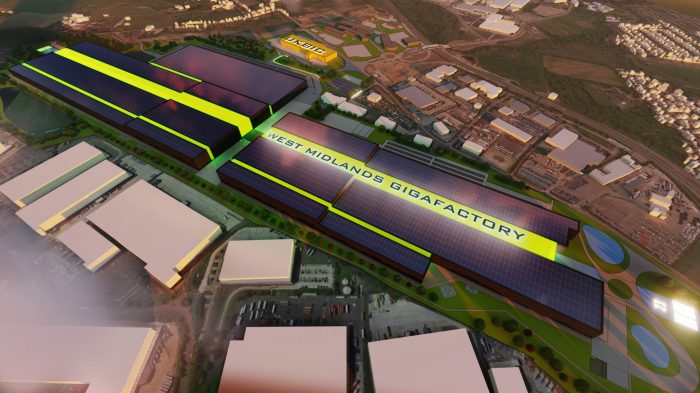

Plan to build uks first battery gigafactory out of british hands – Plan to Build UK’s First Battery Gigafactory Out of British Hands – a bold statement, a call to action, and a potential game-changer for the UK’s automotive industry. The UK’s reliance on foreign battery manufacturers has become a point of concern, with the potential to hinder the growth of its electric vehicle sector.

This plan aims to address this vulnerability by creating a domestic battery production powerhouse, ensuring a secure and sustainable future for the UK’s electric vehicle industry.

The plan Artikels a comprehensive strategy to establish a UK-owned battery gigafactory, addressing the challenges and opportunities that lie ahead. It delves into the economic and strategic implications, the technological advancements required, the environmental considerations, and the crucial role of public engagement.

This ambitious project promises to create thousands of jobs, attract significant investment, and bolster the UK’s position as a global leader in electric vehicle technology.

The UK’s Battery Gigafactory Landscape

The UK is aiming to become a global leader in the electric vehicle (EV) industry, but its reliance on foreign battery manufacturers poses a significant challenge. The country currently lacks a large-scale battery gigafactory, which is crucial for meeting the growing demand for EV batteries.

However, recent government initiatives and private investments are beginning to address this gap, paving the way for a more robust domestic battery production ecosystem.

Current State of Battery Gigafactories in the UK

The UK currently has a limited number of battery gigafactories. The most notable example is the Britishvolt facility in Blyth, Northumberland, which is under construction and aims to produce battery cells for electric vehicles. Other existing facilities include the Williams Advanced Engineering facility in Oxfordshire, which focuses on battery pack assembly and development, and the Faraday Institution, a research center dedicated to battery technology.

The UK’s Reliance on Foreign Battery Manufacturers

The UK’s automotive industry is heavily reliant on foreign battery manufacturers. Currently, most EV batteries used in the UK are imported from countries like China, South Korea, and Japan. This dependence on foreign suppliers raises concerns about supply chain vulnerabilities, potential price fluctuations, and a lack of control over battery technology.

Government Policies and Initiatives for Domestic Battery Production

The UK government has recognized the importance of developing a domestic battery production industry. In recent years, it has implemented several policies and initiatives aimed at boosting battery production, including:

- The Faraday Institution: The Faraday Institution is a research center dedicated to battery technology. It receives government funding and collaborates with industry partners to develop innovative battery technologies and support the UK’s battery ecosystem.

- The Automotive Transformation Fund: The Automotive Transformation Fund provides financial support to companies developing and manufacturing electric vehicles and battery technologies in the UK. The fund aims to attract investment and accelerate the development of the UK’s EV industry.

- The Battery Industrial Strategy: The Battery Industrial Strategy Artikels the UK government’s long-term vision for developing a thriving battery industry. It includes plans for supporting research and development, attracting investment, and creating a skilled workforce in the battery sector.

Economic and Strategic Implications

The establishment of a UK-owned battery gigafactory holds significant economic and strategic implications for the UK, impacting its automotive industry, energy sector, and overall economic competitiveness. A domestically owned gigafactory would foster innovation, create high-skilled jobs, and secure the UK’s position as a global leader in electric vehicle (EV) technology.

Economic Benefits of a UK-Owned Gigafactory

The economic benefits of a UK-owned battery gigafactory are substantial and far-reaching. A gigafactory would stimulate investment, create jobs, and bolster the UK’s supply chain resilience.

