Xylem German wastewater beer is a fascinating concept that combines cutting-edge technology with a commitment to environmental sustainability. It explores the innovative ways that German breweries are utilizing Xylem’s wastewater treatment solutions to create a greener future for the brewing industry.

This approach tackles a critical issue: the significant amount of wastewater generated during beer production. Xylem’s technology not only cleanses this wastewater but also reduces energy consumption and minimizes the environmental impact of beer production. This article delves into the challenges and opportunities of wastewater treatment in Germany, the role of Xylem in sustainable brewing practices, and the potential for future advancements in this field.

Xylem and Wastewater Treatment: Xylem German Wastewater Beer

Wastewater treatment is a critical process for protecting public health and the environment. It involves removing pollutants from wastewater before it is discharged into rivers, lakes, or the ocean. Xylem, a leading global water technology company, plays a vital role in this process by providing innovative and sustainable solutions that enhance efficiency and reduce energy consumption.

Xylem’s Role in Wastewater Treatment

Xylem’s technologies and products are essential for various stages of wastewater treatment, from collection and conveyance to treatment and disposal. Xylem’s solutions contribute to:

- Efficient wastewater collection and conveyance:Xylem’s pumps, valves, and other equipment ensure the reliable and efficient transport of wastewater from homes and businesses to treatment plants. This reduces the risk of overflows and leaks, minimizing environmental contamination and public health risks.

- Effective wastewater treatment:Xylem’s advanced technologies, including membrane filtration, aeration systems, and disinfection solutions, enable efficient removal of pollutants from wastewater. These technologies improve the quality of treated water, ensuring it meets regulatory standards and can be safely discharged or reused.

- Sustainable wastewater management:Xylem’s solutions prioritize energy efficiency and resource conservation. By optimizing pumping systems, reducing energy consumption, and implementing water reuse strategies, Xylem helps wastewater treatment plants operate more sustainably and reduce their environmental footprint.

Examples of Xylem Products and Solutions

Xylem offers a wide range of products and solutions specifically designed for wastewater treatment, including:

- Flygt submersible pumps:These pumps are designed for reliable and efficient wastewater pumping in various applications, including sewage collection, lift stations, and treatment plant processes. They are known for their durability, high efficiency, and low maintenance requirements.

- Membranes:Xylem’s membrane filtration systems offer a highly efficient and reliable method for removing suspended solids, bacteria, viruses, and other contaminants from wastewater. They are used in various treatment processes, including microfiltration, ultrafiltration, and nanofiltration.

- Aeration systems:Xylem provides advanced aeration systems that enhance the oxygen transfer rate in wastewater treatment processes. These systems promote the growth of beneficial bacteria that break down organic matter and pollutants, improving treatment efficiency.

- Disinfection solutions:Xylem offers a range of disinfection technologies, including UV disinfection and chlorine disinfection, to ensure the treated wastewater meets regulatory standards for safe discharge or reuse. These technologies effectively eliminate harmful pathogens and bacteria, protecting public health and the environment.

German Wastewater Treatment Industry

Germany has a long history of wastewater treatment, with a robust infrastructure and stringent regulations in place. The country has a high level of awareness of the importance of protecting water resources, and wastewater treatment is seen as an essential part of environmental protection.

Current State of Wastewater Treatment

Germany has a highly developed wastewater treatment infrastructure, with a network of over 40,000 sewage treatment plants serving a population of over 80 million. The majority of these plants are operated by municipalities, with some private companies also involved in the sector.The German government has established strict regulations for wastewater treatment, which are enforced by the Federal Environment Agency (UBA).

These regulations cover a wide range of aspects, including the discharge limits for various pollutants, the design and operation of treatment plants, and the monitoring of wastewater quality.

Challenges Facing the German Wastewater Treatment Industry

The German wastewater treatment industry faces a number of challenges, including:

- Aging Infrastructure:Many of Germany’s wastewater treatment plants are aging and require significant investment to maintain and upgrade.

- Increasing Treatment Demands:The increasing use of pharmaceuticals and other emerging contaminants poses new challenges for wastewater treatment.

- Climate Change:Climate change is expected to increase the frequency and intensity of extreme weather events, which can impact the performance of wastewater treatment plants.

- Cost Pressures:The cost of operating and maintaining wastewater treatment plants is rising, putting pressure on municipalities and other operators.