- Job Creation:A gigafactory would create thousands of highly skilled jobs in manufacturing, engineering, research and development, and logistics. These jobs would be distributed across various regions, contributing to regional economic growth and revitalizing local communities.

- Investment and Economic Growth:The construction and operation of a gigafactory would attract significant private and public investment, boosting the UK’s overall economic output. This investment would also stimulate growth in related industries, such as materials processing, component manufacturing, and recycling.

- Supply Chain Security:A UK-owned gigafactory would ensure a secure and reliable supply of batteries for the UK’s growing EV industry. This would reduce the UK’s dependence on foreign suppliers, mitigating potential supply chain disruptions and geopolitical risks.

Strategic Implications of Dependence on Foreign Battery Manufacturers, Plan to build uks first battery gigafactory out of british hands

The UK’s current reliance on foreign battery manufacturers poses significant strategic challenges. This dependence creates vulnerabilities in the UK’s EV industry, potentially impacting its competitiveness and energy security.

- Vulnerability to Supply Chain Disruptions:The UK’s reliance on foreign suppliers exposes it to potential supply chain disruptions, such as those caused by geopolitical tensions, natural disasters, or pandemics. These disruptions could lead to delays in EV production, price increases, and a loss of market share.

- Loss of Technological Leadership:The UK’s dependence on foreign battery manufacturers limits its ability to develop and control its own EV technology. This could hinder innovation and competitiveness in the global EV market.

- Energy Security Concerns:The UK’s reliance on foreign battery manufacturers raises concerns about energy security. If the UK were to rely heavily on imported batteries, it would be vulnerable to disruptions in the supply of critical minerals and materials needed for battery production.

Advantages of a UK-Owned Gigafactory

A UK-owned gigafactory offers significant economic and strategic advantages over foreign-owned alternatives.

- Control over Technology and Innovation:A UK-owned gigafactory would allow the UK to control its own battery technology, fostering innovation and developing a competitive edge in the global EV market. The UK would have the ability to direct research and development efforts toward specific needs and priorities, promoting technological advancements and establishing itself as a leader in battery technology.

You also can understand valuable knowledge by exploring dutch are world leaders in lab grown meat but cant eat it meatable.

- Job Creation and Economic Growth:A UK-owned gigafactory would generate substantial economic activity, creating high-skilled jobs and stimulating investment in related industries. This would contribute to the UK’s overall economic growth and prosperity.

- Supply Chain Resilience:A UK-owned gigafactory would ensure a secure and reliable supply of batteries for the UK’s EV industry. This would reduce the UK’s dependence on foreign suppliers, mitigating potential supply chain disruptions and geopolitical risks.

- Strategic Advantage:A UK-owned gigafactory would enhance the UK’s strategic position in the global EV market. The UK would have greater control over its own energy security and technological development, reducing its reliance on foreign actors and strengthening its position as a global leader in EV technology.

Challenges and Opportunities

Building a battery gigafactory in the UK presents both significant challenges and opportunities. While the UK has a strong automotive industry and research capabilities, overcoming the hurdles of technological expertise, funding, and infrastructure is crucial for success. The opportunities presented by the UK’s existing automotive industry and research capabilities could play a vital role in supporting battery production.

Technological Expertise

The UK’s current battery production capabilities are limited, requiring significant investment in research and development to bridge the technological gap. The development of advanced battery technologies, such as solid-state batteries, requires substantial expertise and resources. The UK can leverage its existing research institutions and universities to develop the necessary expertise.

Funding

The construction of a gigafactory requires substantial capital investment, estimated to be in the billions of pounds. Securing funding from both public and private sources is essential. Government support through grants, tax breaks, and incentives can play a vital role in attracting private investment.

Infrastructure

The UK’s infrastructure, including energy supply, transportation, and logistics, needs to be adequately developed to support a large-scale battery manufacturing facility. The UK government needs to ensure that the necessary infrastructure is in place to facilitate the efficient operation of a gigafactory.

Opportunities Presented by the UK’s Existing Automotive Industry

The UK’s automotive industry is a significant potential market for battery production. The industry is undergoing a transition to electric vehicles, creating a strong demand for battery cells. The UK’s existing automotive supply chain can be leveraged to support battery production, creating a vertically integrated ecosystem.

Opportunities Presented by the UK’s Research Capabilities

The UK has a strong track record in battery research and development. The UK’s universities and research institutions are at the forefront of innovation in battery technologies, including solid-state batteries and advanced materials. These research capabilities can be harnessed to develop and commercialize new battery technologies, giving the UK a competitive advantage in the global battery market.

Potential Partnerships and Collaborations

Partnerships and collaborations with international companies, research institutions, and universities can play a significant role in the development of a UK-owned gigafactory. Collaborations can facilitate technology transfer, knowledge sharing, and access to global markets. The UK can leverage its existing relationships with countries like Japan, South Korea, and Germany, which are leaders in battery technology.

Technology and Innovation

The UK’s ambition to establish a homegrown battery gigafactory hinges on its ability to embrace cutting-edge technologies and foster a vibrant ecosystem of innovation. This requires a multi-faceted approach, encompassing advancements in battery chemistry, cell design, manufacturing processes, and recycling technologies.

The UK’s Potential for Leadership in Battery Technology

The UK possesses a strong foundation for becoming a global leader in battery technology and research. Its world-renowned universities and research institutions, coupled with a thriving private sector, provide a fertile ground for innovation. The government’s commitment to supporting research and development in battery technologies through initiatives like the Faraday Institution and the Advanced Propulsion Centre is further bolstering the UK’s position.

Key Technologies and Innovations

The development of a competitive battery gigafactory requires a confluence of technologies and innovations.

- Battery Chemistry:Research into next-generation battery chemistries, such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries, is crucial to enhance energy density, lifespan, and safety.

- Cell Design:Innovative cell designs, including pouch cells, cylindrical cells, and prismatic cells, are being explored to optimize performance and cost-effectiveness.

- Manufacturing Processes:Advanced manufacturing processes, such as high-throughput electrode coating, automated assembly lines, and in-line quality control, are essential for achieving high production volumes and maintaining consistent quality.

- Recycling Technologies:Sustainable battery recycling technologies are critical for recovering valuable materials and minimizing environmental impact.

Examples of UK-Based Companies and Institutions Contributing to Battery Innovation

- Faraday Institution:This independent research institute focuses on battery technologies, working closely with industry and academia to accelerate the development and adoption of advanced battery technologies.

- Britishvolt:This company is building a gigafactory in the UK, aiming to produce batteries for electric vehicles and other applications.

- University of Oxford:The university’s researchers are making significant contributions to battery chemistry, particularly in the development of solid-state batteries.

- Imperial College London:Researchers at Imperial College London are developing innovative battery materials and recycling technologies.

Environmental Considerations

The construction and operation of a battery gigafactory present significant environmental implications, demanding careful consideration and mitigation strategies. This section examines the environmental impact of battery production, highlighting the potential for a UK-owned gigafactory to minimize its footprint.

Resource Extraction

The production of lithium-ion batteries, the dominant type used in electric vehicles, relies on a range of critical minerals, including lithium, cobalt, nickel, and manganese. The extraction of these minerals can have substantial environmental impacts.

- Mining operationscan lead to deforestation, habitat loss, and soil and water contamination.

- Water usagein mining processes can deplete local water resources and impact surrounding ecosystems.

- Greenhouse gas emissionsfrom mining activities contribute to climate change.

A UK-owned gigafactory can mitigate these impacts by sourcing materials from suppliers committed to sustainable mining practices. This includes supporting responsible mining initiatives, such as the Responsible Minerals Initiative (RMI), and promoting the use of recycled materials.

Manufacturing Processes

The manufacturing of battery cells involves complex chemical processes that can generate emissions and waste.

- Energy consumptionduring production is significant, requiring large amounts of electricity, which can contribute to greenhouse gas emissions if sourced from fossil fuels.

- Chemical emissionsfrom manufacturing processes can pollute the air and water, posing risks to human health and the environment.

- Waste generationfrom battery production, including scrap materials and hazardous chemicals, requires careful management and disposal.

A UK-owned gigafactory can adopt sustainable practices to minimize these impacts. This includes using renewable energy sources for power, implementing energy-efficient technologies, and minimizing waste generation through closed-loop recycling processes.

End-of-Life Disposal

Batteries have a finite lifespan and eventually require disposal. Improper disposal can lead to environmental contamination and health risks.

- Leaking batteriescan release hazardous substances into the environment, contaminating soil and water.

- Incinerationof batteries can release toxic fumes into the atmosphere.

- Landfillingof batteries can leach harmful chemicals into groundwater.

A UK-owned gigafactory can address these challenges by promoting responsible battery recycling and reuse. This includes establishing efficient collection and recycling systems, developing technologies for battery dismantling and material recovery, and promoting the use of recycled battery materials in new products.