Opportunities for the German Wastewater Treatment Industry

Despite the challenges, the German wastewater treatment industry also has a number of opportunities for growth and innovation:

- Investment in Infrastructure:The German government has committed to investing in the modernization and expansion of wastewater treatment infrastructure.

- Development of New Technologies:There is a growing demand for new and innovative wastewater treatment technologies to address emerging challenges.

- Circular Economy:Wastewater treatment can play a role in the circular economy by recovering valuable resources from wastewater.

- Energy Efficiency:There is significant potential to improve the energy efficiency of wastewater treatment plants.

Innovative Wastewater Treatment Technologies

Germany is a leader in the development and implementation of innovative wastewater treatment technologies. Some examples include:

- Membrane Bioreactors (MBRs):MBRs are a type of biological wastewater treatment that uses membranes to remove suspended solids and pathogens. MBRs are becoming increasingly popular in Germany due to their high efficiency and compact footprint.

- Advanced Oxidation Processes (AOPs):AOPs are a group of technologies that use strong oxidants to break down pollutants in wastewater. AOPs are particularly effective at removing emerging contaminants such as pharmaceuticals and pesticides.

- Nutrient Recovery Technologies:Nutrient recovery technologies can extract valuable nutrients from wastewater, such as phosphorus and nitrogen, for use as fertilizers.

- Integrated Wastewater Treatment Systems:Integrated wastewater treatment systems combine different treatment technologies to achieve optimal performance and resource recovery.

Beer Production and Wastewater

Brewing beer is a complex process that involves several stages, each contributing to the generation of wastewater. The wastewater generated during beer production is a significant environmental concern due to its high organic load, chemical contaminants, and potential for pollution.

Wastewater Generation in Beer Production

The brewing process generates wastewater at various stages, including:

- Malting:This stage involves soaking barley in water to germinate it. The water used for soaking and rinsing the barley is discharged as wastewater, containing high levels of organic matter, starches, and dissolved sugars.

- Mashing:This stage involves mixing the malted barley with hot water to extract fermentable sugars. The wastewater from this stage contains high levels of organic matter, starches, and dissolved sugars, along with enzymes and other byproducts of the mashing process.

- Lautering:This stage involves separating the liquid wort from the spent grain. The wastewater from lautering contains high levels of organic matter, suspended solids, and dissolved sugars.

- Boiling:This stage involves boiling the wort to concentrate it and remove unwanted compounds. The wastewater from boiling contains high levels of organic matter, suspended solids, and dissolved sugars, along with hop residues and other byproducts of the boiling process.

- Fermentation:This stage involves adding yeast to the wort to convert sugars into alcohol and carbon dioxide. The wastewater from fermentation contains high levels of organic matter, dissolved sugars, and yeast cells.

- Bottling/Kegging:This stage involves packaging the finished beer. The wastewater from bottling/kegging contains high levels of cleaning chemicals, detergents, and other residues from the packaging process.

Key Pollutants in Beer Wastewater, Xylem german wastewater beer

The wastewater generated during beer production contains various pollutants, including:

- Organic Matter:This includes sugars, starches, proteins, and other organic compounds that are readily biodegradable. The high organic load in beer wastewater can lead to oxygen depletion in receiving waters, creating conditions that are harmful to aquatic life.

- Suspended Solids:This includes grain residues, hop particles, yeast cells, and other solid materials. Suspended solids can contribute to turbidity in receiving waters, reducing light penetration and affecting aquatic plant growth.

- Nutrients:This includes nitrogen and phosphorus, which can stimulate excessive algal growth in receiving waters, leading to eutrophication and oxygen depletion.

- Chemicals:This includes cleaning chemicals, detergents, and other chemicals used in the brewing process. These chemicals can be toxic to aquatic life and may persist in the environment for long periods.

- Heavy Metals:This includes metals such as copper, iron, and zinc, which can be present in beer wastewater due to their use in brewing equipment or as additives. Heavy metals can accumulate in aquatic organisms and cause various health problems.

Environmental Impact of Beer Wastewater Discharge

The discharge of untreated beer wastewater into the environment can have significant negative impacts, including:

- Water Pollution:The high organic load in beer wastewater can lead to oxygen depletion in receiving waters, creating conditions that are harmful to aquatic life. The presence of suspended solids can also contribute to turbidity, reducing light penetration and affecting aquatic plant growth.