Innovative Technologies and Approaches

The development of innovative technologies and approaches can significantly enhance the environmental sustainability of battery production.

- Solid-state batteries, which use solid electrolytes instead of liquid ones, offer potential advantages in terms of safety, energy density, and longevity. They also eliminate the need for flammable and corrosive materials, reducing the risk of environmental contamination.

- Closed-loop recyclingprocesses can recover valuable materials from end-of-life batteries, reducing reliance on virgin resources and minimizing waste.

- Renewable energy sources, such as solar and wind power, can significantly reduce the carbon footprint of battery production.

By embracing these innovations, a UK-owned gigafactory can contribute to a more sustainable battery industry and play a crucial role in the transition to a low-carbon economy.

Public Opinion and Stakeholder Engagement: Plan To Build Uks First Battery Gigafactory Out Of British Hands

The success of any major infrastructure project, particularly one as transformative as a battery gigafactory, hinges on public acceptance and support. Building a UK-owned gigafactory requires navigating a complex landscape of public perceptions, concerns, and expectations. Understanding and addressing these concerns is crucial for ensuring the project’s long-term viability and minimizing potential disruptions.

Public Perceptions and Concerns

Public perceptions surrounding battery gigafactories are often shaped by a mix of factors, including environmental concerns, economic benefits, and job security. A key concern is the potential environmental impact of the factory’s operations, including emissions, waste generation, and land use.

There are also concerns about the potential impact on local communities, such as increased traffic, noise pollution, and the potential displacement of existing businesses. However, there is also a strong recognition of the potential economic benefits of a gigafactory, including job creation, investment, and technological advancements.

Public perception is influenced by factors such as:

- Environmental Impact: Concerns about air and water pollution, waste generation, and land use are prominent. Public perception is influenced by past experiences with industrial facilities and the perceived lack of transparency in the decision-making process.

- Job Security: Concerns about the long-term viability of jobs and the potential for automation to displace workers are often voiced. This is particularly relevant in regions with high unemployment rates.

- Community Impact: Concerns about increased traffic, noise pollution, and the potential displacement of existing businesses are common. The perceived lack of consultation and engagement with local communities can further amplify these concerns.

- Economic Benefits: Public perception is also influenced by the perceived economic benefits of the project, including job creation, investment, and technological advancements. However, concerns about the potential for these benefits to accrue to a select few, rather than being widely distributed, can undermine public support.

Role of Stakeholder Engagement

Stakeholder engagement is crucial for building trust and ensuring the successful development and operation of a UK-owned gigafactory. It involves actively listening to the concerns of all stakeholders, including local communities, businesses, environmental groups, and government agencies. This engagement should be ongoing throughout the project lifecycle, from the initial planning stages to the operational phase.

Effective stakeholder engagement can help to:

- Build Trust and Transparency: Open and honest communication with stakeholders helps to build trust and transparency, which is essential for addressing concerns and building support for the project.

- Identify and Address Concerns: Active engagement with stakeholders allows for the identification and early resolution of potential concerns, reducing the risk of delays or protests.

- Develop Sustainable Solutions: By working collaboratively with stakeholders, it is possible to develop solutions that address both economic and environmental concerns, leading to a more sustainable project.

- Enhance Project Viability: Strong stakeholder engagement can help to ensure that the project is aligned with community needs and values, increasing its long-term viability.

Strategies for Communicating with Local Communities

Successful strategies for communicating with local communities involve a combination of transparency, active listening, and proactive engagement. This includes:

- Establishing a Dedicated Communication Channel: Creating a dedicated website, hotline, or email address for community members to ask questions and provide feedback. This demonstrates a commitment to open and ongoing communication.

- Hosting Public Meetings and Forums: Regularly holding public meetings and forums to provide updates on the project’s progress, address concerns, and gather feedback. This allows for direct interaction with community members and builds trust.

- Developing Educational Materials: Creating easily accessible materials that explain the project’s benefits, environmental mitigation measures, and job creation opportunities. This can help to address misinformation and dispel common misconceptions.

- Engaging with Local Leaders: Building relationships with local leaders and community groups to ensure that their concerns are heard and addressed. This can help to build trust and ensure that the project is aligned with community values.

- Implementing a Community Benefits Program: Developing a program that provides tangible benefits to the local community, such as job training, scholarships, or funding for local projects. This demonstrates a commitment to investing in the community and sharing the benefits of the project.