You also can understand valuable knowledge by exploring uk announces five quantum computing missions.

- Eutrophication:The high levels of nutrients in beer wastewater can stimulate excessive algal growth in receiving waters, leading to eutrophication and oxygen depletion.

- Toxicity:The presence of chemicals and heavy metals in beer wastewater can be toxic to aquatic life and may persist in the environment for long periods.

- Aesthetic Degradation:The discharge of beer wastewater can result in unpleasant odors and discoloration of receiving waters, affecting the aesthetic quality of the environment.

Sustainable Beer Production and Wastewater Management

In the pursuit of a greener future, the brewing industry is increasingly adopting sustainable practices to minimize its environmental impact. This involves not only optimizing beer production processes but also implementing efficient wastewater management strategies.

Sustainable Practices in Beer Production

Sustainable beer production aims to reduce resource consumption and waste generation throughout the brewing process. Key practices include:

- Water Conservation:Implementing water-efficient technologies such as high-efficiency spray nozzles, reducing water usage in cleaning and sanitation, and reusing process water where possible.

- Energy Efficiency:Utilizing renewable energy sources like solar and wind power, optimizing boiler and refrigeration systems, and implementing energy-saving measures in the brewery.

- Waste Reduction:Minimizing packaging waste through reusable containers, optimizing raw material usage to reduce byproducts, and implementing recycling programs for brewery waste.

- Sustainable Sourcing:Partnering with suppliers who prioritize sustainable practices, such as organic farming and responsible water usage, to ensure the responsible sourcing of raw materials.

Wastewater Treatment for Beer Production

Beer wastewater is a complex mixture of organic matter, suspended solids, and dissolved salts. Efficient wastewater treatment is crucial to minimize the environmental impact of brewing operations.

Xylem Technology for Beer Wastewater Treatment

Xylem offers a range of innovative technologies specifically designed for treating beer wastewater. These technologies can be integrated into a comprehensive system to achieve optimal treatment efficiency and minimize environmental impact.

A Sample System Design

A typical system for treating beer wastewater using Xylem technology might involve the following steps:

- Pretreatment:Removing large solids and grit through screening and sedimentation. This step prepares the wastewater for further treatment and prevents clogging in downstream processes.

- Biological Treatment:Using Xylem’s biological treatment systems, such as activated sludge or membrane bioreactors, to remove organic matter and reduce the biological oxygen demand (BOD) and chemical oxygen demand (COD) of the wastewater. These systems rely on microorganisms to break down organic pollutants into harmless byproducts.

- Filtration:Employing Xylem’s filtration technologies, such as membrane filtration or sand filtration, to remove suspended solids and other contaminants, ensuring a high-quality effluent. This step can also help remove dissolved pollutants, improving the overall water quality.

- Disinfection:Using Xylem’s UV disinfection systems to eliminate any remaining harmful microorganisms, ensuring the treated wastewater is safe for discharge or reuse.

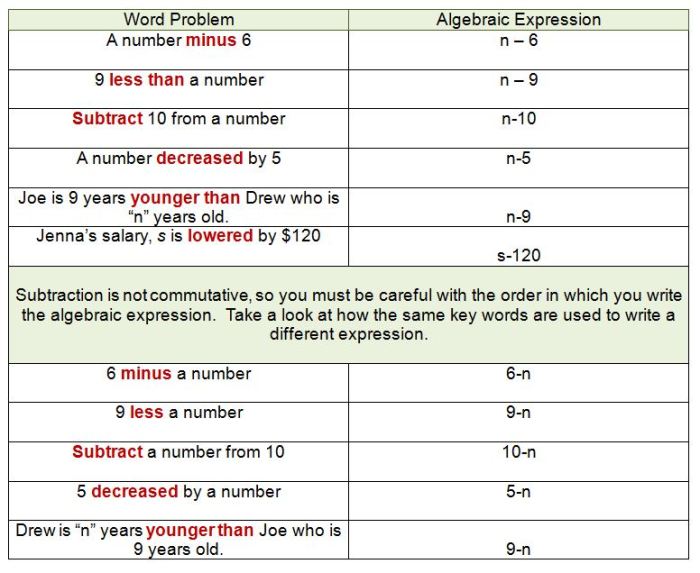

Comparison of Wastewater Treatment Methods

Different wastewater treatment methods are available for beer production, each with its advantages and disadvantages.

Table: Wastewater Treatment Methods for Beer Production

| Method | Advantages | Disadvantages |

|---|---|---|

| Activated Sludge | Cost-effective, efficient in removing organic matter, widely used. | Requires large footprint, potential for sludge disposal challenges, sensitive to shock loads. |

| Membrane Bioreactor (MBR) | High treatment efficiency, compact footprint, produces high-quality effluent. | Higher initial investment cost, potential for membrane fouling, requires regular maintenance. |

| Anaerobic Digestion | Produces biogas for energy generation, reduces sludge volume, suitable for high-strength wastewater. | Requires specialized equipment, longer treatment time, may not be suitable for all wastewater types. |

Case Studies of Xylem-Based Wastewater Treatment in German Breweries

The German brewing industry is renowned for its commitment to quality and sustainability. Many breweries are actively implementing innovative wastewater treatment solutions to minimize their environmental impact. Xylem, a leading provider of water technologies, plays a crucial role in this effort, offering a range of advanced solutions tailored to the specific needs of breweries.

Xylem’s Wastewater Treatment Solutions in German Breweries

Xylem’s wastewater treatment solutions for breweries are designed to address the unique challenges posed by the brewing process, including high organic loads, suspended solids, and potential contamination with heavy metals. These solutions are often customized to fit the specific needs of each brewery, taking into account factors such as production volume, wastewater characteristics, and available space.

- Membrane Bioreactors (MBRs):MBRs are a highly efficient technology that combines biological treatment with membrane filtration. They are particularly effective at removing suspended solids, organic matter, and nutrients from brewery wastewater.

- Activated Sludge Systems:Activated sludge systems use microorganisms to break down organic matter in wastewater. Xylem offers a range of activated sludge systems tailored to the specific requirements of breweries.

- Ultraviolet (UV) Disinfection:UV disinfection is a highly effective method for eliminating harmful pathogens from brewery wastewater. Xylem’s UV disinfection systems are designed to ensure complete inactivation of bacteria and viruses.

- Degritting and Screening:Xylem provides a variety of degritting and screening technologies to remove coarse solids from brewery wastewater, protecting downstream equipment and improving overall treatment efficiency.

Impact of Xylem-Based Wastewater Treatment on Environmental Sustainability and Cost-Effectiveness

Xylem’s wastewater treatment solutions for breweries contribute significantly to environmental sustainability and cost-effectiveness.

- Reduced Environmental Impact:Xylem’s technologies effectively remove pollutants from brewery wastewater, minimizing the discharge of harmful substances into the environment. This helps breweries comply with strict environmental regulations and protect local water resources.

- Resource Recovery:Xylem’s solutions can enable breweries to recover valuable resources from wastewater, such as water and nutrients. This reduces reliance on external resources and promotes a circular economy approach.

- Cost Savings:By optimizing wastewater treatment processes, Xylem’s technologies help breweries reduce operating costs associated with water and energy consumption.

Case Studies of Xylem-Based Wastewater Treatment in German Breweries

Here are some examples of German breweries that have successfully implemented Xylem’s wastewater treatment solutions:

- Brauerei Krombacher:Krombacher, one of Germany’s largest breweries, has implemented Xylem’s MBR technology to treat its wastewater. This has significantly reduced the brewery’s environmental impact and improved its overall sustainability performance.

- Brauerei Bitburger:Bitburger, another leading German brewery, has installed Xylem’s activated sludge system to treat its wastewater. This system effectively removes organic matter and nutrients, ensuring compliance with environmental regulations.

- Brauerei Beck & Co.:Beck & Co., a well-known German brewery, has adopted Xylem’s UV disinfection system to eliminate pathogens from its wastewater. This ensures the safe discharge of treated wastewater and protects local water resources.

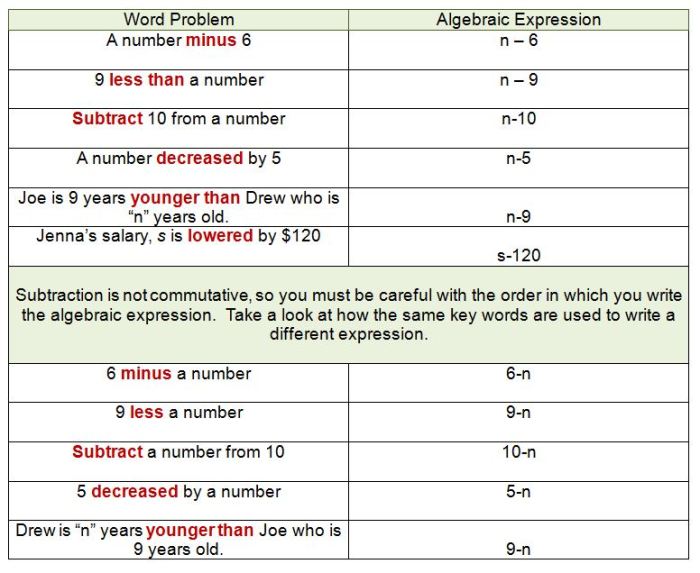

Key Features and Benefits of Xylem-Based Wastewater Treatment in German Breweries

The table below summarizes the key features and benefits of Xylem-based wastewater treatment solutions for German breweries:

| Feature | Benefit |

|---|---|

| Advanced Technologies | Highly effective at removing pollutants and pathogens |

| Customized Solutions | Tailored to the specific needs of each brewery |

| Energy Efficiency | Reduces energy consumption and operating costs |

| Resource Recovery | Enables breweries to recover valuable resources |

| Environmental Compliance | Helps breweries meet strict environmental regulations |

| Sustainability | Contributes to a more sustainable brewing industry |

Future Trends in Wastewater Treatment and Beer Production

The brewing industry is constantly evolving, with sustainability and resource efficiency becoming paramount. As a result, wastewater treatment technologies are rapidly advancing, offering innovative solutions to address the challenges posed by beer production. Xylem, a leading provider of water technologies, plays a crucial role in shaping the future of beer production by providing cutting-edge solutions for efficient and sustainable wastewater management.

Advancements in Wastewater Treatment Technologies

The future of wastewater treatment in the brewing industry is characterized by the integration of advanced technologies that optimize resource utilization and minimize environmental impact.

- Membrane Bioreactors (MBRs):MBRs are highly efficient systems that combine biological treatment with membrane filtration, resulting in high-quality effluent. They are particularly beneficial for breweries due to their ability to remove suspended solids, nutrients, and pathogens effectively.

- Advanced Oxidation Processes (AOPs):AOPs employ powerful oxidants like ozone or UV radiation to break down organic pollutants, including color and odor compounds present in brewery wastewater. This technology significantly enhances effluent quality and reduces the environmental burden.

- Bioaugmentation and Bioremediation:These techniques introduce specific microorganisms to enhance the degradation of recalcitrant pollutants in brewery wastewater. By optimizing microbial activity, these approaches can improve treatment efficiency and minimize the need for chemical additives.

Xylem’s Role in Shaping the Future of Beer Production

Xylem’s innovative technologies are transforming the brewing industry by providing comprehensive solutions for wastewater management.

- Smart Monitoring and Control Systems:Xylem’s intelligent monitoring and control systems provide real-time data on wastewater parameters, enabling breweries to optimize treatment processes, minimize energy consumption, and ensure compliance with regulations.

- Energy-Efficient Pumps and Blowers:Xylem offers a range of energy-efficient pumps and blowers specifically designed for wastewater treatment applications. These technologies reduce operational costs and minimize the environmental footprint of brewery operations.

- Sustainable Wastewater Reuse:Xylem’s technologies facilitate the reuse of treated wastewater for irrigation, cleaning, or other non-potable purposes, reducing water consumption and promoting a circular economy approach.

Potential Innovations and Advancements

The brewing industry is continuously exploring innovative solutions to optimize wastewater treatment and enhance sustainability.

- Closed-Loop Systems:The development of closed-loop systems that minimize water usage and maximize resource recovery is a promising area of research. These systems could enable breweries to recycle wastewater for process water, significantly reducing their environmental impact.

- Integration of Artificial Intelligence (AI):AI-powered systems can analyze real-time data from wastewater treatment processes, predict potential issues, and optimize treatment parameters for improved efficiency and reduced costs.

- Nanotechnology Applications:Nanotechnology holds immense potential for developing advanced materials and processes for wastewater treatment. For example, nanofiltration membranes can effectively remove contaminants, while nanomaterials can enhance the degradation of pollutants.